8

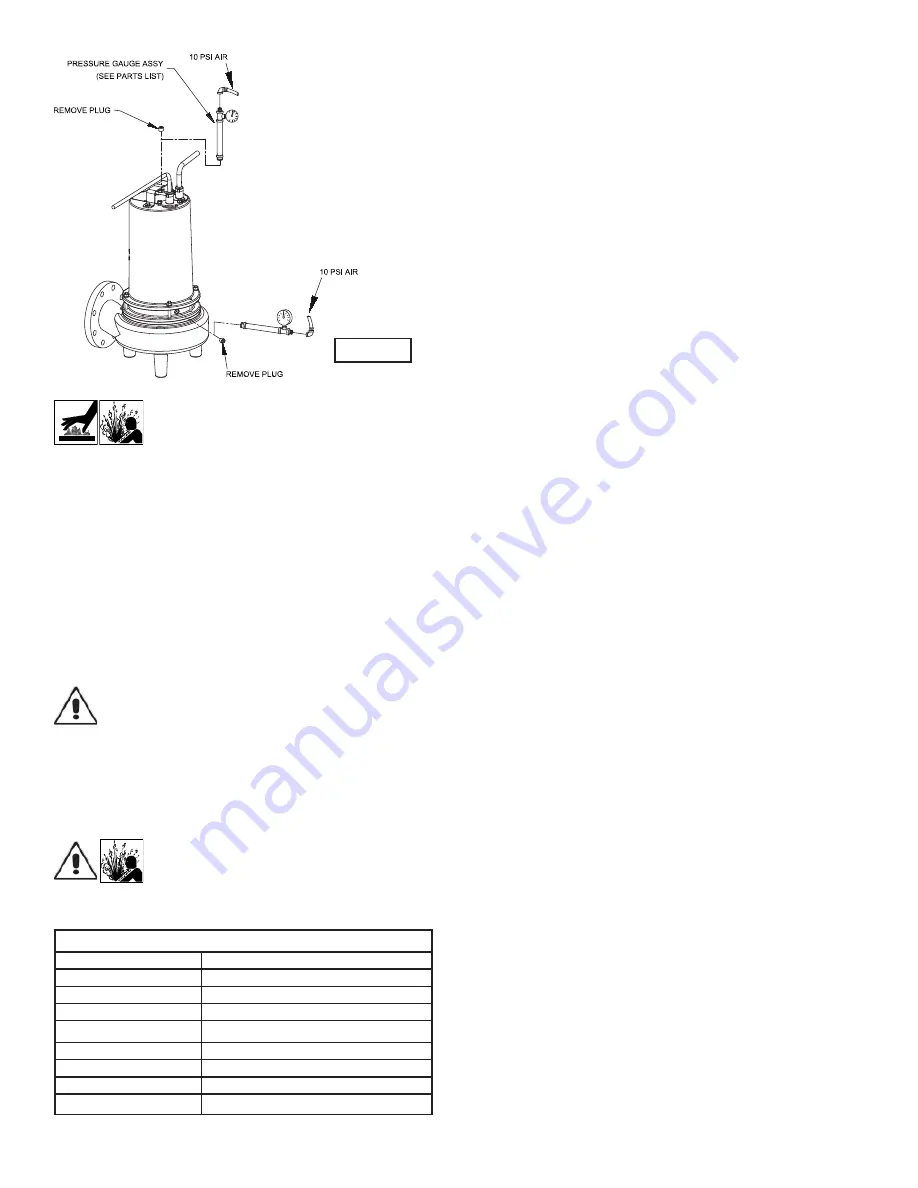

CAUTION! - Pressure builds up extremely

fast, increase pressure by “Tapping” air

nozzle. Too much pressure will damage

seal. DO NOT exceed 10 P.S.I.

Seal Chamber -

Set unit on its side with

fi

ll pipe plug (5)

downward, remove pipe plug (5) and drain all oil from seal

chamber. Apply pipe sealant to pressure gauge assembly

and tighten into hole in bearing bracket (20). Pressurize seal

chamber to 10 P.S.I. and check for leaks as outlined above.

