56

Instructions for the installer

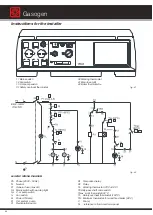

P

S

1

S1

P1

S

S

P

P1

C

6.6 - START-UP

IGNITION

Make sure all the controls listed in 6.5 have been

carried out.

For the GASOGEN G3 25 2S, GASOGEN G3 40 2S and

GASOGEN G3 50 2S models:

Screw down completely the

primary air’s

(

P

) adjustment screw

Screw down completely the

secondary air’s

(

S

) adjustment

screws until you “detect” the resistance of the spring pushing

the closing discs.

Now, “

unscrew

” about

10 turns

the

primary

Air’s

(

P

) screw and

4 turns

the

secondary air’s

(

S

) screws.

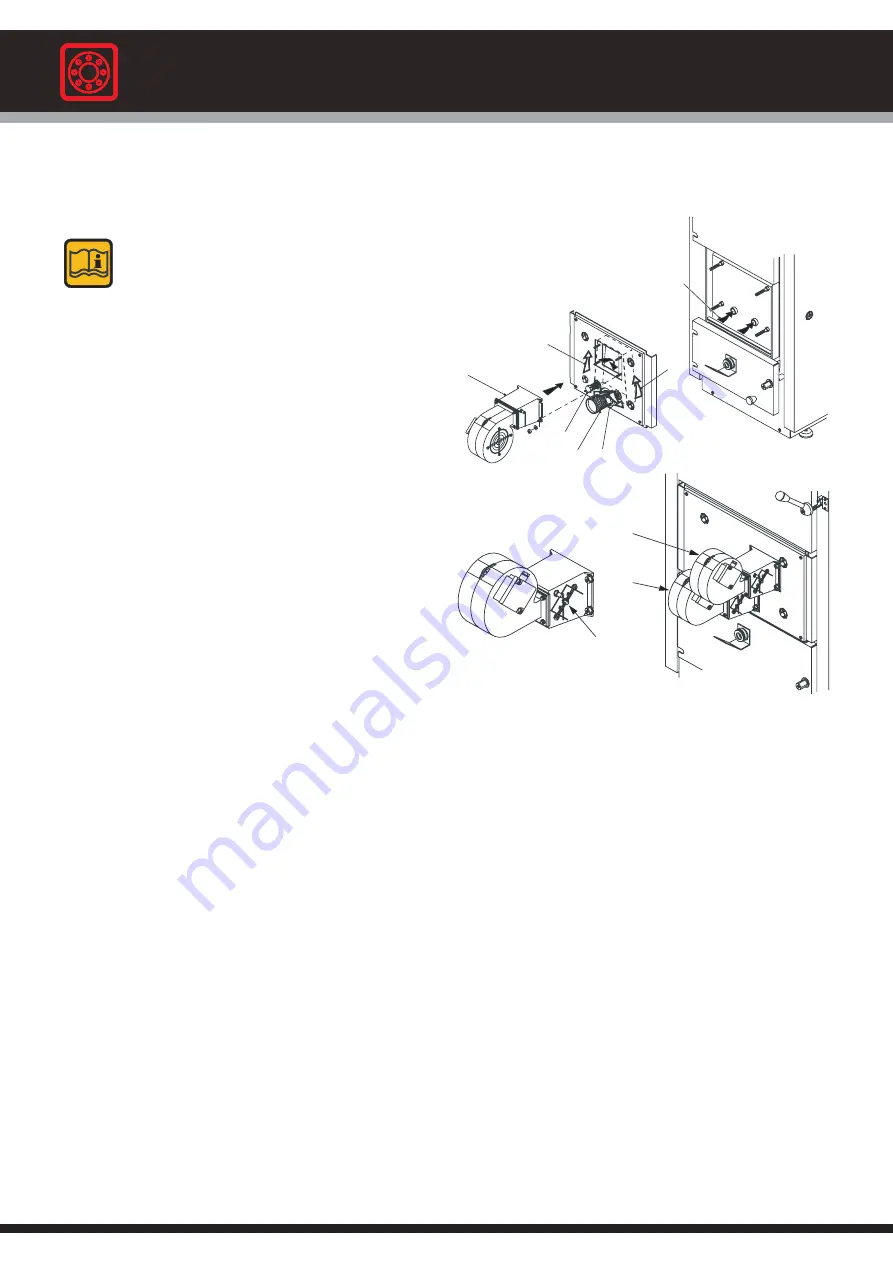

For the GASOGEN G3 65 2S and GASOGEN G3 80 2S

models:

The initial position of the ring nuts

(pos. 1, fig. 48) which

control the opening or closing of the primary and secondary

air,

has to be about in the middle of the threaded rod.

