28

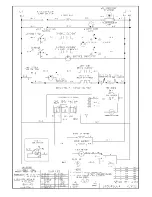

as adjustment (Conversion to LPG and flow adjustment)

All work must be carried out by a CORGI registered

engineer.

IMPO

supp

d/or adjusting the

inimum flow of the burners.

o

Remove the pan-stands, burners and

flame spreaders

(A)

.

o

U

and replace it

with the stipulated injector for the new gas

supply (see table below).

PRESSURE

(mbar)

INJECTOR

DIAMETRE

1/100mm

GAS

CONSUMPTION

POWER

(kW)

Max Min

G

RTANT: Always isolate the cooker from the electricity

ly before changing the injectors an

m

nscrew the injector

(B)

BURNER GAS

Auxiliary

Liquid gas-

G30

G 1

Nat. gas-

G20/G25

Town gas-

G110

G120

28 – 30

/

8

8

50

73 gr/h

1 0.3

3

37

20 25

70

126

120

95 dm³/h

227 dm³/h

Semi-rapid

Liquid gas-

G30

G

Nat. gas-

G20

5

Town gas-

G 0

G120

28 – 30

37

20/25

8

60

95

155

124 gr/h

162 dm³/h

385 dm³/h

1.7 0.32

31

/G2

11

8

150

Rapid

Liquid gas-

G30

G31

5

28

37

h

h

5

Nat. gas-

G20/G2

Town gas-

G110

G120

– 30

20/25

8

8

75

110

210

201

182 gr/h

238 dm³/

567 dm³/

2.5 0.

Wok

60

.6 0.7

Liquid gas-

G30

G31

5

Nat. gas-

G20/G2

Town gas-

G110

G120

28 – 30

37

20/25

8

8

92

135

290

2

262 gr/h

343 dm³/h

816 dm³/h

3

Summary of Contents for BT2740SS

Page 1: ...1 BT2740SS 90cm Multi function twin cavity cooking theatre ...

Page 37: ...37 ...

Page 38: ...38 ...

Page 39: ...39 ...

Page 40: ...40 ...