PFD1500RA-180

EN

Troubleshooting

© Atlas Copco Industrial Technique AB - 9836 6024 01

55

Problems

Possible reasons

Actions

The spindle retracts before the

drilling cycle is completed. The rapid

advance* button functions properly.

Depth valve leaks.

1. Remove the drilling depth valve.

2. Do a leak test of the valve, see

the section “Leak test”.

3. If the results of the test are un-

satisfactory, replace the valve and

complete the procedure. If the test

shows no fault, continue the proce-

dure.

Overload protection valve leaks.

4. Remove the overload protection

valve.

5. Do a leak test of the valve, see

the section “Leak test”.

6. If the results of the test are un-

satisfactory, replace the valve and

complete the procedure. If the test

shows no fault, continue the proce-

dure.

Overload protection activates due

to excessive feed force.

7. Test the drill without load.

8. If the drill functions correctly

when unloaded, optimize the load

by reducing the feed rate or chang-

ing the drill bit. Then complete the

procedure. If the test without load

shows no improvement, continue

the procedure.

Overload clutch is stuck in the

open position.

9. Remove the feed cassette.

10. Remove the overload clutch. If

the clutch makes a loud click, it has

been released. Install the clutch in

the original position and test the

drill. If the drill performance im-

proves, complete the procedure.

11. Do a test of the clutch accord-

ing to the section “Test of overload

clutch”.

12. If the results of the test are un-

satisfactory, replace the clutch and

complete the procedure. If the test

shows no fault, continue the proce-

dure.

13. Install the clutch in the original

position.

14. Install the feed cassette in the

original position. Complete the pro-

cedure.

* Optional feature.

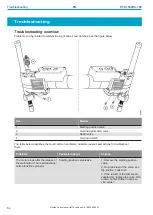

Test of overload clutch

1.

Fasten the test tool in a vise.

2.

Attach the clutch to the connector (3) and put the hexagonal tool on the clutch. See the figure below.

3.

Tighten the clutch counterclockwise to 10 Nm ±2 Nm. If the clutch operates correctly, it releases with

a loud click within the specified torque range.

Summary of Contents for PFD1500RA-180

Page 15: ...PFD1500RA 180 EN Installation Atlas Copco Industrial Technique AB 9836 6024 01 15 ...

Page 16: ...Installation EN PFD1500RA 180 16 Atlas Copco Industrial Technique AB 9836 6024 01 ...

Page 26: ...Installation EN PFD1500RA 180 26 Atlas Copco Industrial Technique AB 9836 6024 01 ...

Page 48: ...Service EN PFD1500RA 180 48 Atlas Copco Industrial Technique AB 9836 6024 01 ...

Page 58: ......

Page 59: ......