5

SECTION B: GENERAL INFORMATION

B-1) To the Purchaser:

Congratulations!

You are the owner of one of the fi nest

pumps on the market today. Barnes® Pumps are products

engineered and manufactured of high quality components.

Over one hundred years of pump building experience

along with a continuing quality assurance program combine

to produce a pump which will stand up to the toughest

applications.

This manual will provide helpful information concerning

installation, maintenance, and proper service guidelines.

B-2) Receiving:

Upon receiving the pump, it should be inspected for

damage or shortages. If damage has occurred, fi le a claim

immediately with the company that delivered the pump. If

the manual is removed from the packaging, do not lose or

misplace.

B-3) Storage:

Short Term-

Barnes pumps are manufactured for effi cient

performance following short inoperative periods in storage.

For best results, pumps can be retained in storage, as factory

assembled, in a dry atmosphere with constant temperatures

for up to six (6) months.

Long Term-

Any length of time exceeding six (6) months, but

not more than twenty four (24) months. The units should be

stored in a temperature controlled area, a roofed over walled

enclosure that provides protection from the elements (rain,

snow, wind-blown dust, etc.), and whose temperature can be

maintained b40 deg. F and +120 deg. F.

If extended high humidity is expected to be a problem, all

exposed parts should be inspected before storage and all

surfaces that have the paint scratched, damaged, or worn

should be recoated with a water base, air dry enamel paint.

All surfaces should then be sprayed with a rust-inhibiting oil.

Pump should be stored in its original shipping container. On

initial start up, rotate impeller by hand to assure seal and

impeller rotate freely.

B-4) Service Centers:

For the location of the nearest Barnes Service Center, check

your Barnes representative or Crane Pumps & Systems, Inc.,

Service Department in Piqua, Ohio, telephone (937) 778-8947

or Crane Pumps & Systems Canada, Inc., in Bramton, Ontario

(905) 457-6223.

SECTION C: INSTALLATION:

C-1) Location:

The pump should be located as near as possible to the liquid

to be pumped and in no case should the pump be more than

15 feet above the surface of the liquid supply. The pump

should always be as level as possible.

C-2) Suction System:

Connect suction pipe or hose to suction inlet. If hose is used,

it should be of the reinforced type to prevent collapsing under

suction. Make sure all suction system connections are tight

and free of air leaks, as even a very slight leak will greatly

reduce priming ability and pumping effi ciency.

CAUTION! - This pump should not be operated

without a strainer on the end of the suction line

to prevent sticks, stones, rags and other foreign

matter from being drawn into the impeller. The

strainer should be cleaned regularly to insure full fl ow.

C-3) Discharge System:

Connect discharge hose or pipe to discharge opening in

pump.

C-4) Lubrication:

The pump requires no lubrication. It is equipped with a

mechanical shaft seal which is lubricated by the liquid being

pumped. Lubrication of the engine should be as indicated in

the Engine Manual.

CAUTION! - DO NOT operate pump without liquid

in the pump body as operating pump dry will

result in damage to the seal.

SECTION D: OPERATION:

D-1) Priming:

