BA_1

11_00_DEF_MJ_0419

15 |

23

W. Baelz & Sohn GmbH & Co.

· Koepffstrasse 5 · 74076 Heilbronn · Germany ·

www.baelz.de Seite | Page

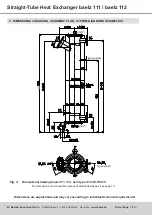

Straight-Tube Heat Exchanger baelz 111 / baelz 112

●

Removable head covers enable both ends of each tube to be inspected and repaired. In the case of

leaking tube connections, it may suffice to rework the tube sheet connection with a special mandrel.

However, it is more practical to drive in a guide bushing or a plug.

●

Pipe openings can be sealed by shutting down the affected heating pipe using blind plugs.

Take care when tightening the flange couplings! Observe the following remarks.

Beware

● Tighten the flange screws crosswise and particularly evenly. Too forceful and uneven retightening distorts

the flanges and leads to permanent leakage. Tightening too tightly can also cause the seals to flow.

Always observe the permissible surface pressure of the seals. Use a torque wrench and ensure that the

thread runs smoothly by applying heat-resistant lubricant on clean screws. Please refer to the Baelz data

sheet DS 80900...81100 for tightening torques depending on screw size and material.

7. DECOMMISSIONING AND DISPOSAL

Hot surfaces when insulation is removed! Risk of burns if touched!

Danger

7.1 Decommissioning

● When decommissioning, first shut off the heating medium.

●

Shut down the ancillary equipment according to the relevant documentation.

●

Empty the heat exchanger completely.

●

Let the heat exchanger dry out as completely as possible to avoid standing liquids.

7.2 Disposal

●

Dispose of or recycle the heat exchanger in accordance with national regulations.

●

Do not dispose of lubricants and hazardous substances in household waste.