Set up instructions for the 714XLT

Baumfolder Corporation P.O. Box 728 1660 Campbell Rd, Sidney, Ohio USA 45365 Copyright © 2002

Phone 1-800-543-6107 or 1-937-492-1281 Fax 1-937-492-7280 email: [email protected]

If a sheet of paper is laid on a flat surface and driven into a stationary object, a buckle or a series of

buckles will form along the surface of the sheet.

If the paper is pushed into a narrow channel before butting up against the stationary object, the buckle

that forms in the channel will be a much smaller size than free-forming buckles. At the end of the

channel, however, larger buckles will again start to form.

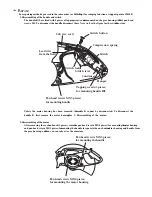

If the channel is angled to produce a down-ward pressure, and two folding rollers, spinning as indicated

above, are placed close to the end of the channel, the larger buckles that start forming there will always

form down-ward and be pulled into the rollers, compressing into a fold.

On a buckle folder (like the 714), the sheet comes out of the

feeder flat and enters the fold plate assembly where it comes to a

stop against a stationary fold stop. A series of buckles then forms

through the sheet. The buckles within the fold plate are kept very

small by the narrow channel design. The buckle at the end of the

plate, however, will be larger. The fold plate and rollers are

configured such that the large buckle will always form downward

where it is grabbed by the fold rollers and compressed into a fold.

The picture shows the second plate deflected. This would mean a

single fold.