F-1.4) Replacing Oil:

Motor Housing -

Set unit upright and re

fi

ll with new cooling

oil as per Table 1 (see parts list for amount). Fill to just above

motor as an air space must remain in the top of the motor

housing to compensate for oil expansion (see Figure 2 or 12).

Apply pipe thread compound to threads of pipe plug (5) then

assemble to motor housing (2).

IMPORTANT! - For single phase units, oil level

should be below capacitor.

Seal Chamber -

Set unit on its side, with pipe plug (5)

upward, and re

fi

ll with new oil as per Table 1 (see parts list for

amount). Apply pipe thread compound to threads of pipe plug

(5) and assemble to bearing bracket (20).

WARNING! - DO NOT over

fi

ll oil.

Over

fi

lling of motor housing with oil can

create excessive and dangerous hydraulic

pressure which can destroy the pump

and create a hazard. Over

fi

lling oil voids

warranty.

TABLE 1 - COOLING OIL - Dielectric

SUPPLIER

GRADE

Sohio / Standard

SE 40, Energol HL22 or HL32

Shell

Turbo Oil 32

Texaco

Rando HD32, 522

Sun Petroleum

Supar 110, Sunvis 816WR, 911 or 916

Mobile

D.T.E. Oil Light or Rubrex 200

G&G

Circu Oil 22

Allegheny Petroleum

Altrapar 22

Woco

Premium 100

F-2) Impeller and Volute Service:

F-2.1) Disassembly and Inspection:

To clean out volute (25) disconnect power, remove hex nuts

(19), and lock washers (18), vertically lift motor and seal plate

assembly from volute (25). Clean out volute if necessary.

Clean and examine impeller (27), for pitting or wear and

replace if required, inspect square ring (36) and replace if

cut or damaged. If the impeller (27) needs replacing, remove

hex nut (33), and washer (22) . The impeller is keyed onto

the shaft with a square key (32) and to remove, pull impeller

straight off the shaft using a wheel puller, if required. Before

reinstalling, check the motor shaft and impeller bore for

damage.

F-2.2) Reassembly:

To install impeller (27), apply a thin

fi

lm of oil to motor shaft and

slide impeller straight onto shaft, keeping lined up. Drive key

(32) into keyway. Locate washer (22) thread locking compound

to shaft threads, thread hex nut (33) to shaft and torque to 40

ft.-lbs. Rotate impeller to check for binding.

Position square ring (36) on volute

fl

ange and install impeller

and motor housing over studs and onto volute (25). Apply

thread locking compound to threads of each stud (24). Install

lock washers (33) and thread nuts (20) onto stud (23). Torque

30 ft.-lbs. Check for free rotation of motor and impeller.

F-3) Motor and Bearing Service:

F-3.1) Disassembly and Inspection:

To examine or replace the motor (1), capacitor (3, 1 phase

units), and bearing (39), drain oil from motor as outlined

in paragraph F-1.2. Disassemble volute and impeller as

outlined in paragraph F-2.1 and disassemble shaft seal

as outlined in paragraph F-4.1. Position unit upright, using

blocks to avoid resting unit on shaft. Unscrew cable hex bolts

(6) and remove compression

fl

ange (9a) and power cord

(9). Remove snap ring (51) with a

fl

at head screwdriver. Pull

the terminal block (26) out of the motor housing (2) using a

T-bolt or pair of pliers and a .25-20 screw in the threads of

the terminal block (26). Be sure to leave slack on the motor

leads connected underneath. Use needle nose pliers to pull

each female connector off of the pins on the underside of the

terminal block (26) (see Figure 5). The unit voltage should be

noted. Repeat cord and terminal removal procedure for any

sensor cords (10). Remove socket head cap screws (42).

Vertically lift motor housing from bearing bracket by lifting

handle (7). Inspect square rings (36) for damage or cuts.

Remove the motor bolts and lift motor stator from bearing

bracket (20). Disconnect capacitor leads from capacitor (3, 1

phase units). Examine bearing (39) and replace if required.

If replacement is required, remove bearing (39) from motor

shaft using a wheel puller or arbor press. (see Figure 4)

FIGURE 2

Summary of Contents for 3SE3054DS

Page 12: ...12 FIGURE 11 ...

Page 20: ...20 Notes ...