17

I

NSTRUCTION MANUAL

F

UEL SYSTEM

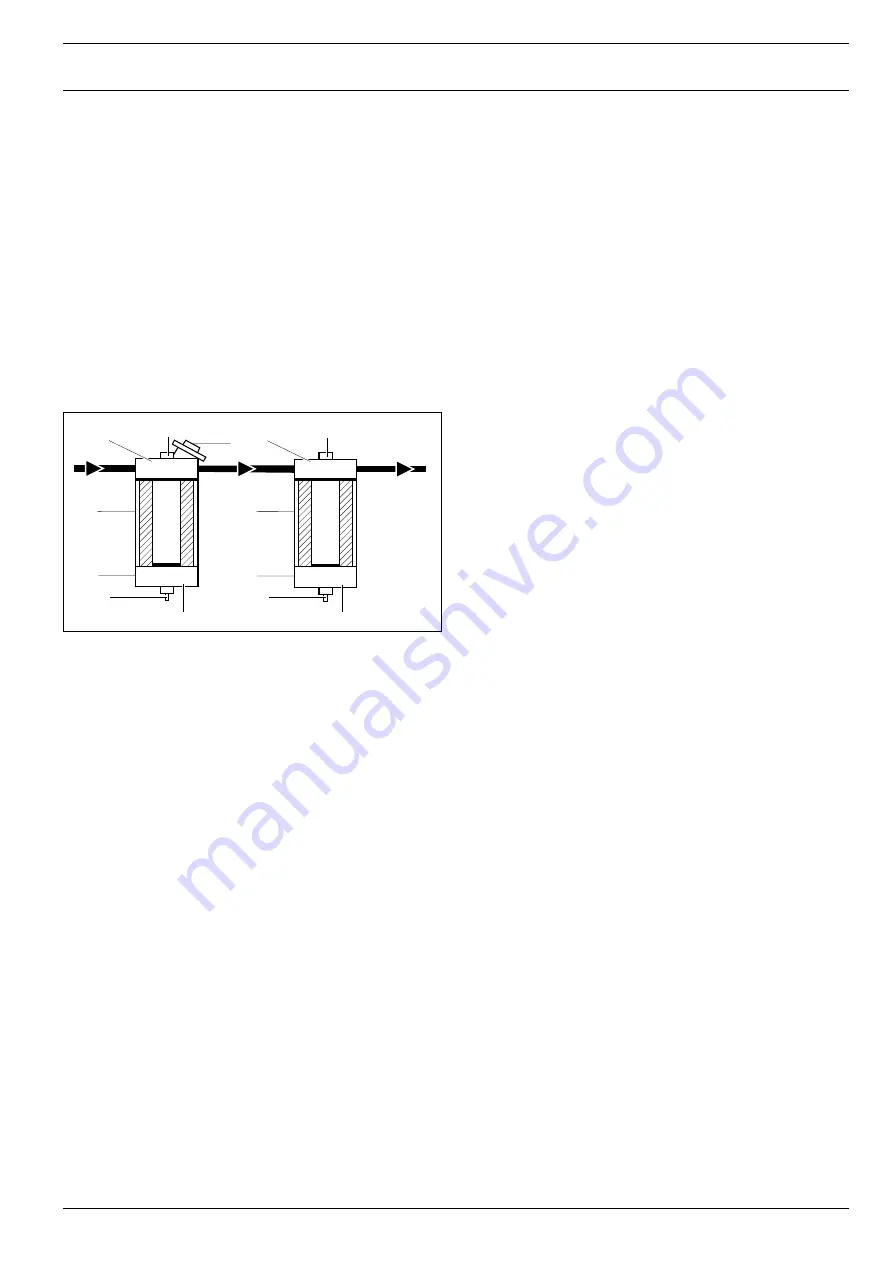

The fuel filter assembly strains out water and impurities from the

fuel.

The fuel is drawn from the tank the through the fuel pre-filter (FF1)

and the fuel fine-filter (FF2) to the engine injection pump.

Only one third of the fuel drawn is used for combustion. The

remnant is used to cool the injection pump and is returned to the

tank via a fuel cooler.

The fuel cooler is located behind the grating at the right-hand side of

the compressor.

The fuel filters each consist of an adapter head, a spin-on filter

element and a waterseparator bowl.

DV1,2 Drain valve

1

Adapter head

FF1

Fuel pre-filter

2

Filter element

FF2

Fuel fine-filter

3

Filter bowl

VP1,2

Vent plug

4

Hand-pump

Draining the fuel pre-filter

1. Open the bowl drain valve (DV1) and pump water out.

2. Close the drain valve.

Draining the fuel fine-filter

1. Open the bowl drain valve (DV2) to evacuate water.

2. Close the drain valve.

Replacing the fuel pre-filter element

1. Drain the fuel from the bowl.

2. Remove the filter and separate the bowl from the element.

3. Apply a film of gas oil to the new bowl seal.

4. Screw the bowl to the new element tightly by hand.

5. Apply a film of gas oil to the new element seal.

6. Screw on the filter tightly by hand.

7. Open the head vent and operate the pump. Close the vent when

fuel begins to purge.

8. Check for leaks, retighten if necessary.

Replacing the fine-filter element

1. Drain from the bowl.

2. Remove the filter and separate the bowl from the element.

3. Apply a film of gas oil to the new bowl seal.

4. Screw the bowl to the new element tightly by hand.

5. Apply a film of gas oil to the new element seal.

6. Fill the element with fuel and screw on the filter tightly by hand.

7. Check for leaks, retighten if necessary.

C

OOLANT

The coolant is a mixture of water and anticorrosion/antifreeze agent.

The coolant must remain in the system all the year round to ensure

adequate corrosion protection and to increase the boiling point.

Renew the coolant every two years, as the corrosion protection

diminishes.

It is not permitted to use water alone as a coolant even if antifreeze

properties are not required. The water in the coolant has to satisfy

certain requirements, which are frequently, but not always, met by

drinking water. If the quality of the water is insufficient, the water

has to be treated. Information regarding this can be obtained from

any Mercedes-Benz Service Station.

The portion of anticorrosion/antifreeze agent in the coolant must not

drop below 40 % by volume during operation (equals antifreeze

protection down to approximately -25 ¡C). A lower portion does not

adequately ensure the anticorrosive properties.

To avoid any damage to the cooling system:

Ð

Use only approved anticorrosion/antifreeze agents. Information

is available from any Mercedes-Benz Service Station.

Ð

When replenishing the system (after loss of coolant) it is

essential to ensure an anticorrosion/antifreeze portion of 50 %

by volume (antifreeze protection down to -37 ¡C).

Ð

Do not use more than 55 % by volume of anticorrosion/

antifreeze agent (= maximum antifreeze protection). Otherwise

the antifreeze properties will be reduced and the heat dissipation

impaired.

In exceptional cases, where it is evident that no anticorrosion/

antifreeze agent can be obtained and no antifreeze protection is

required (e. g. tropics), 1 % by volume = 10 cm

3

/litre of corrosion

protection oil must be added. In such cases, renew the coolant

annually.

DV1

1

2

FF1

VP1

3

4

DV2

1

2

FF2

VP2

3

Summary of Contents for XRVS455 Md

Page 2: ...2 XRVS455 Md ...

Page 26: ...26 XRVS455 Md ...