16

Installation instructions "1552 - EN"

Adjustment

Recommendations for measuring combustion

Fine tune the burner so that it meets the existing local regulations.

It is important that the flow of combustion products between the chimney and the furnace nozzle is sealed in order to avoid

measurement errors.

In order to measure combustion: Keep to the burner's operating times:

• 10 min operation (Boiler at temperature).

• 20 min operation (Cold boiler).

After assembling and setting the burner:

• Check the soot index.

• Check the smoke gas emission values.

Keep to the advised settings to avoid having flame surveillance problems at low powers

Recommendations for adjusting the recirculation slot

The recirculation gas proportion is based on the recirculation slot. This gas proportion directly affects the NOx rate.

The larger the recirculation slot, the lower the NOx rate. However, flame stability decreases. The recirculation slot

must be set to obtain the lowest possible NOx rate with good flame stability.

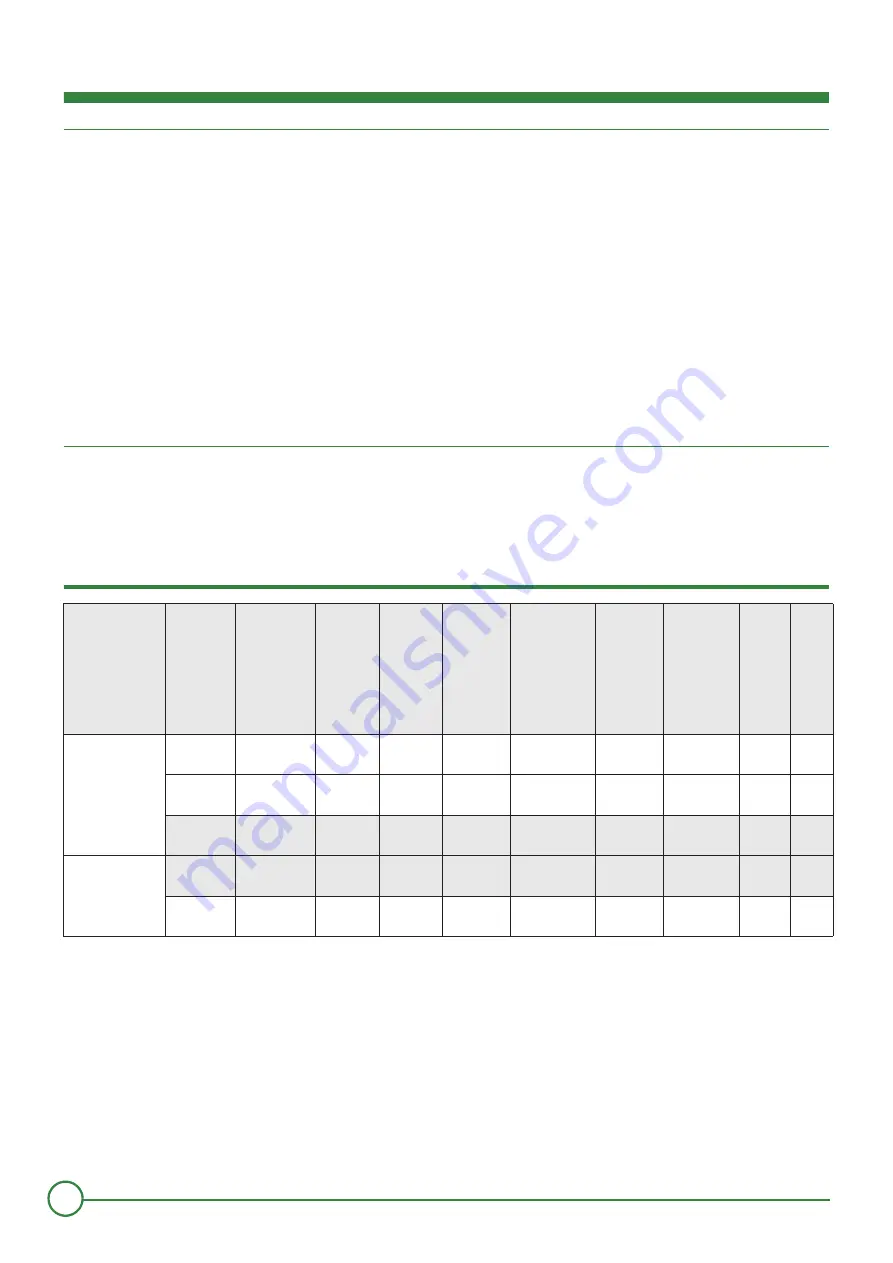

1 Recommended Settings

(1)

Ring from 1 mm

In grey: factory setting

Burner

Burner

power

(kW)

Filler

(USG)

Fuel oil

pressure

(bar)

Head

pressure

(mbar)

Air valve

setting

indication

Recirculatio

n slot (mm)

Position

of the

head -

Distributi

on bar

(Indicativ

e setting)

Number of

rings

4

(1)

Side

3

(mm)

CO

2

(%)

ATL F10E2-1.28

23

Danfoss

0.55 - 80°S

10

6.5

15

2

8

2

2.5

12.5

25

Danfoss

0.55 - 80°S

12

7.8

45

2

8

2

2.5

12.5

28

Danfoss

0.55 - 80°S

14

8.6

110

2

8

2

2.5

12.5

ATL F10E2-1.33

28

Danfoss

0.55 - 80°S

14

6.7

90

2

5

4

2

13

30

Fluidics

0.65 - 60°SF

12

7.5

120

2

5

4

2

13