20

80-0042-00, Rev. 06.9

Setting Loss of Signal Function, cont'd

1. Remove the control module cover.

2. Verify the position of jumper plug J1/J2. Use

J1 to select the move to position function or

J2 to select the stay in place function.

CAUTION

Never use both J1 and J2—damage

will result.

3. Connect 120 V ac to terminals 1 and 2.

4. Turn on 120 V ac power supply.

5. Connect the voltmeter between test points

TP1 and TP2. TP2 is positive.

6. Turn trim potentiometer R15 until the desired

trigger level is measured on the voltmeter.

The voltage scale is:

0 V = 0 milliamps

1 V = 4 milliamps

2 V = 8 milliamps

Turn the potentiometer clockwise to increase

the trigger voltage, counterclockwise to

decrease the trigger voltage.

7. Disconnect the input signal (if connected) so

that the LOS becomes active.

8. If LOS is set to stay in place, the actuator

output shaft will not move.

9. If LOS is set to move to position:

Turn trim potentiometer R16 until the desired

output shaft position is reached. Turn the

potentiometer clockwise to increase the

output shaft position, counterclockwise to

decrease the output shaft position.

10. Replace the control module cover.

STALL FUNCTION

(Model 42‑107 Only)

The Stall function for Model 42-107 actuators

provides protection for the actuator motor and

gearing in the event of a stalled condition. The

time to stall is set at 136 seconds, after which

power to the motor is turned off. The timer resets

automatically when the signal reverses or the

Handswitch is moved from Auto to Manual.

The stall time of 136 seconds is set by the

factory and requires Jumper J3/J4 on the control

board (see Figure 7, page 19) to be set to the J4

position. If this Jumper is set to the J3 position (not

recommended), the time to stall will be decreased

to 68 seconds, which may be shorter than the full-

stroke travel time of some actuators.

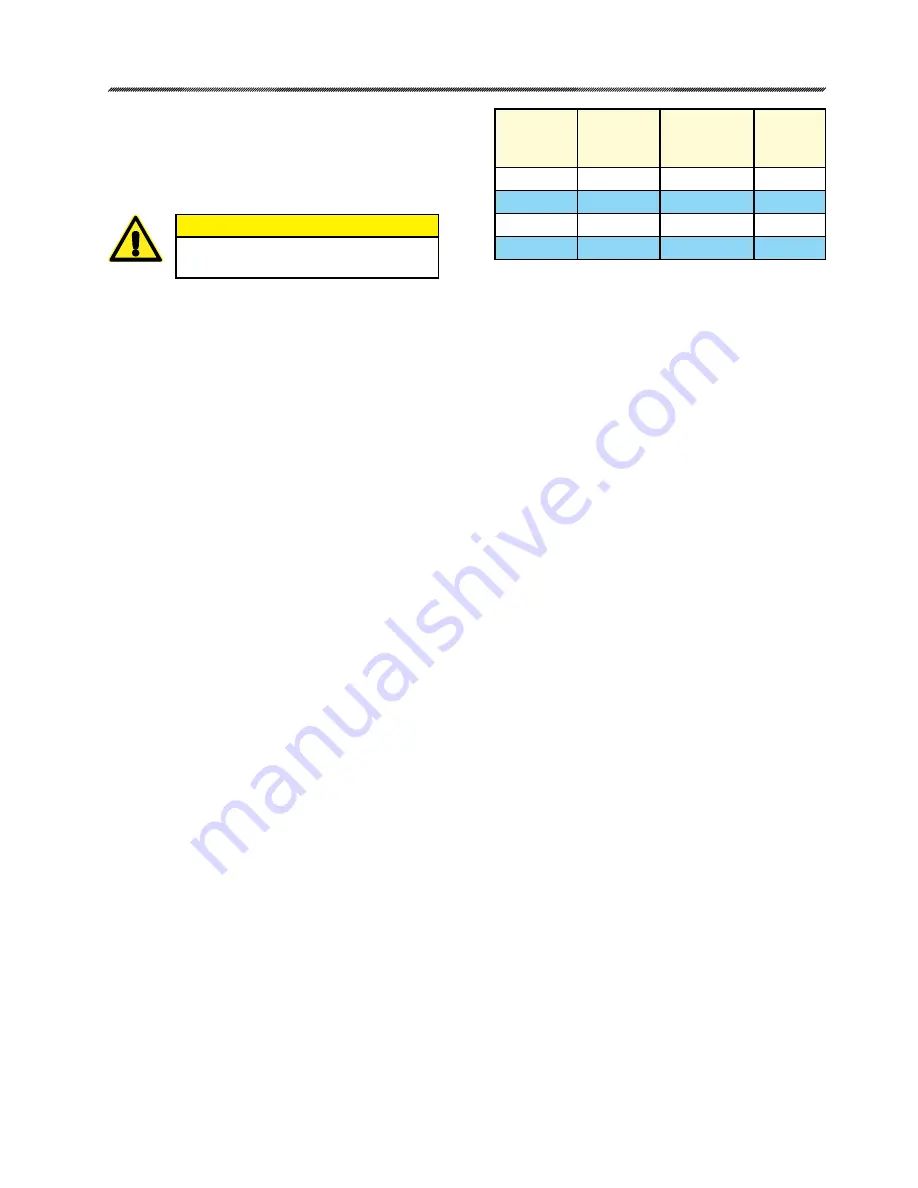

R20

Ω

Parallel

Resistor

Ω

Effective

Resistance

Ω

Dead‑

band

1,000,000

1.0%

1,000,000 2,000,000

666,000

1.5%

1,000,000 1,000,000

500,000

2.0%

1,000,000

665,000

400,000

2.5%

DEADBAND ADJUSTMENT

Group 42, Option 7 actuators are shipped

with the deadband set to 1% of span to satisfy

the requirements of most control systems. If

excessive process and/or signal noise is present,

the actuator may be subject to unnecessary

cycling. It is recommended that excessive noise

be reduced at the source in order to prevent

unnecessary cycling. This will improve process

control and prolong component life.

If it is not possible to eliminate the excessive

noise, the drive's deadband can be widened;

however, this will reduce the resolution of

the drive. Widening the deadband can be

accomplished by changing the value of resistor

R20 on the Control Board (see Figure 7). The

recommended procedure is to solder a second

resistor in parallel with the existing resistor R20.

The new resistance value, recommended parallel

resistor and corresponding deadband are listed

in the following chart.

SHORT‑STROKE OPERATION

(Reducing Full Stroke Travel Distance)

Typically, it is best to use the full travel of the

actuator in response to the 0–100% Demand

input signal. However, some set-ups and

applications make it necessary to reduce this

response to less than the maximum full travel

distance. To reduce the full travel of the actuator

(short-stroke), use the following procedure:

First, adjust the Extend Travel Limit Switch

(S4) to the setting necessary to accommodate

the reduced travel range (see page 12). Note:

If necessary, both the Retract (S3) and Extend

(S4) Switches may be adjusted.

Next, perform the Feedback Signal

Calibration in relation to the new switch

setting(s) to complete setting the reduced

travel distance (see page 16).

CALIBRATION