6

www.automationdirect.com/click-plc

3505 HUTCHINSON ROAD

CUMMING, GA 30040-5860

1-800-633-0405

C2-03CPU Quick Start Guide

Copyright© 2020,

Automationdirect.com

Incorporated/All Rights Reserved Worldwide

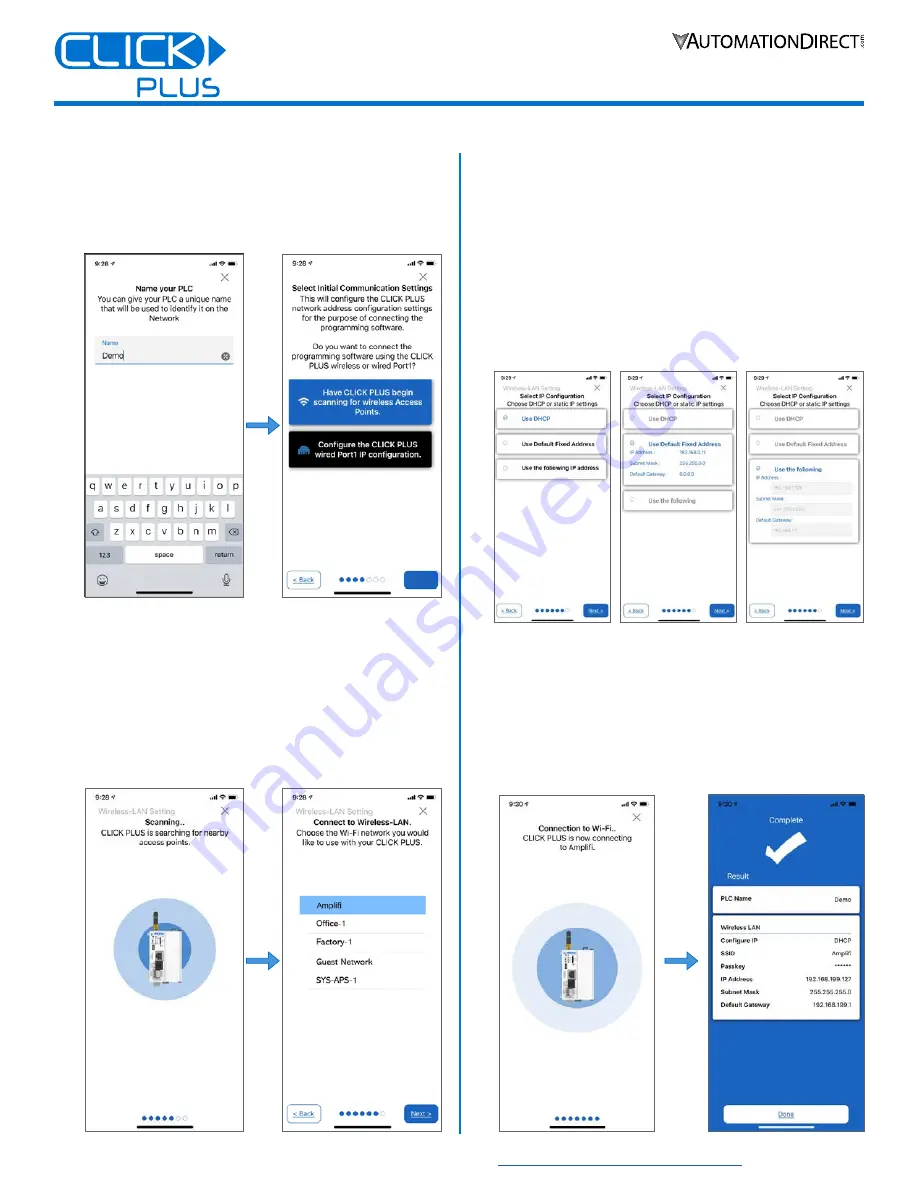

NAME THE CPU AND SELECT A PORT

6.

Enter a name for the CPU and tap

Next

. Choose a unique name

if other CLICK PLCs are on your network.

7.

Choose which network port to provision (wired or wireless).

CONNECT TO A WIRELESS ACCESS POINT

(SKIP FOR WIRED CONNECTION)

You will need an active Network Access point available within range

of the CLICK PLUS PLC, and know the password to allow the PLC

to connect to the Network.

8.

The CLICK PLC will scan for any access point within range.

Select an Access Point and type in the correct password that the

PLC will need to connect.

SET UP NETWORK PARAMETERS

9.

Once the PLC is connected to the wireless access point or wired

network, choose which IP address configuration to use, then

tap

Next

to continue.

9a.

Use DHCP

: Automatically assign a network IP address to

the CLICK PLUS PLC. This is often the simplest way to

connect.

9b.

Use Default Fixed Address

:

Wireless: 192.168.0.11

Wired: 192.168.0.10

9c.

Use the following IP address

: Manually enter valid IP

address, subnet mask, and gateway for your network.

10.

The CLICK PLUS will connect to the network and exchange

configuration information. If the settings are correct, the App

will show the Completion screen and the network settings

of the CLICK PLUS can be viewed. If using a wireless

connection, the CLICK PLUS WLAN LED will also be ON.

The PLC is now connected to the network and accessible to PCs

running the CLICK Programming Software and connected to the

same network.

Setup & Provisioning via Bluetooth, continued