R55F Series Fiber-Optic Color Mark Sensors

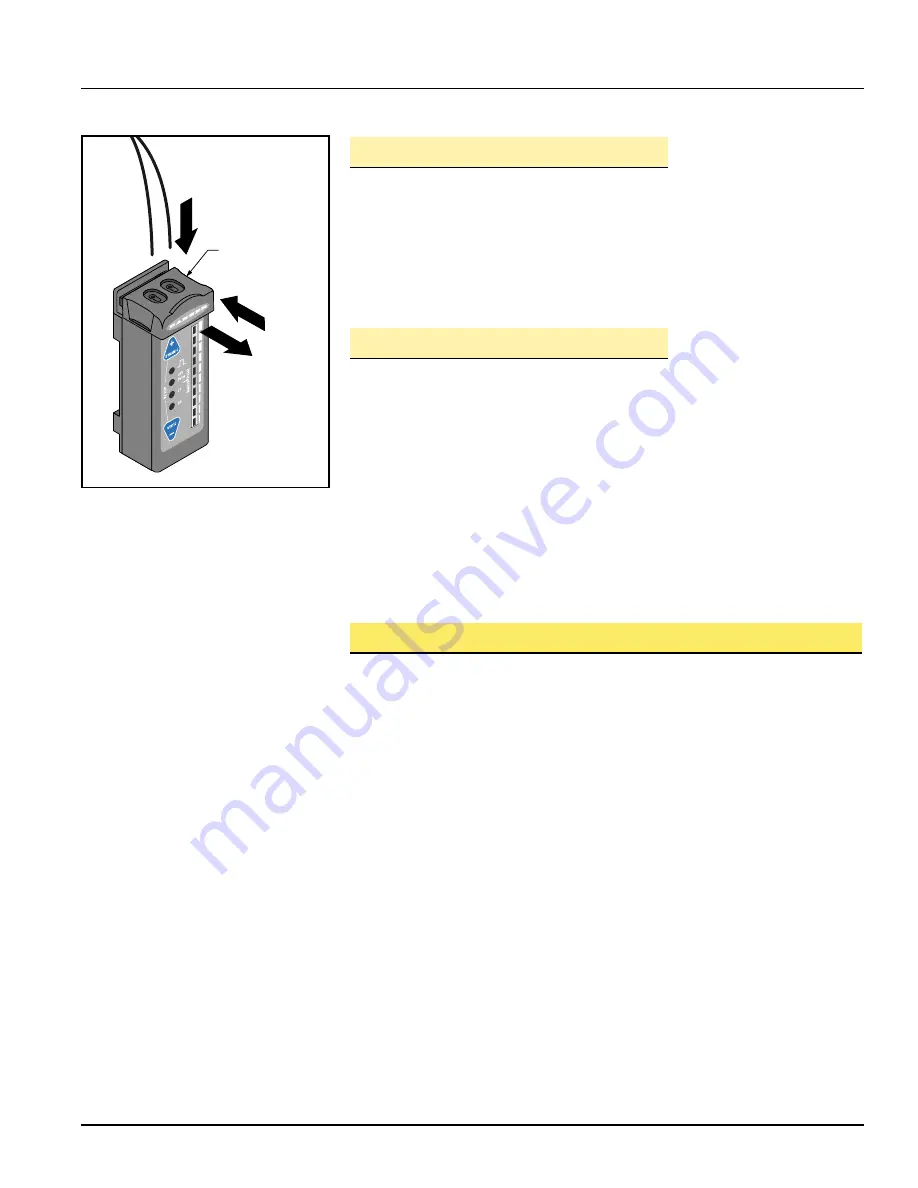

A

B

C

Fiber

Clip

Figure 1. Installing fibers into the R55F

Series sensor

Plastic fibers

shown; procedure

is identical for

glass fibers

Glass Fiber Installation Procedure:

1) Check to see that a rubber o-ring is pre-installed on each fiber control end.

2) Slide the fiber clip to the open position (A).

3) Insert one fiber end into each port (B). Push firmly on the fiber ends to compress

the o-rings and align the grooves in the fiber ends with the slot in the fiber clip.

4) Slide the fiber clip back into place, locking the fibers into position (C).

Plastic Fiber Installation Procedure:

NOTE: R55F sensors accept 0.75, 1.0, and 1.5 mm (0.03", 0.04", and 0.06") core

diameter plastic fibers.

1) Cut the “control ends” (sensor ends) of the plastic fiber(s) to the desired length

per the procedure which accompanies the fiber assembly.

2) If not already done, separate bifurcated fibers by approximately 2" from the control

ends.

3) Slide the fiber clip to the open position (A).

4) Insert the fiber ends into each port and push them in as far as they will go (B).

5) Slide the fiber clip back into place, locking the fibers into position (C).

Fiber Optic Mounting Considerations

Mount the sensing end of the fiber optic assembly so that the light image is totally

contained within the boundaries of the color mark to be sensed. The light image is

made smaller by moving the sensing tip closer to the surface of the material to be

sensed.

When sensing marks on shiny (specular) materials, such as metal, plastic or glossy

paper, mount the sensing tip of the fiber at approximately 15° from perpendicular to

the material surface to minimize strong direct reflections.

Isolate the fiber mounting from vibration. Also, maintain mechanical stability of the

surface to be sensed (e.g., stabilize web flutter at the sensing point).

Buy: www.ValinOnline.com | Phone 844-385-3099 | Email: [email protected]