12

Keep children away form machine.

Never operate the machine if other persons are in the imme-

diate vicinity.

Never leave the device unattended.

Keep your workplace in an orderly condition! Untidiness

can result in accidents.

Choose a working position alongside the equipment or be-

hind it. Never stand near the ejection opening.

Never reach into the filling or ejection opening.

Keep your face and body away from the filling opening.

Do not overload the machine! You work better and safer in the

given performance range.

Only operate the machine with complete and correctly at-

tached safety equipment and do not alter anything on the

machine that could impair the safety.

Do not alter the revolution speed of the motor, since this con-

trols the safe maximum operating speed, and protects the mo-

tor and all rotating parts against damage due to excess

speed.

Do not operate without the funnel.

Do not modify the device or parts of the device respectively.

Close machine properly before enabling motor.

Do not hose down the device with water. (Origin of danger

electric current).

Take into consideration environmental influences:

−

Do not use the device in moist or wet ambience.

−

Do not leave the machine standing in the rain or use

when raining.

−

Provide for good illumination.

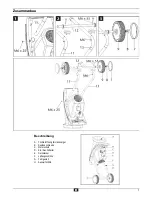

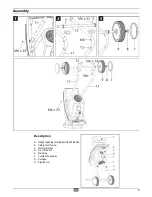

To prevent danger of injury to fingers during assembly or

cleaning operations hold the cutting mechanism (see pic.

page 14) and wear protecting gloves.

Switch the machine off and remove the mains plug from the

socket when

−

Performing maintenance and cleaning work.

−

Eliminating faults.

−

Checking connecting lines, whether these

are knotted or damaged.

−

Transporting.

−

Carrying out repair work.

−

Changing the blades.

−

Leaving unattended (even during short interruptions).

If the machine’s filling funnel or ejection slot is blocked switch

off the motor and disconnect the mains plug before removing

material from the filling funnel or ejection slot.

Check the machine for possible damage:

−

Before further use of the machine the safety devices must

be checked carefully for their proper and intended func-

tion.

−

Check whether movable parts function perfectly and do

not stick or whether parts are damaged. All parts must be

correctly installed and fulfil all conditions to ensure perfect

operation of the machine.

−

Damaged safety devices and parts must be properly re-

paired or exchanged by a recognized, specialist workshop;

insofar as nothing else is stated in the instructions for use.

−

Damaged or illegible safety labels have to be replaced.

Store unused equipment in a dry, locked place out of the

reach of children.

E

E

l

l

e

e

c

c

t

t

r

r

i

i

c

c

a

a

l

l

s

s

a

a

f

f

e

e

t

t

y

y

Design of the connection cable according to IEC 60 245 (H

07 RN-F) with a core cross-section of at least

−

1.5 mm

2

for cable lengths up to 25 m

−

2.5 mm

2

for cable lengths over 25 m

Long and thin connection lines result in a potential drop. The

motor does not reach any longer its maximal power; the func-

tion of the device is reduced.

Plugs and coupler outlets on connection cables must be made

of rubber, plasticised PVC or other thermoplastic material of

same mechanical stability or be covered with this material.

The connector of the connection cable must be splash-proof.

When running the connection line observe that it does not

interfere, is not squeezed, bended and the plug connection

does not get wet.

Wind off completely the cable when using a cable drum.

Do not use the cable for purposes for which it is not meant.

Protect the cable against heat, oil and sharp edges. Do

not use the cable to pull the plug from the socket.

Regularly check the extension cables and replace them if

they are damaged.

Do not use any defective connection cables.

When working outdoors, only use extension cables especially

approved and appropriately labelled for outdoor use.

Do not set up any provisional electrical connections.

Never bypass protective devices or deactivate them.

Only hook up the machine by means of a fault-current cir-

cuit breaker (30 mA).

The electrical connection or repairs to electrical parts of

the machine must be carried out by a certified electrician or

one of our customer service points. Local regulations –

especially regarding protective measures – must be ob-

served.

Repairs to other parts of the machine must be carried out

by the manufacturer or one of his customer service points.

Use only original spare. Accidents can arise for the user

through the use of other spare parts. The manufacturer is

not liable for any damage or injury resulting from such ac-

tion.

C

C

o

o

m

m

m

m

i

i

s

s

s

s

i

i

o

o

n

n

i

i

n

n

g

g

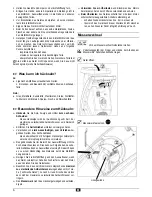

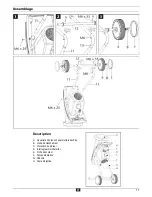

Check that the machine is completely and correctly assem-

bled.

To avoid toppling, place the shredder on a firm horizontal

surface.

Do not place the equipment on ground which is paved or

surfaced with gravel.

The machine should only be operated in the open. Always

maintain a safe distance (at least 2 m) from walls or other

fixed objects.

Before each use, check

−

Connection cables for defects (cracks, cuts, etc.).

Do not use any defective cables.

−

There are no damage at the machine (see safety instruc-

tions).

−

All screws are tight.

Summary of Contents for MHD 2200

Page 125: ...124 ...

Page 131: ...129 ...