Manual

2100-365Q

Page

35 of 73

ROUTINE MAINTENANCE

1. Air Filters – Check the condition at least monthly

when the unit is in use, and replace as necessary.

2. Lubrication Requirements – The indoor circulating

air blower motor and outdoor circulating air fan

motor are permanently lubricated and requires no re-

oiling. The combustion air blower motor requires no

re-oiling.

ROUTINE INSPECTION

1. Inspect the physical support of the unit annually to

make sure it is securely fastened to the building.

Also look for any obvious signs of deterioration.

2.

Inspect the main burners at the beginning of each

heating season and clean as necessary.

3. Inspect the vent terminal and combustion air intake

hood for any obvious deterioration, to make sure it is

free and clear of any obstructions.

29. REPLACEMENT PARTS

ANNUAL MAINTENANCE

Routine inspection and maintenance procedures are the

responsibility of the user and are outlined below.

1. Before inspecting unit:

a. Turn room thermostat to lowest or off setting.

b. Turn off equipment gas shut off valve.

c. Wait for unit to cool if it was recently

operating.

d. Turn off electrical power to unit.

2. Inspect the following:

a. Vent terminal and combustion air intake

terminal. Make sure both are free from

obstructions.

b. Vertical Vent Applications – Inspect venting

system. Make sure system has no holes, is

physically sound and free from obstructions.

c. Make sure the supply and return air flange

sleeves or duct work are securely fastened to

unit and physically sound.

d. Supply and return grilles must be open and

free from obstructions.

e. Inspect to make sure the unit is securely

fastened to the wall. Seal any possible leaks

between unit and wall with appropriate

exterior sealing material.

f.

Inspect burners, heat exchanger, induced

draft blower, and induced draft blower

collector box. There must be no obvious

signs of deterioration.

g. Inspect all electrical connections and wiring.

h. Check all gas piping for leaks with soap

solution used to detect leaks.

i.

Inspect, clean, and repair as needed the entire

blower assembly, air filters, draft inducer,

cooling coils, and vent options (if installed).

Replacement parts for the gas/electric units are

available through local distributors.

A replacement parts list manual is supplied with each

unit. When ordering parts or making inquires

pertaining to any of the units covered by these

instructions, it is very important to always supply the

complete

model number and serial number of the unit.

This is necessary to assure that the correct parts (or an

approved alternate part) are issued to the service

agency.

WARNING

Disconnect electrical power before servicing

unit. Failure to do so could result in electrical

shock or death.

WARNING

Turn off electrical power supply to prevent

injury from moving parts or electric shock.

WARNING

Use replacement parts listed in Replacement

Parts list. Failure to do so could cause

improper furnace operation, resulting in

property damage, personal injury, or death.

Summary of Contents for WG242-A

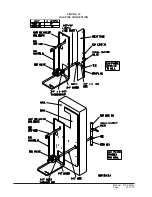

Page 13: ...Manual 2100 365Q Page 13 of 73 FIGURE 2A MOUNTING INSTRUCTIONS FOR WG42 WG48 AND WG60...

Page 16: ...Manual 2100 365Q Page 16 of 73 FIGURE 6 COMMON WALL MOUNTING INSTALLATIONS...

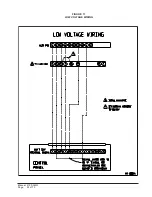

Page 22: ...Manual 2100 365Q Page 22 of 73 FIGURE 11 LOW VOLTAGE WIRING...

Page 23: ...Manual 2100 365Q Page 23 of 73 FIGURE 12 GAS PIPE CONNECTION...

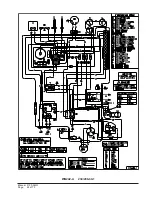

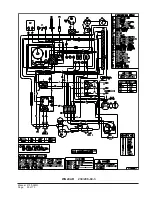

Page 48: ...Manual 2100 365Q Page 48 of 73 WG242 A 230 208 60 1...

Page 49: ...Manual 2100 365Q Page 49 of 73 WG242 A WG362 A 230 208 60 1...

Page 50: ...Manual 2100 365Q Page 50 of 73 WG242 B 230 208 60 3...

Page 51: ...Manual 2100 365Q Page 51 of 73 WG242 B WG362 B 230 208 60 3...

Page 52: ...Manual 2100 365Q Page 52 of 73 WG243 C 460 60 3...

Page 53: ...Manual 2100 365Q Page 53 of 73 WG243 C 460 60 3...

Page 54: ...Manual 2100 365Q Page 54 of 73 WG302 A 230 208 60 1...

Page 55: ...Manual 2100 365Q Page 55 of 73 WG302 A WG482 A WG602 A 230 208 60 1...

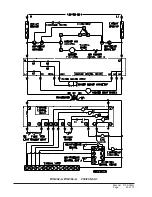

Page 56: ...Manual 2100 365Q Page 56 of 73 WG302 B 230 208 60 3...

Page 57: ...Manual 2100 365Q Page 57 of 73 WG302 B WG482 B WG602 B 230 208 60 3...

Page 58: ...Manual 2100 365Q Page 58 of 73 WG303 C 460 60 3...

Page 59: ...Manual 2100 365Q Page 59 of 73 WG303 C 460 60 3...

Page 60: ...Manual 2100 365Q Page 60 of 73 WG362 A 230 208 60 1...

Page 61: ...Manual 2100 365Q Page 61 of 73 WG362 B 230 208 60 3...

Page 62: ...Manual 2100 365Q Page 62 of 73 WG363 C 460 60 3...

Page 63: ...Manual 2100 365Q Page 63 of 73 WG363 C 460 60 3...

Page 64: ...Manual 2100 365Q Page 64 of 73 WG423 A 230 208 60 1...

Page 65: ...Manual 2100 365Q Page 65 of 73 WG423 A 230 208 60 1...

Page 66: ...Manual 2100 365Q Page 66 of 73 WG423 B 230 208 60 3...

Page 67: ...Manual 2100 365Q Page 67 of 73 WG423 B 230 208 60 3...

Page 68: ...Manual 2100 365Q Page 68 of 73 WG424 C 460 60 3...

Page 69: ...Manual 2100 365Q Page 69 of 73 WG424 C 460 60 3...

Page 70: ...Manual 2100 365Q Page 70 of 73 WG482 A WG602 A 230 208 60 1...

Page 71: ...Manual 2100 365Q Page 71 of 73 WG482 B WG602 B 230 208 60 3...

Page 72: ...Manual 2100 365Q Page 72 of 73 WG483 C WG603 C 460 60 3...

Page 73: ...Manual 2100 365Q Page 73 of 73 WG483C WG603 C 460 60 3...