1. Insert the pump in a vice in a horizontal posi-

tion, grasp it by the suction tube.

2.

Unscrew the intake filter tube (42) from the

intake filter head (39) (fig. 1).

3. Unscrew the air motor body from the suction

tube using a threaded rod (fig. 2), and pull it out

until it stops. The union nut should be visible.

4. Introduce an open end wrench in the milling

of the lower part of the air piston and unscrew

the nut (41) and remove the washer (40) (fig. 3).

5. Remove the pin (25) situated in the upper

part of the union nut (fig. 4) and unscrew the air

motor body from the suction tube assembly.

7

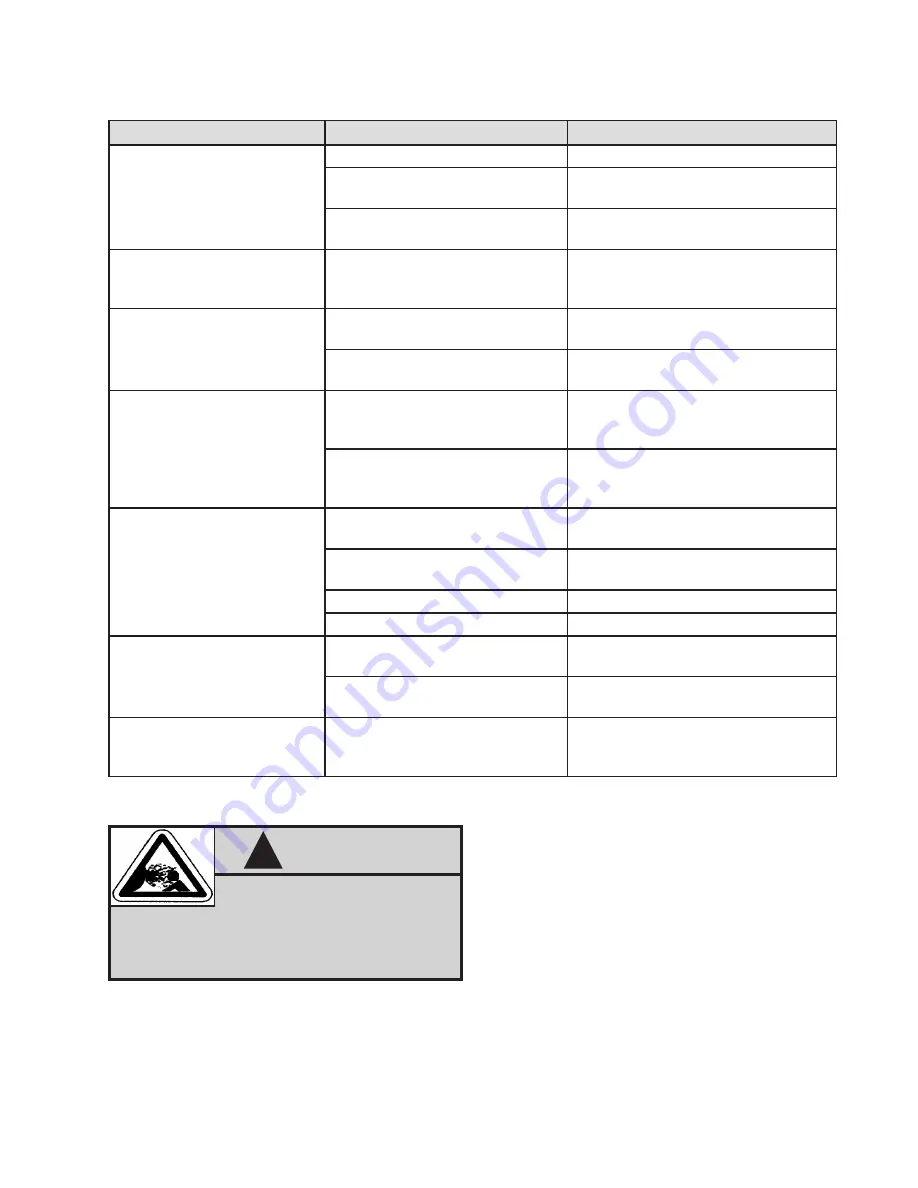

TROUBLESHOOTING

Symptom

Possible Cause

Solution

The pump is not working or

there is no grease delivery.

Not enough air supply pressure.

Increase the air supply pressure.

An outlet line component is

clogged or closed.

Clean or open the outlet circuit.

There are air pockets in the

grease inlet area.

Compact the grease.

The pump begins to operate

very fast.

The drum is empty or the grease

level is beneath the suction tube

inlet.

Replace the drum or lower the suction

tube until the inlet reaches the grease

level.

The pump keeps on operating

although the grease outlet is

closed.

There is a grease leakage in some

point of the outlet circuit.

Verify and tighten or repair.

Impurities in the upper valve or in

the foot valve.

Remove and clean. Replace in case of

damage.

Grease leakage through the

air outlet muffler.

Grease has by-passed to the air

motor caused by worn or dam-

aged seals (22, 23) or O-ring (21).

Replace the worn or damaged parts.

The suction tube is not tightened

enough to the motor body.

Tighten the threaded union. Verify that

the O-ring (21) is in its correct posi-

tion.

Air leakage through the air

outlet muffler.

The sliding valve (12) does not

close correctly.

Remove and clean. Replace in case of

damage.

The valve support (13) or the

spring (19) are damaged.

Replace the items.

The air piston (3) is damaged.

Replace it.

The O-ring (5) is damaged.

Replace the Gland housing assembly.

Reduction in grease delivery.

There are air pockets in the

grease inlet area.

Compact the grease.

Impurities in the upper valve or in

the foot valve.

Remove and clean. Replace in case of

damage.

Reduction in grease pressure. The high pressure cylinder (33)

or the high pressure piston (29)

scratched.

Replace the items.

MAINTENANCE

WARNING

!

Before starting any kind of

maintenance or repair, Follow the pressure

relief procedure on page 2 of this service

bulletin.

Foot valve kit