REV. 01 2012

15 / 35

6.2.1

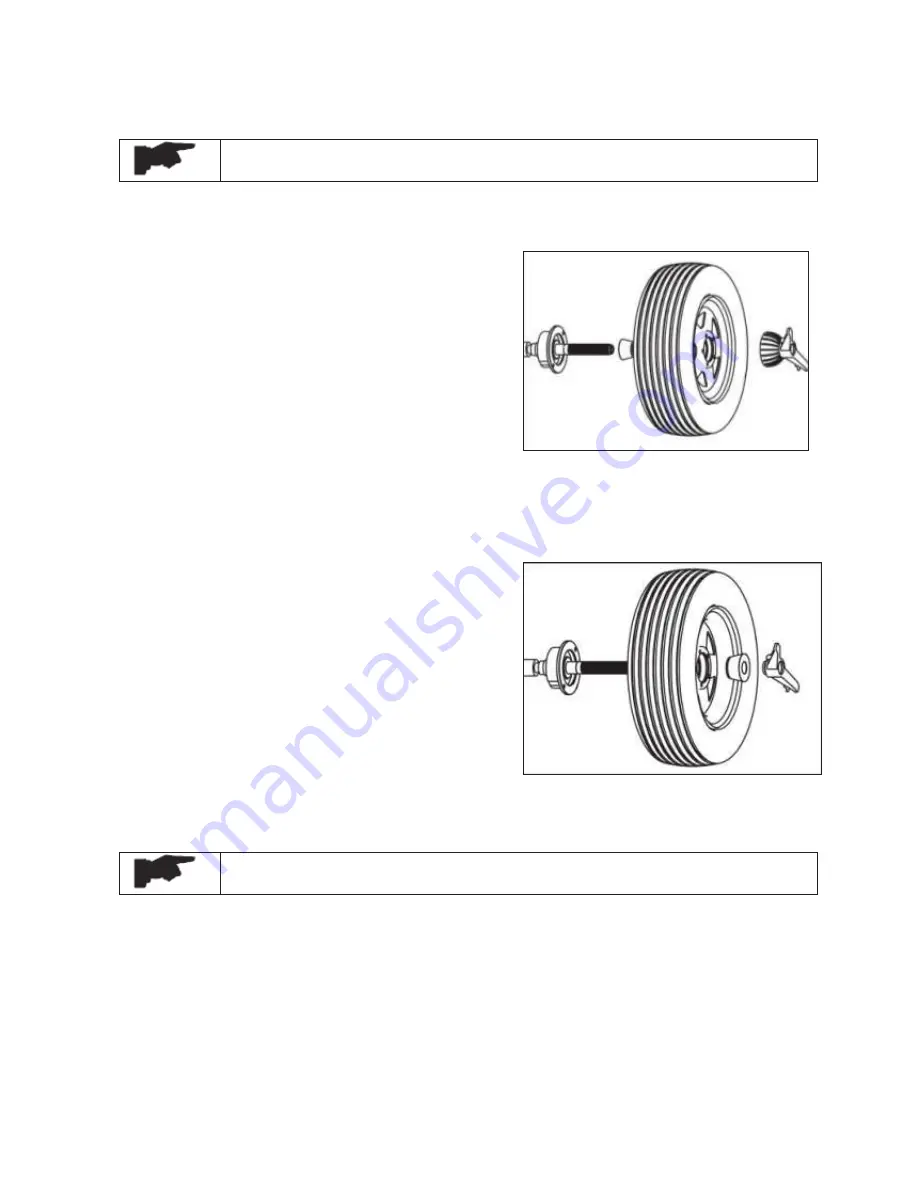

STANDARD BACK CONE MOUNTING (ref. Fig. 12)

Carefully clean the component surface before performing any operation.

Most steel wheels can be mounted properly using this method. The wheel is centered on a cone from

the inner side of the hub.

x

S

elect the cone that best fits the centre hole in the

wheels. Slide the cone onto the shaft with the

large end towards the faceplate.

x

L

ift the wheel onto the shaft and centre it on the

cone.

x

A

ttach the pressure cup to the quick locking nut

and install the assembly onto the shaft. Tighten

securely.

6.2.2 STANDARD FRONT CONE MOUTING (ref. Fig. 13)

A wheel should be centered by the outer side of the hub only when the inner surface will not provide

an accurate surface to center on.

x

S

elect the cone that best fits the center hole in the

wheel.

x

L

ift the wheel onto the shaft and slide it back

against the shaft faceplate.

x

Slide the cone onto the shaft and into the center

of the wheel. You will need to lift the wheel to

seat the cone in the centre hole.

x

I

nstall the quick locking nut (without the pressure

cup) onto the shaft. Tighten securely against the

cone

6.3

SETTINGS OF WHEEL DIMENSIONS

Before balancing a wheel, wheel dimensions must be measured correctly.

6.3.1

WHEEL DIMENSIONS

6.3.1.1

STANDARD MODES

Measure the wheel dimensions as shown in the figure 14

6.3.1.2

ALU

ƿ

ƿ

MODES

Measure the wheel dimensions as shown in the figure 15.

Fig. 12

Fig. 13

Summary of Contents for WB55

Page 1: ......

Page 35: ...REV 01 2012 35 35 CHAPTER 12 ELECTRIC DIAGRAM...