24 |

Baker Hughes

© 2020 Baker Hughes Company. All rights reserved.

XIV. Setting and Testing (Cont.)

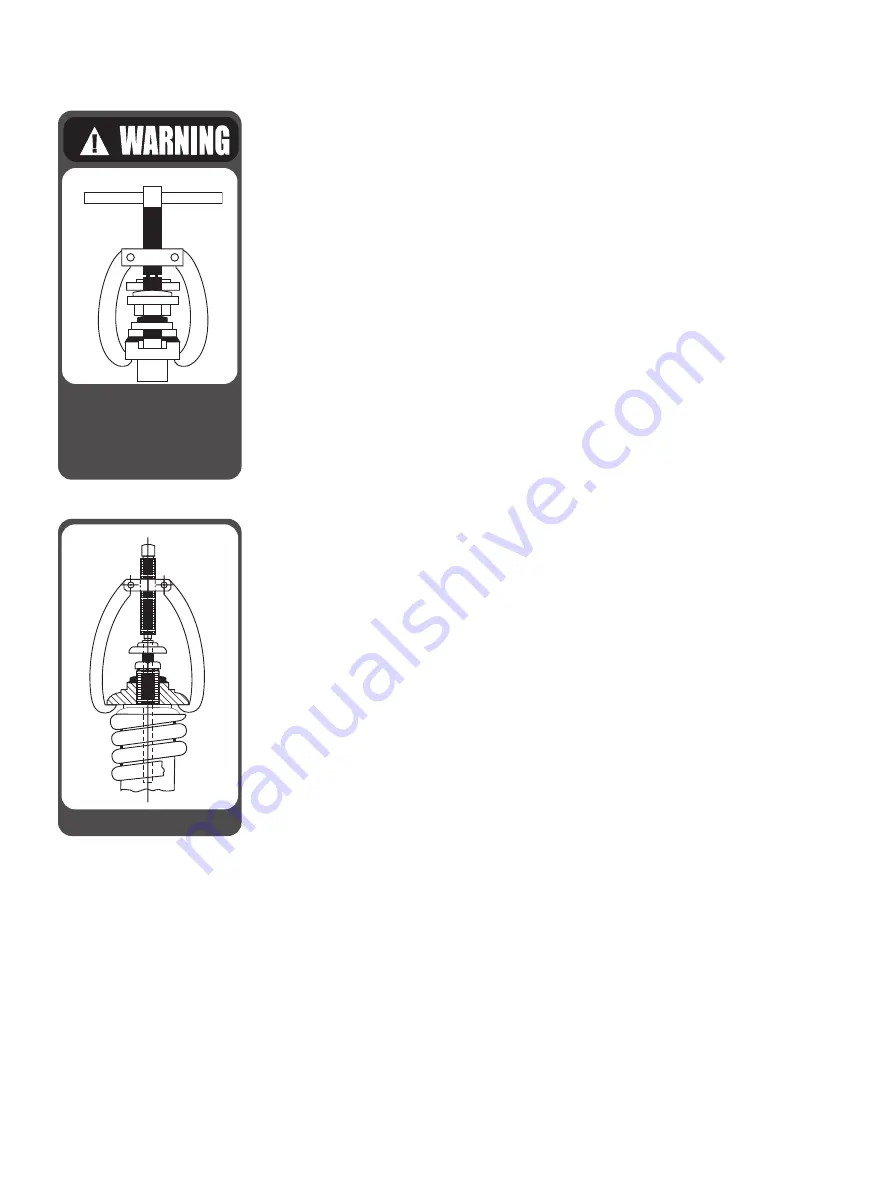

Figure 14

Gag safety valve during

ring adjustments to

avoid possible severe

personal injury or

death.

pressure of the safety valve, it is

recommended the valve be replaced

with a blind flange during hydrostatic

testing.

Probably the most common source of

safety valve trouble is overgagging.

During hydrostatic testing, and during

safety valve setting, gags should be

applied only hand tight. During setting,

overgagging could cause damage

to the seating surface and result in

leakage. In applying gags, remember

that the valve spring will hold the valve

closed against its set pressure. The

additional gag load applied should

be only enough to insure that the

valves do not lift at the expected over-

pressure.

Gags should never be applied when

the boiler is cold. The spindle of the

safety valve expands considerably with

the temperature increase as pressure

is raised. If it is not free to expand with

this temperature change, the spindle

may be damaged.

Boiler pressure should be increased

to 80% of the pressure of the low set

valve before applying the gags.

Hand tighten the gags of drum and

superheater valves with only a light

force.

B.2 Application of Test

Gags (All Pressures)

1. Refer to Figures 1 & 2 on Section

VIII. Remove lever pin and lever.

Then loosen cap screw and remove

cap.

2. Center the test gag screw in the

exposed end of the spindle and

hook the legs of gag under the

sides of the yoke as shown in

Figure 14.

Do not apply the gag load until

the boiler hydrostatic pressure

is equal to 80% of the pressure

to which the low set valve is

adjusted.

3. Apply the gag load by turning the

gag screw clockwise. If the gag on

any valve has not been tightened

sufficiently, the valve will leak.

If this occurs, the hydrostatic

test pressure should be reduced

until the valve becomes tight and

then the gag should be tightened

still further.

This procedure must be followed

exactly since it is very difficult to

stop the leak by additional gagging

once it has started. Any attempt

to pinch off the leakage through

the valve without first lowering the

hydrostatic pressure may result in

damage to the valve seats.

4. After the hydrostatic test is

completed, the gags should be

removed when the hydrostatic

pressure has been reduced to 85%

to 90% of the low set valve.

Under no circumstances should

the gags be left on valves with

no hydrostatic pressure on the

system.

C. Presetting the

Adjusting Rings

If the correct position of the adjusting

rings (as measured in the disassembly

procedure (see Section X) is not

known, the valve adjusting rings may

be positioned using the information in

Table 9.

The lower ring may be positioned by

turning the lower adjusting ring up until

it contacts the disc. After choosing

the appropriate orifice size, turn the

adjusting ring down the corresponding

number of notches listed in the “Lower

Ring” column. Then, replace the

adjusting ring pin. The adjusting ring

must be free to move both directions,

but not rotate.

The upper ring may be positioned by

turning the upper adjusting ring down

towards the nozzle bushing, until it