The primary air (P) is blown through the upper fan, whilst the

secondary air (S) is blown through the lower one.

At this point,

“screw”

or

“unscrew”

the ring nuts (pos. 1, fig.

48) on the threaded rod until you have an optimal air regulation,

by observing the colour of the flame in the combustion chamber;

keep in mind that by rotating the ring nuts in a clockwise

direction (that is upwards) you will have an increase of the

emission of the air (primary or secondary), vice versa, a

reduction.

Open the upper loading door and place above the main stone’s

central slot, some thin and dry pieces of wood, in a crosswise

position.

Prefer easily inflammable wood, avoiding big pieces and square

shaped pieces.

Open the lower combustion chamber door.

Using sheets of thin paper (newspapers or similar) light the

wood previously placed inside.

Leave the upper door ajar.

Wait several minutes until the fire starts and produces some

embers (about 5 - 10 minutes).

Close the lower door first and then the upper door: at this

moment the fan is automatically switched ON (point 6.1).

After some minutes, if you look through the sight glass, it is

possible to see that the flame

starts reversing downwards, so you can add some other larger

wood pieces.

Important: during boiler operation the bypass must be

always perfectly closed.

The wood has to be of the following length, according to the

boiler model:

a) 50 cm (+ 1 cm, - 4cm) for the GASOGEN G3 25 2S and

GASOGEN G3 40 2S models

b) 70 cm (+ 1 cm, - 4 cm) for the GASOGEN G3 50 2S and

GASOGEN G3 65 2S models

c) 100 cm (+ 1 cm, - 4 cm) for the GASOGEN G3 80 2S model

These dimensions must be absolutely respected.

In order to have a good combustion it is essential that the wood

falls down in a uniformed way. Therefore it is necessary to make

sure that the length of the wood logs introduced, their shape

fig. 47

C = Ventilation control box

S= Secondary air adjusting screws

P= Primary air adjusting screw

P1 = Primary air passages

S1= Secondary air passages

and the way they are loaded does not prevent the wood from

falling down in a regular way.

The wood logs must be placed lengthwise and in a horizontal

direction.

No log must be placed in an oblique or slanted direction.

SUBSEQUENT WOOD LOADINGS

Before carrying out a new loading of wood use up the previous

load as much as possible.

The new load can be made when the bed of embers is about 5

cm thick.

Slowly open the upper loading door and the inner anti smoke

flap.

The wood logs must have the length specified in the previous

paragraph and they must be placed as previously described.

USEFUL SUGGESTIONS and LOADING ERRORS TO BE

AVOIDED

- Logs too long do not fall down properly and can cause

obstructions.

- Logs too short cause irregular air passages, with consequent

reduction in output and efficiency.

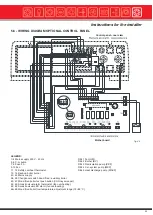

- In case the quality of the wood causes “obstructions” it could

become necessary to cut the wood logs in two parts, as shown

in fig. 49, in order that the total length “L” is as indicated in the

previous paragraph.

- Always open the upper door slowly in order to avoid blowbacks

and smoke formation.

- During normal boiler operation it is absolutely forbidden to

open the lower combustion door.

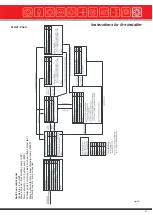

fig. 48

P= Primary air ventilation control box

S = Secondary air ventilation control box

1 = Ring nut air adjustment

Models: GASOGEN G3 25 2S

GASOGEN G3 40 2S

GASOGEN G3 50 2S

Models: GASOGEN G3 65 2S

GASOGEN G3 80 2S

Gasogen

Summary of Contents for Gasogen

Page 1: ...Wood Fired Boiler Gasogen 29 93kW Installation and Servicing Manual ...

Page 66: ...Gasogen notes ...

Page 67: ...notes ...