Start engine; holding governor open for maximum speed will

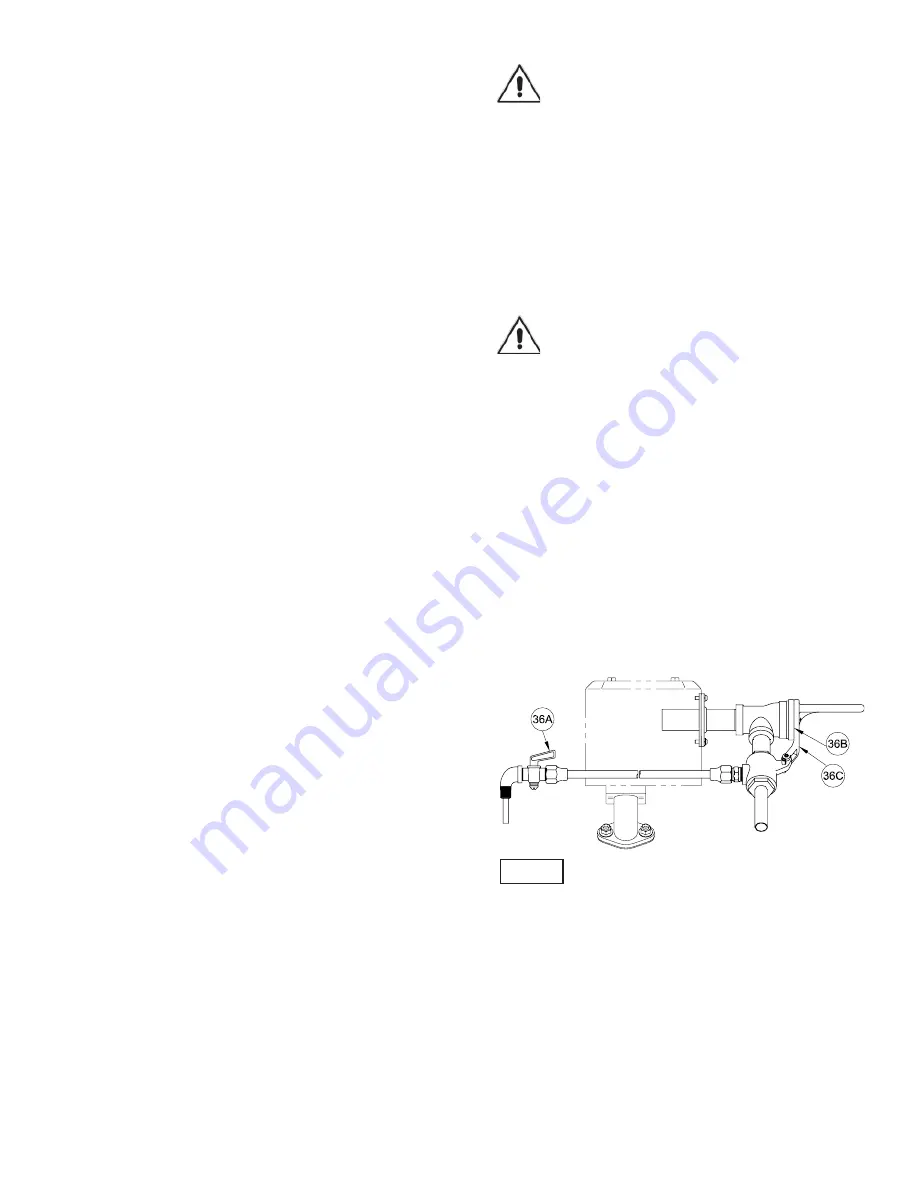

decrease priming time. Open gas cock (36A) in line between

pump suction and exhaust primer (36), (See Figure 1). With

exhaust primer handle (36B) and cap (36C), close exhaust

opening, this diverts engine exhaust gasses through the

venturi which creates a vacuum in the pump. When a steady

spray of water is coming from the primer, open the exhaust

and close the gas cock. (Delay the procedure if spray is

not full and steady or false prime will result.) Full prime

can usually be detected by the engine “LOADING UP” as

pumping action begins.

SECTION E: PUMP SERVICE AND REPAIR:

E-1) Check Valve Service:

Remove cap screws (20) and pull check valve body (19)

from pump body (14).

CAUTION:

Do not pry with sharp

instrument, but rather bump off with a block of wood and

a hammer. This will expose the check valve assembly for

examination or repair.

Examine and replace any part showing wear or damage.

At reassembly. make sure that the LARGE weight is on the

CHECK VALVE BODY side of the gasket and that the HINGE

section of gasket is at TOP.

EXHAUST PRIMER ITEM (36)

Figure 1

Summary of Contents for 2020HC

Page 8: ...8 Figure 3 ...