Understanding the batch cycle

Page 15

April 2017

CTL-UM-01028-EN-03

MPOOTANT

I

The CB-30 is programmed at the factory with a pulse fail-safe period of three seconds. This means that if a transmitter pulse is not

received within three seconds of a START command or the last pulse, (in the middle of the batch) the valve will close and the display

to the left will start blinking. After correcting the problem (bad transmitter, valve or pump) press

RESET

to start over.

Determining the Compensation Value

When a slow closing valve is used, (to prevent water hammer) the CB-30 can be programmed to begin closing the valve ahead

of time to compensate for the water overrun during the closing period

To determine the amount of overrun, run one or two batches with the CB-30 without a compensation value and without a

wash value

1 Preset a typical batch (250 gallons)

2 Press

STAOT

and let the batch run

The counter will count down to zero, and if there is an overrun, the counter will display the amount as a negative number

(for example, –5 This is the number that must be programmed to compensate for valve overrun

3 To program, press

COMP

, enter

5

, then press

ENTEO

The CB-30 will begin closing the valve 5 gallons prior to the Batch and Wash preset values that are programmed On the

second test batch, the counter may actually stop short of zero (for example, at 1) This indicates that the compensation value

must be changed from 5 to 4 gallons

Determining the Scale Factor

The scale factor is a number that multiplies the incoming pulses from the flow meter It converts them to desired units of

measure such as US gallons, liters, imperial gallons or pounds

To determine the appropriate factor for the type and model of flow meter in use, apply the following formula:

1 gallon (liters, etc )

=

Scale Factor

Pulse rate (liters, etc )

Example: For a 3" Turbo, the pulse input coming from

the PFR-3E transmitter is 24 8 pulses per gallon

Therefore:

1 gallon

=

0.0403

24 8 pulses per gallon

To set the scale factor:

1 Press

SCALE

2 Enter

0403

3 Press

ENTEO

The scale factor will appear as follows:

0

in the left display and

403

on the right display

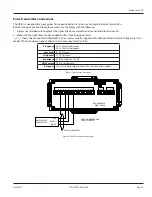

Turbo

Size

Pulses per

Gal

Scale Factors

PFT-3E

2"

34 72

0 0288

3"

24 80

0 0403

4"

5 12

0 1953

6"

2 16

0 4629

Table 9: Scale Factor