www.baldormotion.com

4-6 Input / Output

MN1901

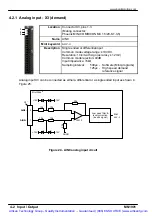

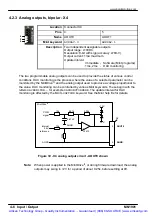

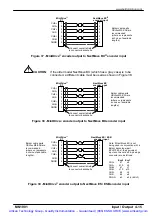

4.2.3 Analog outputs, bipolar - X4

Location

Connector X4

Pins

4

5

Name

AOUT0

AOUT1

Mint keyword

AUXDAC.0

AUXDAC.1

Description

Two independent assignable outputs.

Output range: ±10VDC.

Resolution: 8-bit with sign (accuracy ±78mV).

Output current: 1mA maximum.

Update interval:

Immediate - Software (Mint programs)

1ms, 2ms - DAC monitoring

The two programmable analog outputs can be used to provide the status of various control

conditions. DAC monitoring is the process where the value of a selected parameter can be

monitored by the MintDrive

II

, and the analog output used to produce a voltage proportional to

the value. DAC monitoring can be controlled by various Mint keywords. These begin with the

letters

DACMONITOR

..., for example

DACMONITORMODE

. The update interval for DAC

monitoring is affected by the Mint

LOOPTIME

keyword. See the Mint help file for details.

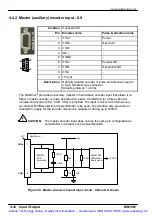

10k

LF412

AGND

MintDrive

II

68.1k

75k

-15V

+15V

300k

-

+

300k

0.47nF

Internal

2.5V

reference

AGND

PWM

signal

AOUT0

AGND

4

6

‘X4’

Figure 30 - X4 analog output circuit - AOUT0 shown

Note:

When power is applied to the MintDrive

II

, or during firmware download, the analog

outputs may swing to +2V for a period of about 0.25s, before settling at 0V.

4

5

6

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com