6 | Baker Hughes

Copyright 2021 Baker Hughes Company. All rights reserved.

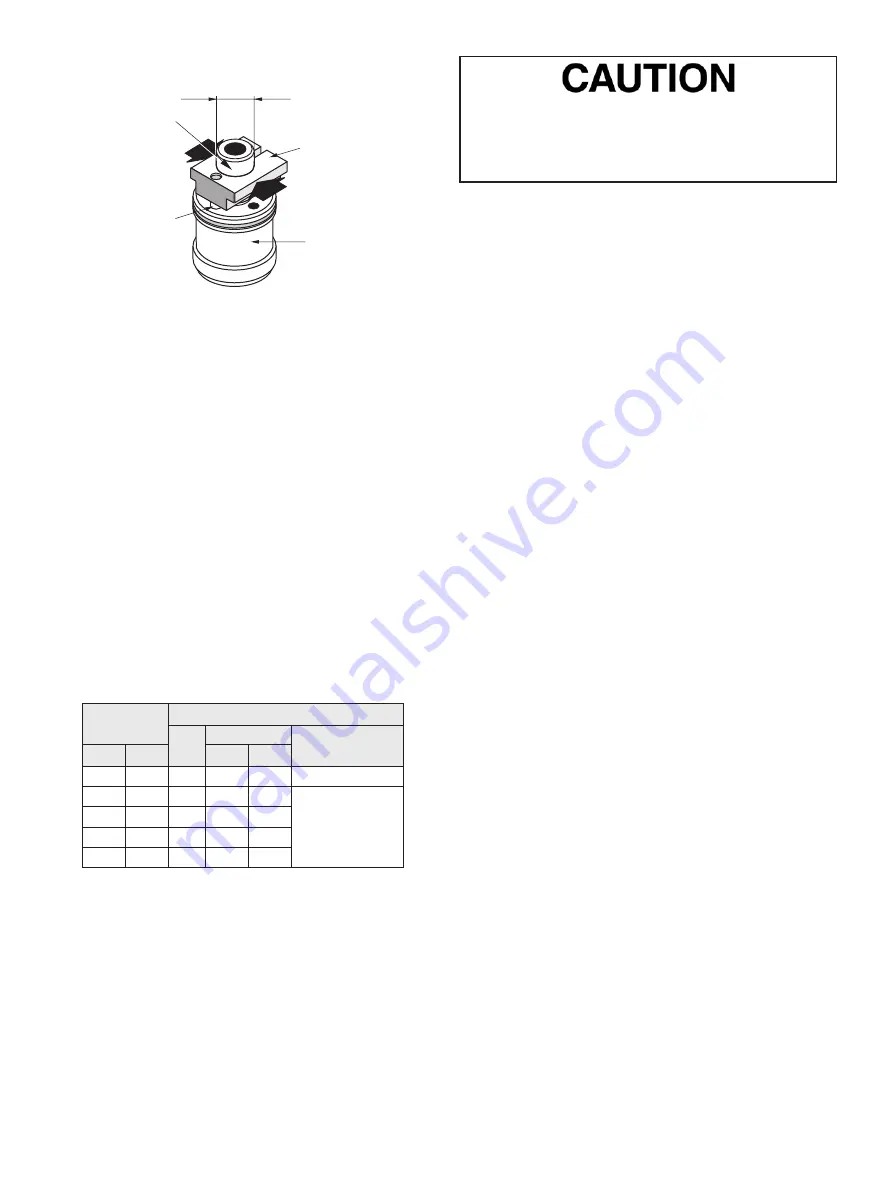

Tight only

on this

non-guiding

surface

Do not

tighten

on the

plug skirt

Soft metal

vise jaw

Cylindrical machining

diameter of the jaw =

plug shank diameter:

Dia. A

Stop pin

integrated in

vise jaw and

inserted into a

plug hole

Figure 4 - Valve Plug Stem S/A Disassembly

Auxiliary Pilot Plug Disassembly

(Model 724XX)

For size 3" or 4" (80 or 100 mm) valves:

Exert a sufficient force on the auxiliary pilot plug (21) to

compress the pilot springs (22). The retaining ring (23) can then

be removed, allowing for disassembly of the auxiliary pilot plug

and springs.

Some auxiliary pilot plug designs may incorporate a threaded

and welded retaining ring. For disassembly machine removal of

the weld is required. After removal of the weld, compress the

pilot assembly to unthread the retainer.

For size 6" to 16" (150 to 400 mm) plug sizes:

To carry out this operation safely, screws with diameters and

lengths indicated in Table 1 must be used. Thread the socket

head cap screws through the holes in the auxiliary pilot plug

(21). Tighten until the retaining ring (23) can be removed.

Loosen the screws gradually, then remove the auxiliary pilot

plug and the spring (22).

Maintenance and Repair

The purpose of this section is to provide recommended

maintenance and repair procedures. These procedures assume

the availability of standard shop tools and equipment.

Packing Box

Tight sealing within the packing box is obtained by compression

of the packing (19). Compression must be achieved by evenly

tightening the packing flange nuts (16) on the packing flange

(17). Periodic re-tightening of the packing flange nuts may be

required to maintain proper sealing.

Be careful not to over tighten the packing as this

could prevent proper operation of the valve. If leakage

persists after maximum packing compression, then

the packing needs to be changed.

Table 1

Valve Size.

Pilot Dismounting Screw Sizes

Qty

Length

Diameter

in.

mm

in.

mm

6

150

2

2.25

57.0

1/4"- 20 UNC 2A

8

20

2

2.5

63.5

3/8"- 16 UNC 2A

10

250

2

2.75

70.0

12

300

3

4.00

101.5

16

400

3

4.00

101.5

PTFE Packing and

PTFE V-Ring Packing

Kevlar

®

/PTFE, carbon/PTFE and pure PTFE packing rings are

cut in such a way that they can be replaced without having to

separate the valve plug stem from the actuator stem.

Note: V-Ring packing requires smooth, 32 µ inch RMS or

finer, finish. Inspect stem and packing box bore to ensure

the surfaces have not been damaged. If damage has

occurred, the surfaces must be repaired to ensure proper

sealing.

1. Unscrew and remove the packing flange nuts (16).

2. Lift the packing flange (17) and packing follower (18) up

along the valve stem (7).

3. By means of a puller, remove the packing (19) being careful

not to damage the sealing surface of the packing box or the

valve plug stem.

4. Replace the packing rings, placing the cut in each ring

about 120° apart from the adjacent ring. Press rings in one

at a time.

5. Reassemble the packing follower (18) and the packing

flange (17).

6. Tighten the packing flange nuts (16) without over

compressing the packing rings.

Note: In case of V-ring packing, compress packing flange

nuts to finger tight, plus one half additional turn.

7. Put the valve back into service and check for leakage. If

packing leaks, tighten packing flange nuts (16) in half turn

increments as required.

Valve with Graphite Packing

To replace graphite packing, it is necessary to separate the

valve plug stem from the actuator stem.

1. Remove the packing flange nuts (16) from the packing

flange studs (15).

2. Lift the packing flange (17) and packing follower (18) up

along the valve stem (7).

3. By means of a puller, remove the packing (19) being careful

not to damage the sealing surface of the packing box or the

valve plug stem.

4. Replace the packing (19). Press a back-up ring (car-bon/

graphite/Inconel braided ring) into the bonnet (2). Next

press the expanded graphite rings into the packing area

one at a time. Press an additional back-up ring into packing

area.

5. Reassemble the packing follower (18) and the packing

flange (17).

6. Tighten the packing flange nuts (16) without over-

compressing the packing rings.