BA_1

11_00_DEF_MJ_0419

5 |

23

W. Baelz & Sohn GmbH & Co.

· Koepffstrasse 5 · 74076 Heilbronn · Germany ·

www.baelz.de Seite | Page

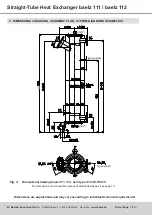

Straight-Tube Heat Exchanger baelz 111 / baelz 112

1.3 Personnel

Only qualified personnel may work on this heat exchanger or in its vicinity. Qualified persons are deemed to be

persons who are familiar with the installation, assembly, commissioning and operation or maintenance of the heat

exchangers and have the appropriate qualifications for their job. Necessary or prescribed qualifications include,

but are not limited to:

● Safety-relevant instruction or training in this field and obligation to comply with regional and internal

safety technology standards.

●

Training or instruction in the care and use of appropriate safety and work protection equipment

in accordance with safety technology standards.

●

First aid training.

Work in a safe manner and avoid any operation that would endanger the safety of persons or damage the heat

transfer station or other property in any way.

1.4 Before starting work

Before carrying out any work, check whether the types specified here correspond to the information on the name

plate of the heat exchanger:

baelz 111 / baelz 112

1.5 During operation

Safe operation is only possible if transport, storage, assembly, operation and maintenance is carried out in a safe,

proper and professional manner.

1.5.1 Transport, installation and assembly

Observe the general installation and safety regulations for heating, ventilation, air conditioning and piping

systems. Use tools only for their intended purpose. Wear the required personal and other protective equipment.

1.5.2 Maintenance and repair

Ensure that qualified personnel take the heat exchanger out of operation before carrying out maintenance or

repair work. As a rule, work must only be carried out on heat exchangers when they are not under pressure.

For maintenance and cleaning procedures, see chapter 6.

Immediately after completion of maintenance work, all safety and protective devices must be refitted or put into

operation.

For the recommissioning procedure, see chapter 5.

1.5.3 Hazard prevention

Components of the heat exchanger which may become hot or cold must be protected against contact. Use

warning signs to indicate possible dangers, e.g. caused by hot or cold surfaces or operating errors.

1.6 Working environment

Note the specifications for the working environment in the technical data.