www.balluff.com

15

english

6

SSI interface (continued)

6.2

Data formats

Standard BTL7 has the following factory settings for

position output, which can no longer be changed

retroactively:

– SSI24, SSI25 or SSI26

– Binary or Gray coded

– Rising or falling

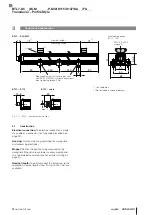

The contents of the information to be transferred and the

error value can be configured with the BTL7-S510(B)-….

Position, velocity, or differential position/velocity can be

sent via Data. The MSB is always transmitted first.

23

Position

0

M

L

Output of a position via SSI24

M = MSB (Most Significant Bit)

L = LSB (Least Significant Bit)

25 24 23 22 21 20

Error value or position value

0

0 0 0 0 1 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

Example of an SSI26 with an error bit in bit location 21 and

error value 0. The data length is 21 bits, the total bit number

is 26. Four zeros are transmitted before the error bit.

Clk

Data

15

1

2

3

4

5

SSI16

14

13

12

6

7

8

9

10

11

12

13

14

15

16

17

11

10

9

8

7

6

5

4

3

2

1

0

MSB

LSB

Fig. 6-1: Example of a complete SSI16 data transmission

Depending on the configuration, position or velocity data

may have a leading sign with the BTL7-S510(B)-….

Negative values are output as a two's complement. With

positive speeds, the magnet moves away from the

connection side; with negative speeds it moves towards

the connection side. The controller must be set to process

signed data then.

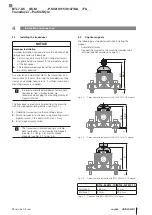

6.3

Faulty SSI query

Underclocking

If there are too few clock edges, the current data level will

be maintained for the time t

o

(t

o

= 2 · T

Clk

timeout times)

after the last negative edge from Clk. If, however, another

positive edge occurs, the next bit will then be output.

Afterwards, a T

o

event will occur internally, the data output

switches to low and then back to high after the time t

m

has

elapsed. The high level is maintained until the next clock

burst. Time t

m

starts after the end of time t

o

.

Overclocking

If there are too many clock edges, the data output will

switch to low after the correct number of cycles has been

completed. The t

m

timer is started again for every

additional negative edge from Clk and the T

m

event is set

internally. Data switches back to high after the time t

m

has

elapsed.

A T

o

or T

m

event is displayed in the status field as a

communication error in the Micropulse Configuration Tool.

In short, a communication error is caused by the following:

– The bit number set in the transducer does not

correspond to the bit number in the controller.

n

BTL

> n

PLC

→

T

o

event

n

BTL

< n

PLC

→

T

m

event

– The SSI clock frequency is too low

f

Clk

< 9.771 kHz

→

T

o

event

– The pause between two clock packages is too short

→

T

m

event

BTL7-S5_ _(B) -M _ _ _ _ -P-S32/S115/S147/KA_ _/FA_ _

Transducer – Profile Style

Summary of Contents for BTL7-S5-M Series

Page 1: ...Betriebsanleitung BTL7 S5_ _ B M_ _ _ _ P S32 S115 S147 KA_ _ FA_ _ deutsch...

Page 2: ...www balluff com...

Page 29: ...User s Guide BTL7 S5_ _ B M_ _ _ _ P S32 S115 S147 KA_ _ FA_ _ english...

Page 30: ...www balluff com...

Page 57: ...Manual de instrucciones BTL7 S5_ _ B M_ _ _ _ P S32 S115 S147 KA_ _ FA_ _ espa ol...

Page 58: ...www balluff com...

Page 85: ...Notice d utilisation BTL7 S5_ _ B M_ _ _ _ P S32 S115 S147 KA_ _ FA_ _ fran ais...

Page 86: ...www balluff com...

Page 113: ...Manuale d uso BTL7 S5_ _ B M_ _ _ _ P S32 S115 S147 KA_ _ FA_ _ italiano...

Page 114: ...www balluff com...