29

29

OPERATION

1. Place the work piece on the table so that it is aligned with the piston rod. If this is not

possible, reposition the cylinder to achieve the best alignment.

2. Take care when performing operation on elements that are likely to fly off, break (especially

casting element and hardened elements) or bounce up as a result of the applied force. In

this case, a cover must be installed around the work piece or the operator should stand at a

safe distance.

3. After correct placement of the work piece, pressing force can be applied using the directional

valve or the hand pump as described in the previous section.

Note:

Upwards movement of the piston is only allowed for adjustment of the table,

or returning the piston to its start position. Any other use of the return stroke (e.g. stretching) can

result in broken parts and de-function of the press.

When pressing operations are finished:

4. Return the piston back to its upper position.

5. Position the cylinder back it the center of the machine.

6. Turn of the hydraulic unit.

7. Clean up the machine and working area.

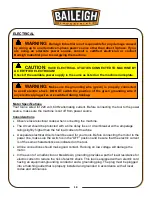

CAUTION:

Always wear proper eye protection with side shields, safety

footwear, and leather gloves to protect from burrs and sharp edges.

WARNING:

Failure to center the piece part on the blocks and the ram to

the piece part may cause serious injury.

Never compress springs or objects that when compressed, could shatter, or explode

out of the press causing serious injury.

Summary of Contents for HSP-176M-HD

Page 3: ...ELECTRICAL SCHEMATIC 38 Electrical Parts List 38 TROUBLESHOOTING 39 ...

Page 19: ...16 16 GETTING TO KNOW YOUR MACHINE A I G H L J B F K C E D ...

Page 30: ...27 27 Using the Machine Incorrect Correct ...

Page 31: ...28 28 Incorrect Correct ...

Page 37: ...34 34 RAM PARTS DIAGRAM ...

Page 39: ...36 36 HYDRAULIC PUMP PARTS DIAGRAM ...

Page 43: ...40 40 NOTES ...