15

Blade

Structure

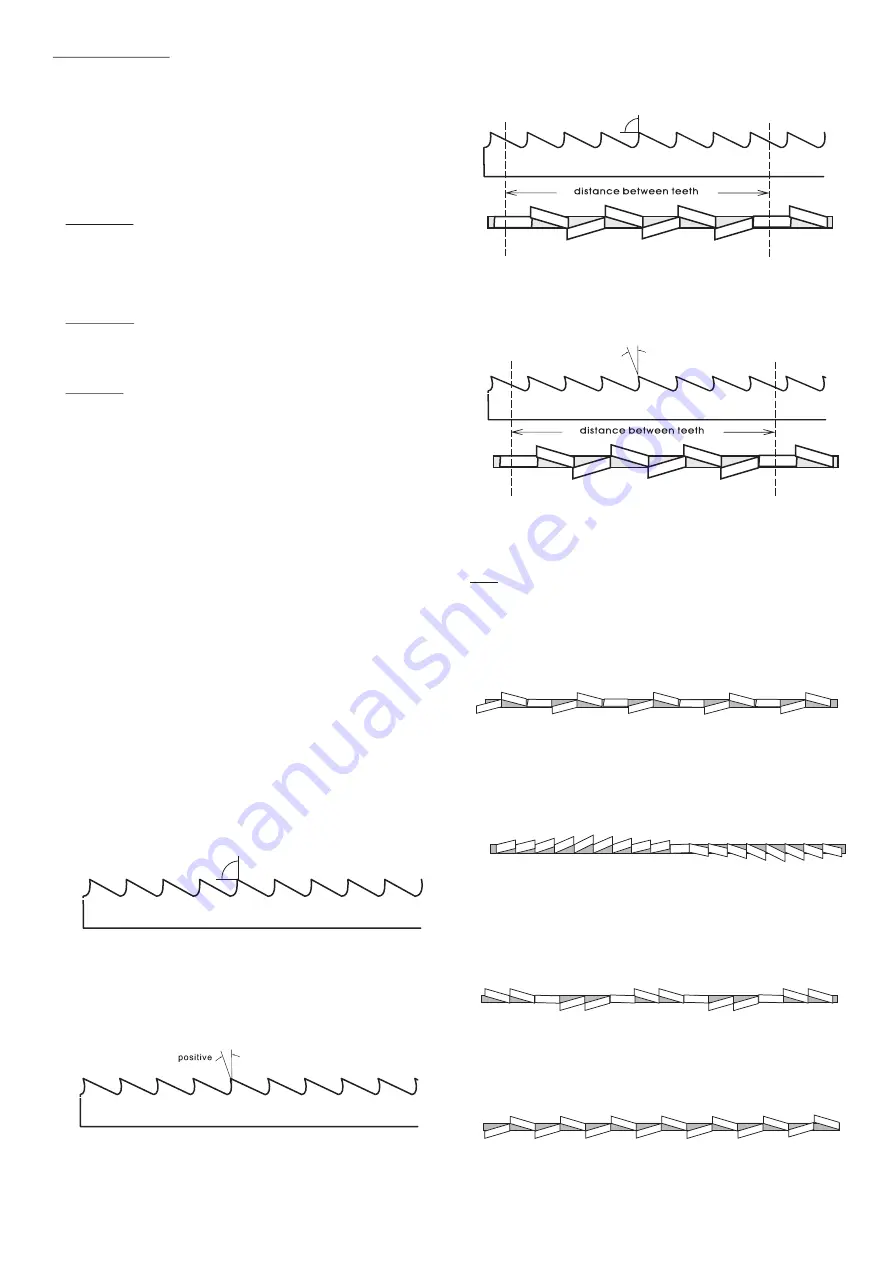

COMBO TOOTH

Pitch varies between teeth and consequently varying teeth

size and varying gullet depths. Pitch varies between teeth,

Bi-metal blade are the most commonly used. They consist of

which ensures a smoother, quieter cut and longer blade life

silicon-steel blade backing by a laser welded high speed steel

owing to the lack of vibration.

