8 | Baker Hughes

Copyright 2021 Baker Hughes Company. All rights reserved.

Gaskets

Gasket seating surfaces must be free of dents, scratches,

corrosion, or other types of damage. Clean mating surfaces as

required and replace any non-conforming parts. Spiral wound

gaskets (Items 25, 26 & 27) must always be replaced after

disassembly.

Seal Rings

Seal rings (9), back-up rings (28), retaining rings (23), and

conical springs (14) should be inspected periodically. It is

recommended to routinely replace these parts, but they may

be re-used if they are free from scratches, erosion, corrosion,

or other damage.

Note: Compressed graphite seal rings must be replaced

each time the plug is removed from the valve.

Metal Seal

For the two piece bonnet configurations:

Prior to reassembly, the metal seal (6) should be inspected for

cracks or signs of wear. The metal seal can be reused if it is

free from scratches, erosion, corrosion, or any other type of

damage.

If slight wear exists on the metal seal, a new layer of coating

should be re-applied to the original condition by the factory

or a Masoneilan Authorized Repair Center (

MARC

™

). For

emergency repairs in the field, the metal seal may be coated

with a molybdenum disulfide based spray on lubricant such as

MolyKote

®

.

Prior to reassembly of the valve, inspect the inside of the valve

body around the area where the metal seal seats. It is common

to find slight ridges or depressions from where the seal was

originally seated. During initial assembly these depressions aid

in the sealing of the valve, however these areas can become

leak paths during reassembly if the surface is not restored to its

original finish as described below.

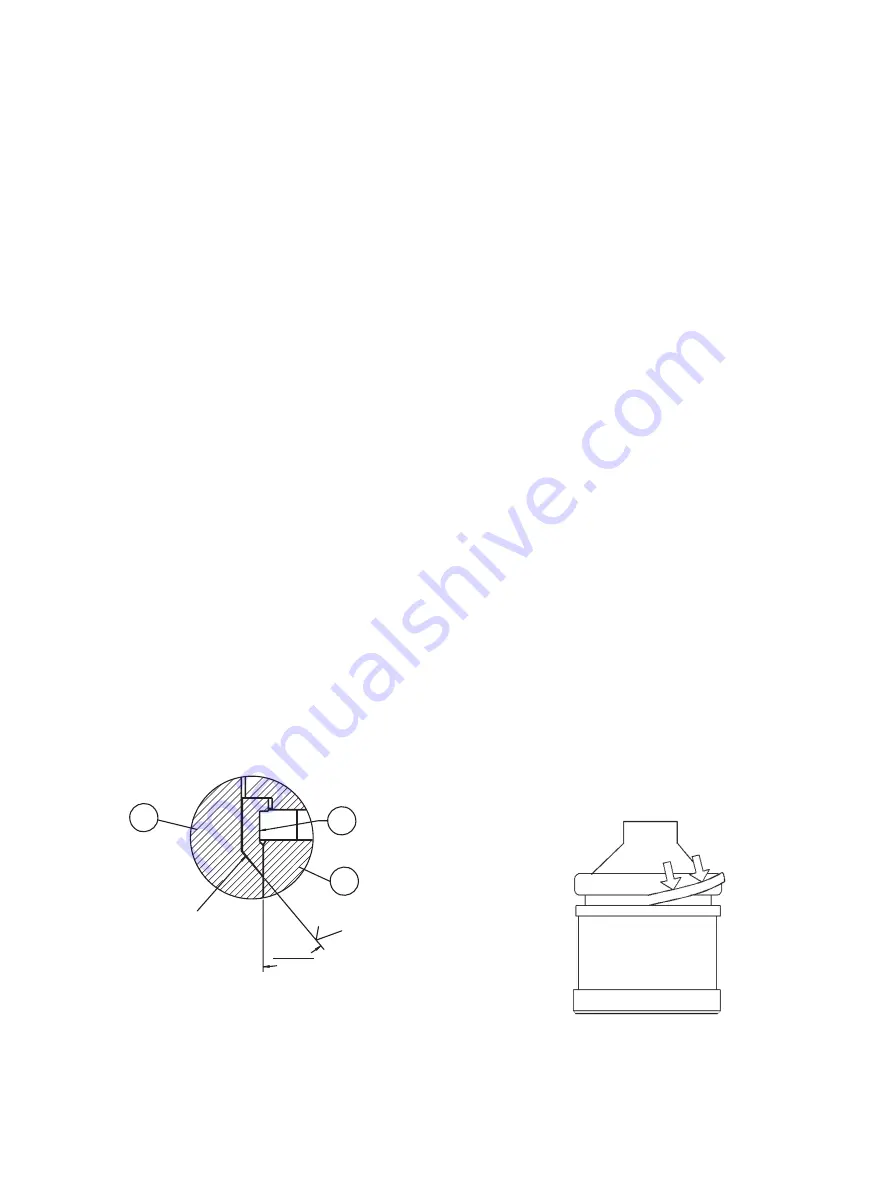

To prevent this potential leakage, machine the seating angle of

the bonnet at 40 degrees by approximately 0.1 inches (2.5 mm)

deep, thus causing the metal seal to seat further down inside

the valve body (on a new undeformed surface). Refer to Figure

7 for details.

Figure 7 - Bonnet Seating Angle Details

(see page 12, detail B)

Figure 8 - Installing Seal Ring

Conical Springs

For Models that use a conical spring design, always inspect the

body bore surface adjacent to where the conical spring (14) is

seated. If this surface has been deformed or if there is a groove

where the seal seats, the surface should be cleaned and honed

prior to reassembling the valve.

If the refinishing procedure is unsuccessful, the factory should

be consulted for further instructions.

Valve Reassembly

Pinning the Valve Plug

The valve plug assembly consists of a stem (7) that is threaded

into the valve plug (8). To secure this assembly, the stem (7) is

then pinned (24) and tack welded to the valve plug (8).

If the valve plug (8) or stem (7) needs to be replaced, an entire

assembly should be purchased from the factory to ensure

product strength and integrity. Re-machining of these parts

in the field can seriously impair the mechanical strength and

integrity of the valve plug stem assembly.

Seal Ring Assembly

Model 724XX (Auxiliary Pilot Plug) and

725XX (Metal Seal Ring)

1. To insert the seal ring in the valve plug groove, place it over

the conical top of the plug, then push down evenly from all

sides until the ring slips into the groove. See Figure 8.

Note: These valves may also be equipped with a second-

ary metal seal and elastomeric back-up ring located on the

lower area of the plug near the seating surface.

2. Install the back-up ring (28) onto the plug using care not

to damage the ring on any sharp surfaces. The back-up

ring does not require lubrication, however, a light coating of

compatible lubricant will help install the seal.

3. Install the seal ring (9) over the back-up ring (28).

Note: When the plug assembly is installed into the cage

bore, the lead in angle of the cage will compress the ring

into place. If the seal ring is not compressed a ring com-

pression tool may be required for proper installation.

6

AND BURRS

EDGE MUST BE

FREE FROM NICKS

Ra

0.8

40°30'

39°30'

2

1

Pushing

Direction