INSTALLATION AND MAINTENANCE INSTRUCTIONS - ORIGINAL VERSION

AVK GATE- AND SERVICE CONNECTION VALVES FOR GAS

SERIES 02, 03, 06, 36, 38 and 46

Parallel alignment of flanges is especially important in the case of the assembly of a valve into an existing system.

The bolting used for the flange connection must be checked for correct size, length, material and that all connection flange bolt

holes are utilised. See table 1 for bolt sizes.

If a permanent extension spindle and road cover is used only a permanent telescopic extension spindle that is not completely

collapsed (shall be extracted e.g. min. 50 mm) shall be used to avoid transfer any loads to the buried valve.

Gate valves with spigot pipe ends are to be installed either by means of appropriate welding or the use of a suitable coupling.

For welding procedures please refer to pipe manufacturers’ specifications.

For choice of coupling please consult an AVK representative.

Special care shall be taken when installing gate valves with purge points. The purge point pipes shall be protected from any

sideway loads, both during handling and after installation.

13. OPERATION

Gate valves are typically operated with an extension spindle in below ground installations. In manholes or in above ground

installations handwheels or electric actuators may be used. Ensure proper sizing of the handwheel and/or operating keys,

extension spindles and actuators. Please refer to AVK datasheets for further information. When installing gate valves mounted

with electric actuators, please observe closing torques and number of turns from the datasheet. When the valve is installed

in a chamber with an extension spindle going to above ground level, ensure that no vertical force from the extension spindle

presses down directly on the valve stem top. The extension spindle must be supported by wall mounts or similar to prevent

vertical forces and thereby supporting the weight of the extension spindle.

When closing the gate valve ensure that the appropriate torque and number of turns are applied to the valve. See table 2.

14. PRESSURE TESTING

After installation, perform a pressure test before the trench is closed. Secure the pipe and gate valve against movement. If the

pipeline and valve are tested with water prior to gas/air tests, ensure that the pipeline and valve are drained to prevent frost

damage. AVK valves are designed to resist a test pressure of 1.5 x PN.

15. MAINTENANCE

The valve is designed to give long trouble free service without the need of routine maintenance.

After the specified number of operation cycles have been reached the wear inside the valve shall be examined. If the wear is

extensive, worn components shall be replaced or a new valve shall be installed.

If internal or external leakage is suspected, it is recommended that AVK International be contacted to suggest suitable remedial

action.

Page 5/8

MI GateValvesGas Rev. N June 2019 GB

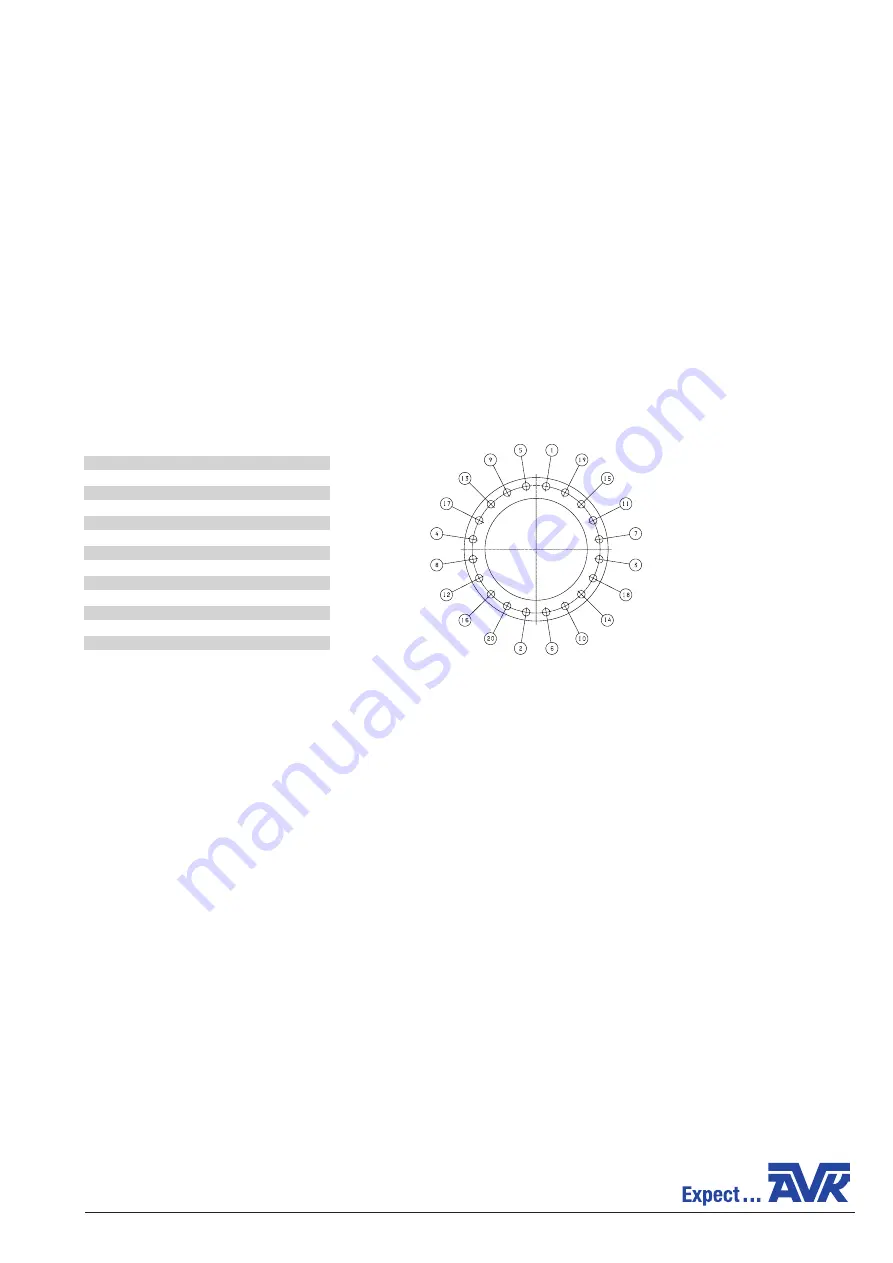

BOLT SIZES

DN Working pressure (bar)

Quantity

mm

PN 10 PN 16

PN 10 PN 16

40

M16

M16

4

4

50

M16

M16

4

4

65

M16

M16

4

4

80

M16

M16

8

8

100

M16

M16

8

8

150

M20

M20

8

8

200

M20

M20

8

12

250

M20

M24

12

12

300

M20

M24

12

12

350

M24

M24

16

16

400

M24

M27

16

16

450

M24

M27

20

20

500

M24

M30

20

20

600

M27 M30

20 20

Table 1

Figure 1