18

80-0042-00, Rev. 06.9

travel, the input signal should be 12 milliamps (3

volts) and at fully retracted, 4 milliamps (1 volt).

Split signal operation is also possible. The

control board can be adjusted to produce full

actuator travel with 50% of the input signal,

permitting two actuators to respond independently

from the same signal source. Split signal ranges

are:

4 to 12 milliamps (1 to 3 volts)

12 to 20 milliamps (3 to 5 volts)

It is also possible to calibrate the control

board to give a span anywhere between 8 and 16

milliamps (2 to 4 volts), with the minimum signal

between 4 and 12 milliamps (1 to 3 volts). The

maximum input signal may be anywhere between

12 and 20 milliamps (3 to 5 volts) as long as the

span is at least 8 milliamps (2 volts).

Tools required for calibration:

mA/V dc voltmeter

3/32 inch screwdriver

Large screwdriver

Table 1 lists the meter connections required for

the calibration procedure.

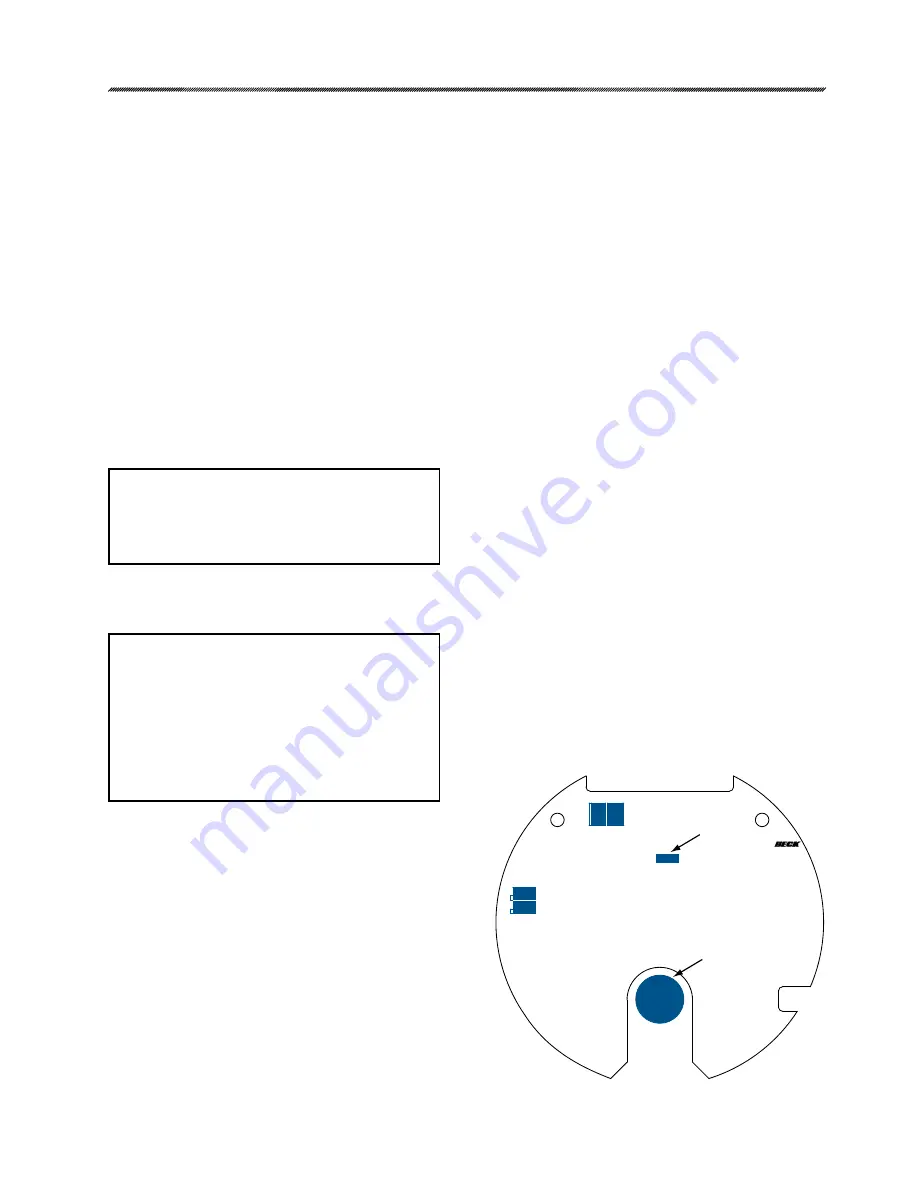

The calibration procedure requires setting

two trim potentiometers R13 and R14 on the

control board. Figure 7 shows the location of

these potentiometers and the Manual/Automatic

switches.

1. Remove the control module cover.

2. Set the Manual/Automatic toggle switch to

AUTOMATIC.

3. Connect a signal source to terminals 11 and

12, positive to 12.

4. Connect the meter to read the feedback

signal in accordance with Table 1, page 16.

Option 5 Control Board

Figure 6

FEEDBACK

POTENTIOMETER

1

1

CCW

CW

P4

P4

R38

R46

1

J6

J5

J5 / J6

Feedback Signal Calibration, cont'd

15. Position the actuator output shaft to the end

of travel limit that corresponds to 20 mA (i.e.,

to the fully extended position if the actuator

travel is set to extend on an increasing

demand signal, or to the fully retracted

position if the travel is set to retract). Allow

the over-travel limit switch to de-energize the

motor at the limit.

16. Turn trim potentiometer R38 counterclockwise

until the output signal is 20.05 mA ± .001

mA (5 volts on units configured for voltage

output).

17. Repeat steps 15 through 16 until the feedback

signal is calibrated. Adjusting R38 and R46

clockwise increases the signal while counter-

clockwise decreases the signal.

18. Reinstall resistor between terminals 13 and 14

(if used).

NOTE: The input signal is calibrated relative

to the feedback signal. Therefore the shaft

travel limit switches must be properly

adjusted and the feedback signal calibrated

before the input signal can be calibrated.

DEMAND INPUT SIGNAL CALIBRATION

(Option 7 only)

NOTE (Option 7): All actuators are fully

calibrated at the factory and should require

no adjustment; however, if necessary,

calibration may be tested as follows:

Apply 4.00 mA; actuator should position

at 4.00 mA ± .02 mA.

Apply 20.00 mA; actuator should position

at 20.00 mA ± .02 mA.

If adjustments are required, see below.

Input signal calibration is necessary to ensure

that the input signal correctly corresponds to the

position of the actuator output shaft.

Unless otherwise specified at the time of

order, all Group 42 actuators are shipped with the

input signal calibrated for full output shaft travel

and the input signal range set to 4 to 20 milliamps.

A 1 to 5 volt input signal may be specified at time

of order or changed at installation. To convert

a 4 -20 milliamp input configuration to 1-5 volts,

remove input resistor R1 from the terminal board.

To convert a 1-5 volt input configuration to 4-20

milliamps, install a 249 ohm resistor in position

R1. See Figure 5, page 16 for the location of R1.

When properly adjusted, the actuator output

shaft will be in the fully extended position when

the input signal is 20 milliamps (5 volts). At 50%

CALIBRATION