Manual 2100-419E

Page

40 of 48

COOLING TOWER / BOILER

APPLICATION

The cooling tower and boiler water loop temperature is

usually maintained between 50°F to 100°F to assure

adequate cooling and heating performance.

In the cooling mode, heat is rejected from the unit into

the source water loop. A cooling tower provides

evaporative cooling to the loop water thus maintaining a

constant supply temperature to the unit. When utilizing

open cooling towers chemical water treatment is

mandatory to ensure the water is free from corrosive

minerals.

It is imperative that all air be eliminated from the source

closed loop side of the heat exchanger to insure against

fouling.

CAUTION

Water piping exposed to extreme low ambient

temperatures are subject to freezing.

Units are equipped with female pipe thread fittings.

Consult the specification sheets for sizes. Teflon tape

sealer should be used when connection to the unit to

insure against leaks and possible condenser fouling. Do

not overtighten the connections. Flexible hoses should

be used between the unit and the rigid system to avoid

possible vibration. Ball valves should be installed in the

supply and return lines for unit isolation and unit water

flow rate balancing.

Pressure / temperature ports are recommended in both

supply and return lines for system flow balancing.

Water flow can be accurately set by measuring the

refrigerant to water heat exchangers water side pressure

drop. See Table 9 for water flow and pressure drop

information.

WARNING

Thin ice may result in the vicinity of the

discharge line.

For complete information on water well systems and

lake and pond applications, refer to Manual 2100-078

available from your distributor.

L. Where the local conditions prevent the use of a

gravity drainage system to a lake or pond, you can

instead run standard plastic piping out into the pond

below the frost and low water level.

In the heating mode, heat is absorbed from the source

water loop. A boiler can be utilized to maintain the loop

at the desired temperature. In milder climates a

“flooded tower” concept is often used. This concept

involves adding makeup water to the cooling tower

sump to maintain the desired loop temperature.

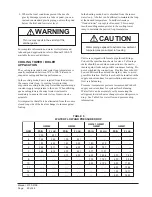

TABLE 9

WATER FLOW AND PRESSURE DROP

M

P

G

2

4

2

W

Q

2

0

3

W

Q

,

1

2

4

W

Q

,

1

6

3

W

Q

1

8

4

W

Q

1

0

6

W

Q

G

I

S

P

.

d

H

.

t

F

G

I

S

P

.

d

H

.

t

F

G

I

S

P

.

d

H

.

t

F

G

I

S

P

.

d

H

.

t

F

3

0

0

.

1

1

3

.

2

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

4

2

4

.

1

8

2

.

3

0

0

.

1

1

3

.

2

-

-

-

-

-

-

-

-

-

-

-

-

5

3

8

.

1

2

2

.

4

3

4

.

1

0

3

.

3

0

8

.

1

5

1

.

4

-

-

-

-

-

-

6

4

2

.

2

7

1

.

5

6

8

.

1

9

2

.

4

8

2

.

3

7

5

.

7

-

-

-

-

-

-

7

6

6

.

2

4

1

.

6

0

3

.

2

1

3

.

5

7

7

.

4

1

0

.

1

1

-

-

-

-

-

-

8

-

-

-

-

-

-

3

7

.

2

0

3

.

6

6

2

.

6

6

4

.

4

1

0

3

.

3

3

6

.

7

9

-

-

-

-

-

-

-

-

-

-

-

-

5

7

.

7

0

9

.

7

1

0

3

.

4

4

9

.

9

0

1

-

-

-

-

-

-

-

-

-

-

-

-

4

2

.

9

4

3

.

1

2

0

0

.

5

5

5

.

1

1

1

1

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

0

0

.

6

6

8

.

3

1

2

1

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

0

0

.

7

7

1

.

6

1

3

1

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

0

2

.

8

5

9

.

8

1

Summary of Contents for QW242

Page 6: ...Manual 2100 419E Page 6 of 48 FIGURE 1 UNIT DIMENSIONS ...

Page 21: ...Manual 2100 419E Page 21 of 48 FIGURE 15 REMOTE THERMOSTAT WIRING DIAGRAM X OPTION ...

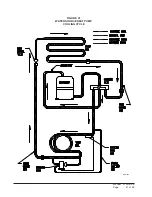

Page 41: ...Manual 2100 419E Page 41 of 48 FIGURE 27 WATER SOURCE HEAT PUMP COOLING CYCLE MIS 329 ...

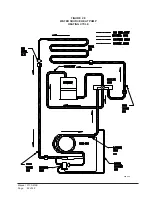

Page 42: ...Manual 2100 419E Page 42 of 48 FIGURE 28 WATER SOURCE HEAT PUMP HEATING CYCLE MIS 328 ...