6

Considering the example shown in Fig 2, the sum

of the maximum voltage drop introduced by each

component in the loop must be less than the

minimum power supply voltage.

Min operating voltage of 2-wire flowmeter

10.0

Maximum voltage drop caused by controller

5.0

Maximum voltage drop caused by BA354ND

1.1

Maximum voltage drop caused by cables

0.4

_____

16.5V

At 20mA the power supply must therefore have an

output greater than 16.5V

4.2 Remote indication

The BA354ND rate totaliser may be driven from

any 4/20mA signal to provide a remote indication

of rate and total flow in a Zone 2 hazardous area.

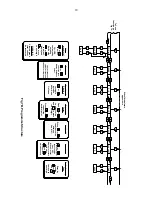

Fig 3A shows a typical application in which the

4/20mA output from a powered flowmeter drives a

BA354ND. Again it is necessary to ensure that the

4/20mA loop complies with the two design

requirements listed in section 4.1 If suitably

certified, the flowmeter may also be located in

Zone 2 as shown in Fig 3B.

Both examples show an external reset switch.

Alternatively the BA354ND may be programmed

so that the total display can be reset from the

internal push-buttons – see section 4.3.

Fig 3A

Remote indication from flowmeter in

safe area

Fig 3B

Remote indication from flowmeter in

Zone 2

4.3 Resetting the total display to zero

The BA354ND may be programmed to reset the

total display to zero when the

Up

and

Down

buttons are pushed simultaneously for 2 seconds.

If the application requires the total display to be

reset via a key-switch or from a remote location,

this can be achieved by connecting an external

switch to terminals RS1 and RS2. This switch may

be located in Zone 2 or in the safe area providing it

and the associated wiring can withstand a 500V

rms insulation test, to frame or earth. Most

industrial push-buttons and key-switches comply

with this requirement.