BTL5-T1_ _-M_ _ _ _-A/B/Y/Z-S103

Micropulse Linear Transducer - Rod Style

english

8

5

Configuration

➔

A

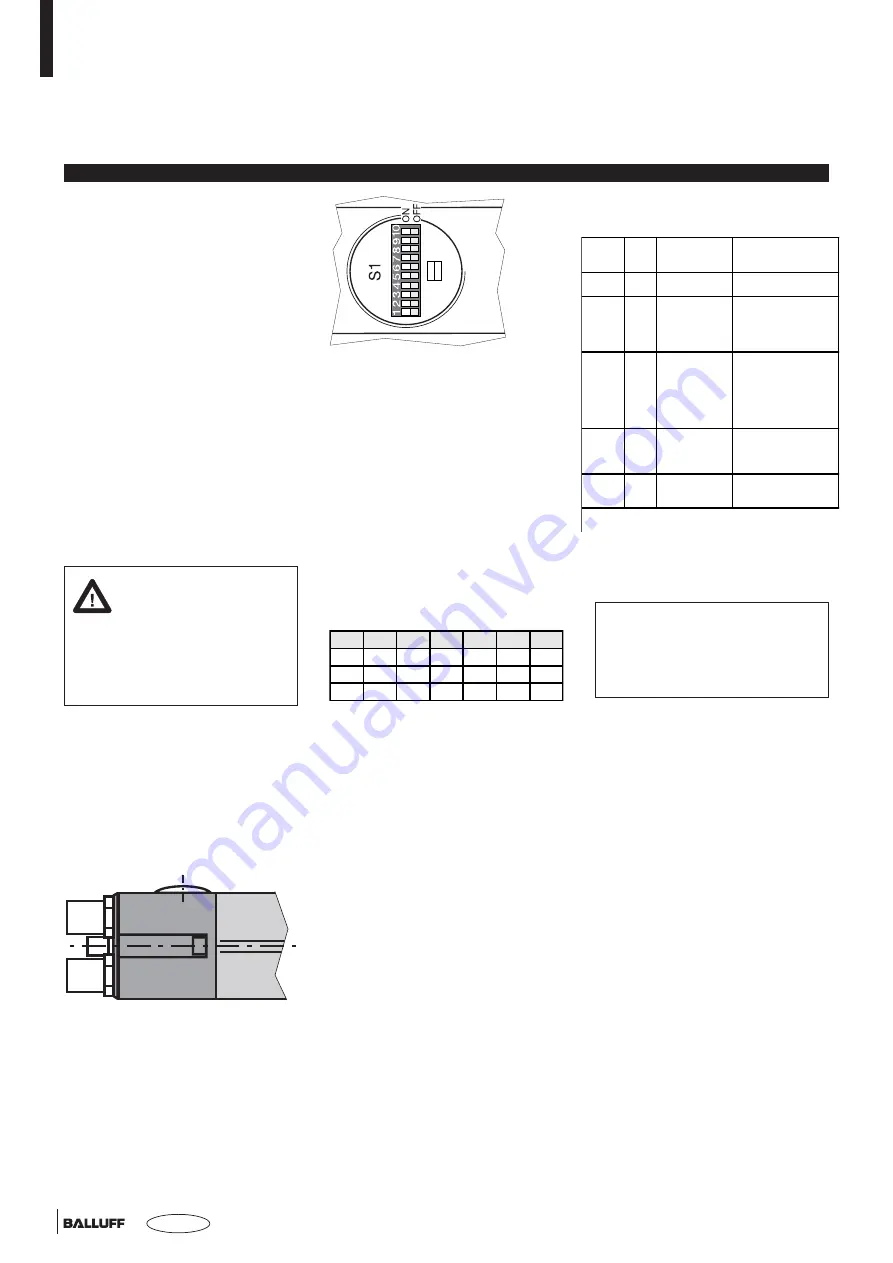

Fig. 5-1: Location of DIP switches S1

5.1

Default settings

The transducer is supplied with

the following default settings:

–

Station address

126

–

Resolution:

Position

5 µm

Velocity

0.1 mm/s

–

Maximum working/useful area

5.2

Presets

The service Set_Slave_Address

can be used to configure the sta-

tion address. For this service you

need a DP Master Class 2. The

GSD file BTL504B2.GSD (trans-

ducer system) is used for configu-

ration. The GSD file provides all

the information required for set-

tings. For configuring, the Siemens

COM PROFIBUS can be used for

example.

When opening the BTL

housing make sure no

parts get into the device.

When closing up the cover en-

sure the gasket is sufficiently

compressed. Tightening torque:

1.5 Nm

For use in standard PROFIBUS

systems the station address and

the termination resistor are set

before startup using the DIP

switch S1 which is built into the

BTL (

➥

➥

➥

➥

➥

Figs. 5-1 and 5-2).

5.2.1 Station address

Values from 0 - 125 can be used

for the station address. In a net-

work each address can be used

only oince! For value 126 the ad-

dress 126 or the last address set

using the Set_Slave_Address ser-

vice is used. A value of 127 resets

the BTL to its default condition.

Since 127 does not represent a

valid address, bus operation is

then not allowed.

S1.1 S1.2 S1.3 S1.4 S1.5 S1.6 S1.7

2

0

2

1

2

2

2

3

2

4

2

5

2

6

LSB

MSB

1

2

4

8

16

32

64

All address settings only become

effective after a power reset.

Changes which are made while

power is on do not therefore have

an immediate effect.

5.2.2 Bus termination

To ensure a reliable rest signal

level the bus must be appropri-

ately terminated on both ends as

shown in Fig. 4-2. The BTL5-T al-

lows the bus to be terminated in-

ternally. To do this set DIP

switches S1.9 and S1.10 to ON,

➥

➥

➥

➥

➥

Fig. 5-2. For IP 67 the bus ter-

mination resistor suggested in Fig.

4-6 must be used. Then the inter-

nal bus termination should not be

activated (S1.9 and S1.10 OFF)!

Stub lines should be avoided

whenever possible.

5.2.3 LED Display PROFIBUS

Encoder Profile

If multiple faults are present at the

same time, the fault with the high-

est priority is displayed.

A detailed configuration guide can

be obtained on the Internet at

www.balluff.com\downloads-btl5

or via e-mail to

[email protected]

Fig. 5-2: View A, DIP switches S1

for setting station address and for

bus termination

LED

red

(BF)

1

LED

green

Meaning

Cause

Off

Off

No supply

voltage

On

On

No connection to

another station

(no

Data_Exchange)

- Bus not connected

- Master not

available/turned off

On

Flash-

ing

2

Parameterizing

error, no

Data_Exchange

- Slave is not/incorrectly

configured

- Wrong station address

assigned (within the

permissible range)

- Wrong PRM or CFG

telegram received

Flashing

2

Flash-

ing

2

Position error

- No magnet in the valid

measuring range or

number of magnets

incorrect

Off

On

Data_Exchange

Slave and

function OK

- BTL working,

everything OK

1

BF = Bus fault

2

Flash rate 0.5 Hz

green

red