Installation and Maintenance Manual: RLVAC

Published February 2022

11

3 Model: RLVAC

3.1 Overview

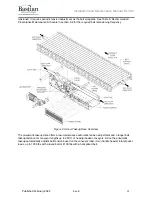

The Roller Live AC (RLVAC) conveyor is designed for longer runs of transport conveyor in applications

which require rollers instead of belted transport. RLVAC uses a continuous belt under the conveying

rollers driven by an AC gearmotor, which is engaged with the various conveying zones by means of

adjustable spring tension.

Figure 1: RLVAC Overview

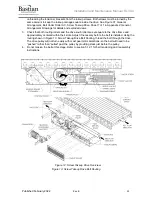

3.2 Belt

The main conveying belt is 99mm wide and is available with two different joining options.

The laced belt is quick to install and quick to repair, and does not require special tools or expertise with

the lacing factory installed. It is well suited for any conveyors within its load capacity (light to medium

product loads, or heavy loads on shorter conveyors).

The hot-spliced belt requires special tools and skills to create splices, and cannot be installed or replaced

as rapidly due to the minimum time for the splices to heat and cool. However, it is a more durable option

that is necessary for very heavy loads (working strength of the hot splice is about 2.7 times the working

strength of the lacing) and is maintenance-free for the life of the belt. The hot-spliced belt is also quieter

because there is no metal lacing contacting the conveying rollers.

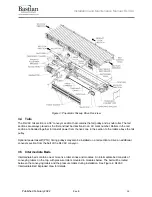

3.3 Drive Section

Two different drive designs are available for RLVAC conveyors. The screw (fixed) takeup drive is the least

expensive option and is available for conveyor lengths up to 100 ft and total product loads up to 1050 lbs

with a laced belt or 3200 lbs with a hot-spliced belt. Because the screw takeup drive is manually