57

Instructions for the installer

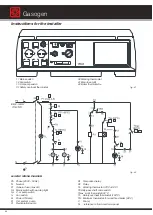

fig. 49

6.7 - COMBUSTION AIR ADJUSTMENT

PRIMARY AND SECONDARY AIR ADJUSTMENT

The GASOGEN G3 2S boiler is equipped with a

ventilation control box for combustion air (fan pos.

7 fig.2) and with primary (pos. P, fig. 47) and

secondary air adjusters. (pos. S, fig. 47).

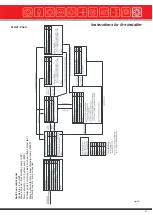

The GASOGEN G3 65 2S and GASOGEN G3 80

2S boilers are equipped with two fans (fig. 48)

which incorporates a non-return valve, controlled by external

ring nuts. The upper fan supplies the primary air, the lower fan

the secondary air.

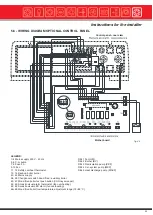

During the first ignition it is necessary to adjust the primary

and secondary air, keeping in mind that the primar y air

determines the boiler’s output and therefore the quantity of

wood burnt, whilst the secondary air completes the combustion.

For correct air adjustment it will be necessary to observe the

flame through the sight glass placed on the lower door. The

flame will have to occupy about two thirds of the combustion

chamber, and will have to quietly lick the lower cradle, without

moving the ash too much and without making any noise.

The flame must be an orange-pink-white colour, not too

transparent and with the centre part veering to light blue.

To bring the flame to optimal conditions, it will therefore be

necessary to regulate the primary air by screwing or unscrewing

the screw (pos. P); the same operation must be carried out for

the secondary air (pos. S).

For the GASOGEN G3 65 2S and GASOGEN G3 80 2S boilers

the primary air adjustment is achieved by acting on the upper

fan’s external ring nut; for the secondary air by acting on the

lower fan’s external ring nut.

Example n.1

Thick, wet wood logs = difficult combustion

S - Very closed (try to get the maximum dimension of the flame,

but not a reddish colour).

P - Reasonably open in order to obtain a sufficient gasification.

Example n. 2

Very inflammable wood logs

S - Completely open.

P - Slightly closed to reduce the gasification, but sufficiently

open to evacuate the ash that can close the combustion head.

GENERAL SUGGESTIONS

- Better performances are obtained after two - three days of

operation. The refractory cement, in fact, needs to be baked

and the tar has to cover the upper part of the fire box.

-

The flame has to have good dimensions and reasonably

fill-up the combustion chamber.

- The

flame

must not be

too red

(lack of secondary air S).

- The

flame

must not be

too blue

(excess of secondary air S).

- The

flame

must not be

too noisy

(excess of primary air P).

- The

flame

must not be

too small

(lack of primary air P).

- If

the ash does not falls down properly

- increase the

primary air P.

- If

too much ash falls down -

reduce the primary air P.

- If

the chimney smokes -

open the secondary air S

completely.

- If

the chimney continues smoking

- adjust the secondary

air S to maximum and reduce the primary air. P.

AIR ADJUSTMENT FAULTS

1) If

the primary air is excessive

a lot of ash and small pieces

of coal will fall through the slot into the combustion chamber.

The flame is too fast, dry, a cold colour and makes a noise.

The boiler is consuming a lot of wood and the door’s refractory

insulation is white.

2) If

the primary air is insufficient

the flame will be slow,

indecisive, influenced by air currents and by the chimney

draught, very small, incapable of touching the lower cradle,

with low ash production and the door’s refractory insulation

will be of a dark colour.

3) If

the secondary air is excessive

the flame will be small, a

blueish colour and very transparent.

4) If

the secondary air is insufficient

the flame will be big, it

will touch the lower cradle, it will completely fill the combustion

chamber and, above all, it will be a red colour and not

transparent

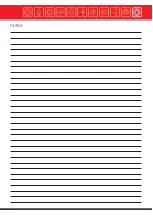

Cut

Summary of Contents for Gasogen

Page 1: ...Wood Fired Boiler Gasogen 29 93kW Installation and Servicing Manual ...

Page 66: ...Gasogen notes ...

Page 67: ...notes ...