(HSS) cutting edge. The type of stock are classified in M2, M42,

M51 and differ from each other because their major hardness

due to increasing percentage of Cobalt (Cc) and molybdenum

(Mo) contained in metal alloy.

There

are

several

key

factors

to

consider

in choosing

a

blade

:

Tooth

Pitch---The

number

of

teeth

per

inch

(

TPI

)

on

the

blade

,

also

known

as

tooth pitch

.

Select

a

pitch

which

will

assure

that at

least

three

teeth

are

contacting

the workpiece

while

cutting

.

This

helps

to

Another advantage offered in the use of this type of blade in

distribute the

cutting

forces

and

avoids

tooth

the fact that with an only blade it is possible to cut a wide

breakage

.

range of different material in size and type.

Tooth

Form---There

are

four

common

forms of

teeth

on

the

COMBO TOOTH

blade

:

buttress

,

claw

-

tooth

,

precision

and

tungsten

O

O

9 -10 positive rake

carbide

.

Precision

is the

most

common

and

is

the

type

supplied with

this

saw

.

Tooth

Set---Set

is

the

degree

to

which

the teeth

are

bent

away

from

the

blade

.

Typical tooth

set

styles

are

raker

,

wave

and

straight set

.

Always

select

and

use

good

-

quality

saw

blades and

choose

the

right

blade

for

the

job

.

Discuss your

cutting

requirements

with

your

saw

blade dealer

to

make

sure

you

are

getting

the

type

of blade

which

best

suits

your

need

.

Poor

quality blades

and

improper

use

are

often

the

cause

This type of blade is the most suitable for the cutting of

of premature

blade

failure

.

section bars and large and thick pipes as well as for the

cutting of solid bars at maximum machine capacity. Available

Many

conditions

can

lead

to

breakage

.

Blade breakage

is

,

in

pitches: 3-4/4-6.

some

cases

,

unavoidable

,

since

it is

the

natural

result

of

the

peculiar

stresses

that bandsaw

blades

are

subjected

to

.

Sets

Blade

breakage is

also

due

to

avoidable

causes

.

Saw teeth bent out the plane of saw body, resulting in a wide

Avoidable breakage

is

most

often

the

result

of

poor

care

cut in the work-piece.

or

judgement

on

the

part

of

the

operator

when mounting

or

adjusting

the

blade

or

support

guides

.

The

most

common

Regular or Raker Set

causes

of

blade

breakage

are

:

Cutting teeth right and left, alternated by a straight

tooth.

(1) faulty

alignment

and

adjustment

of

the

guides

;

(2) insufficient

number

of

teeth

contacting

the

cut

;

(3) feeding

too

fast

;

(4) tooth

dullness

or

absence of

sufficient

set

;

Of great use for materials with dimensions superior to 5mm.

(5) excessive

tension

;

Used for cutting of steel, castings and hard nonferrous

(6) using a

blade

with

a

lumpy

or

improperly

finished

materials.

weld

;

and

(7) continuously

running

the

bandsaw

when not

in

use

.

Wavy Set

REGULAR TOOTH

Set in smooth waves.

O

0 rake and constant pitch

This set is associated with very fine teeth and it is mainly

used for cutting of pipes and thin section bars (from 1-3mm).

Most common form for transversal or inclined of solid small and

Alternate Set (in groups)

average cross-sections or pipes, in laminated mild steel and

Groups of cutting teeth right and left, alternated by a

gray iron or general metal.

straight tooth.

POSITIVE RAKE TOOTH

O

O

9 -10 positive rake and constant pitch

This set is associated with very fine teeth and it is used for

extremely thin materials (less than 1mm).

Alternate Set( individual teeth)

Cutting teeth right and left.

Particular use for crosswise or inclined cuts in solid sections or

large pipes, but above all harder materials (highly alloyed and

This set is used for the cutting of nonferrous soft materials,

stainless steels, special bronze and forge pig iron).

plastics and wood.

Summary of Contents for LM-270

Page 27: ...26 24 4 A 330...

Page 28: ...27 68 328 329 66A...

Page 29: ...28 209A 325 326 327 211 212 213...

Page 30: ...29...