Manual 2100-419E

Page

32 of 48

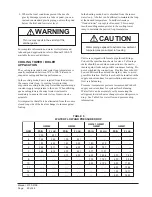

CIRCULATION SYSTEM DESIGN

Equipment room piping design is based on years of

experience with earth coupled heat pump systems. The

design eliminates most causes of system failure.

Surprisingly, the heat pump itself is rarely the cause.

Most problems occur because designers and installers

forget that a closed loop earth coupled heat pump

system is

not

like a household plumbing system.

Most household water systems have more than enough

water pressure either from the well pump of the

municipal water system to overcome the pressure of

head loss in 1/2 inch or 3/4 inch household plumbing.

A closed loop earth coupled heat pump system,

however, is separated from the pressure of the

household supply and relies on a small, low wattage

pump to circulate the water and antifreeze solution

through the earth coupling, heat pump and equipment

room components.

The small circulator keeps the operating costs of the

system to a minimum. However, the performance of the

circulator

must

be closely matched with the

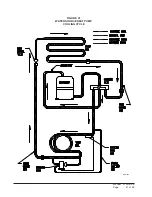

FIGURE 20

CIRCULATION SYSTEM

pressure of head loss of the entire system in order to

provide the required flow through the heat pump.

Insufficient flow through the heat exchanger is one of

the most common causes of system failure. Proper

system piping design and circulator selection will

eliminate this problem

Bard supplies a work sheet to simplify head loss

calculations and circulator selection. Refer to

“Circulating Pump Work sheet” section in manual

2100-099.

COPPER WATER COIL APPLICATION

Copper water coils are available as a factory installed

option. The unit model number will indicate the coil

option as the next to last character; “X” is for standard

coil constructed of Cupronickel material and “4” is from

a water coil constructed of copper.

The Cupronickel coil is suitable for all applications.

The copper coil is suitable for applications using

ground loop and cooling tower only and is never to

be used in an open well application.

CLOSED LOOP

(Earth Coupled Ground Loop Applications)

PIPE FROM GROUND LOOP

PIPE TO GROUND LOOP

PUMP MODULE

(See Spec Sheet for Model No.)

UNIONS

1” FLEXIBLE HOSE

Summary of Contents for QW242

Page 6: ...Manual 2100 419E Page 6 of 48 FIGURE 1 UNIT DIMENSIONS ...

Page 21: ...Manual 2100 419E Page 21 of 48 FIGURE 15 REMOTE THERMOSTAT WIRING DIAGRAM X OPTION ...

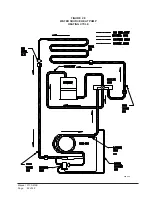

Page 41: ...Manual 2100 419E Page 41 of 48 FIGURE 27 WATER SOURCE HEAT PUMP COOLING CYCLE MIS 329 ...

Page 42: ...Manual 2100 419E Page 42 of 48 FIGURE 28 WATER SOURCE HEAT PUMP HEATING CYCLE MIS 328 ...