Scope of this manual

Page 5

April 2017

CTL-UM-01028-EN-03

SCOPE OF THIS MANUAL

The sections in this manual have been arranged in such a way that you can, step by step, install, program, operate and when

required, troubleshoot the instrument

MPOOTANT

I

Read this manual carefully before attempting any installation or operation.

Keep the manual in an accessible location for future reference.

Safety Terminology and Symbols

Indicates a hazardous situation, which, if not avoided, is estimated to be capable of causing death or serious personal injury

Indicates a hazardous situation, which, if not avoided, could result in severe personal injury or death

Indicates a hazardous situation, which, if not avoided, is estimated to be capable of causing minor or moderate personal

injury or damage to property

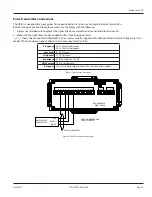

CB-30 BATCH CONTOOLLEO DESCOIPTION

The CB-30 is a batch controller that accepts a signal input from the meter transmitter, scales it to the desired unit of measure

and—at a preset point(s)—sends a signal to operate the flow valve

Other features include: automatic compensation for valve overrun, batch size limit, fail-safe shutdown, and manual batching

UNPACKING, ASSEMBLING AND INSTALLING THE CB-30

Unpacking the CB-30

OTEE:

N

If damage to the shipping container is obvious, request that the carrier be present when the product is unpacked All

claims for equipment damage during transit are the sole responsibility of the recipient

After carefully unpacking the unit, check for any visible sign of damage If found, notify the carrier for insurance purposes and

call the factory for possible replacement Keep all packing material in the event that the unit must be returned to the factory

OTEE:

N

Operating temperature is 32…130° F (0…55° C) with a maximum humidity of 85% non condensing Always select a

mounting location with proper ventilation and environmental protection

5.63 in.

(138 mm)

2.64 in.

(67 mm)

Panel Cutout

2.83” (72 mm)

5.67” (144 mm)

Figure 1: Panel Cutout and Mounting Dimensions