ANSI NFPA 79 Electrical Standard for Industrial Machinery

Contact: National Fire Protection Association, 1 Batterymarch Park, P.O. Box 9101, Quincy, MA 02269-9101, Tel.:

800-344-3555

ANSI/RIA R15.06 Safety Requirements for Industrial Robots and Robot Systems

Contact: Robotic Industries Association, 900 Victors Way, P.O. Box 3724, Ann Arbor, MI 48106, Tel.: 734-994-6088

Applicable International Standards

ISO 12100-1 & -2 (EN 292-1 & -2) Safety of Machinery – Basic Concepts, General Principles for Design

ISO 13849-1 Safety-Related Parts of Control Systems

ISO 13850 (EN 418) Emergency Stop Devices, Functional Aspects – Principles for Design

IEC 60204-1 Electrical Equipment of Machines Part 1: General Requirements

Contact: Global Engineering Documents, 15 Inverness Way East, Englewood, CO 80112-5704, Tel.: 800-854- 7179

Overview

An Emergency Stop Safety Module is used to increase the control reliability of an

emergency stop circuit. As shown in the hookup drawings, the models ES-

FA-9AA and ES-FA-11AA E-Stop Safety Modules are designed to monitor a 1-

channel or 2-channel E-stop switch. A 2-channel E-stop switch has two

electrically isolated contacts.

WARNING: Risk Assessment

The level of safety circuit integrity can be greatly affected

by the design and installation of the safety devices and the

means of interfacing of those devices. A risk assessment

must be performed to determine the appropriate level

of safety circuit integrity to ensure the expected risk

reduction is achieved and all relevant regulations and

standards are complied with.

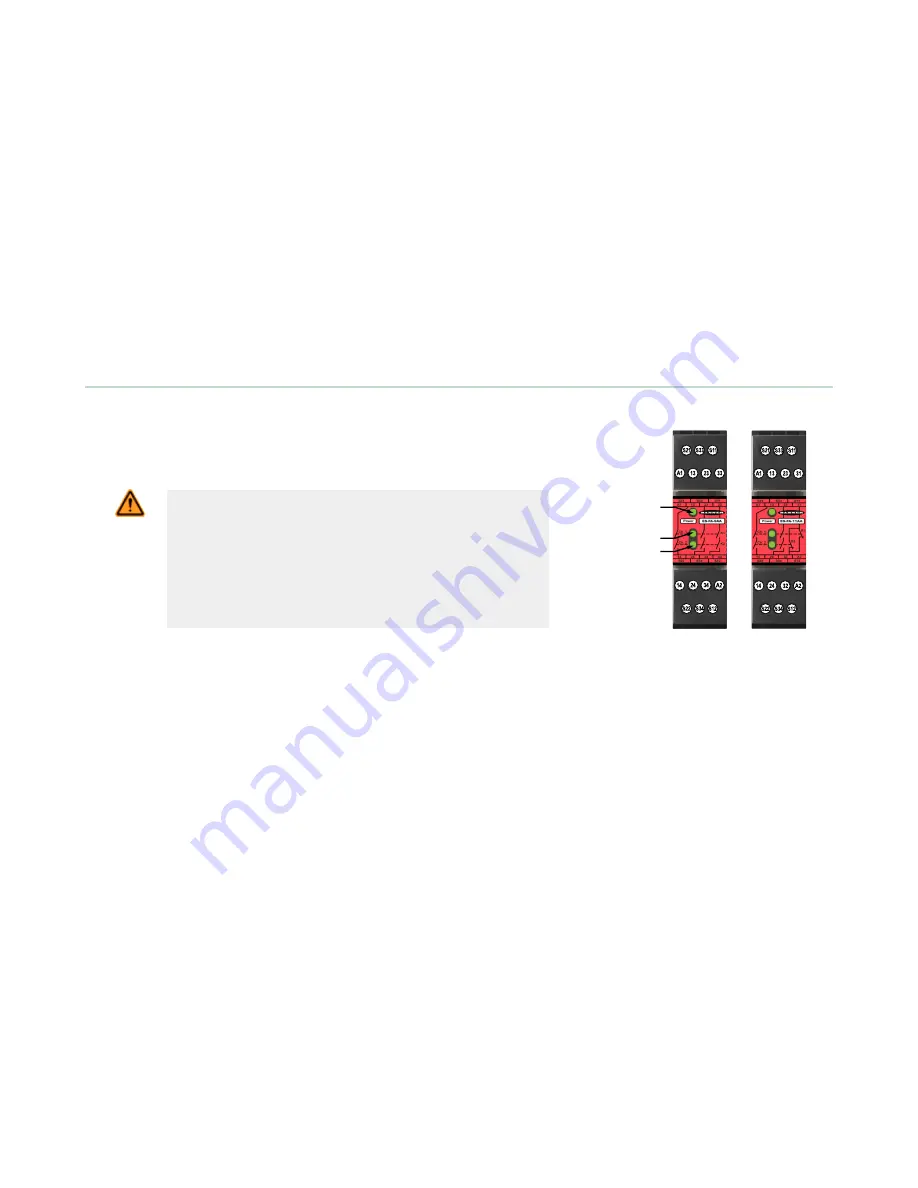

ES-FA-9AA

ES-FA-11AA

Power ON LED

Channel 1

Active LED

Channel 2

Active LED

Figure 1. Features and Terminals

Safety Circuit Integrity and ISO 13849-1 (EN954-1) Safety Circuit Principles

Safety circuits involve the safety-related functions of a machine that minimize the level of risk of harm. These safety-

related functions can prevent initiation, or they can stop or remove a hazard. The failure of a safety-related function or its

associated safety circuit usually results in an increased risk of harm.

The integrity of a safety circuit depends on several factors, including fault tolerance, risk reduction, reliable and well-tried

components, well-tried safety principles, and other design considerations.

Depending on the level of risk associated with the machine or its operation, an appropriate level of safety circuit integrity

(performance) must be incorporated into its design. Standards that detail safety performance levels include ANSI B11.19

Performance Criteria for Safeguarding and ISO 13849-1 Safety-Related Parts of a Control System.

Safety Circuit Integrity Levels

Safety circuits in International and European standards have been segmented into categories, depending on their ability to

maintain their integrity in the event of a failure. The most recognized standard that details safety circuit integrity levels is

ISO 13849-1 (EN954-1), which establishes five levels: Categories B, 1, 2, 3, and the most stringent, Category 4.

In the United States, the typical level of safety circuit integrity has been called ”control reliability.” Control reliability

typically incorporates redundant control and self-checking circuitry and has been loosely equated to ISO 13849-1

Categories 3 and 4 (see CSA Z432 and ANSI B11.TR4).

If the requirements described by ISO 13849-1 (EN954-1) are to be implemented, a risk assessment must first be

performed to determine the appropriate category, in order to ensure that the expected risk reduction is achieved. This risk

assessment must also take into account national regulations, such as U.S. control reliability or European “C” level

standards, to ensure that the minimum level of performance that has been mandated is complied with.

ES-FA-9AA and ES-FA-11AA E-Stop Safety Module

2

www.bannerengineering.com - Tel: +1-763-544-3164

P/N 60606 Rev. G