Manual, F/T Sensor, Serial Axia

Document #9610-05-Serial Axia-05

Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 • Tel:+1 919.772.0115 • Fax:+1 919.772.8259 •

45

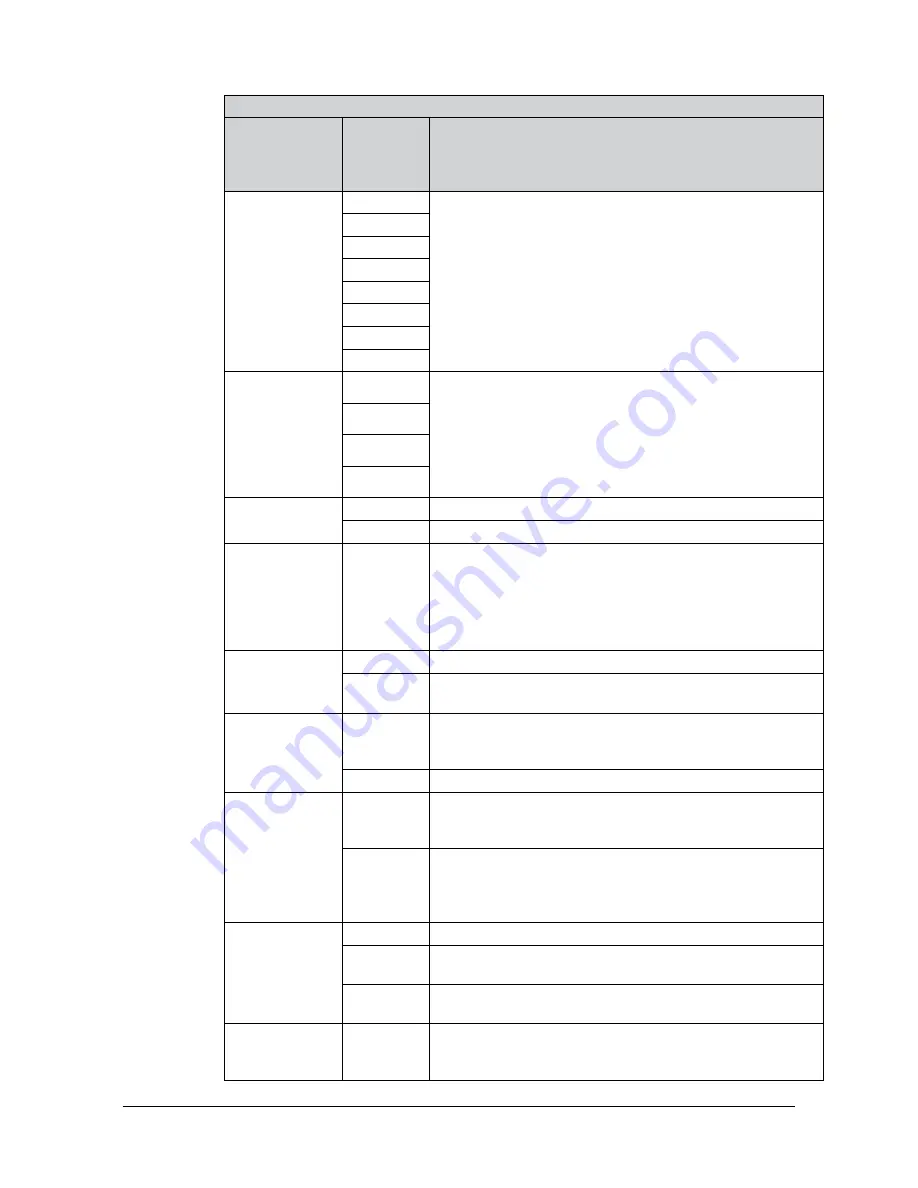

Table 5.1—Secondary “c” or “s” Commands

Category

Secondary

Command

or

Specifier

Notes

Gage

number(s).

0

Gage values are printed in counts only.

As many as all gage numbers can be reported or as few as

a single gage number.

1

2

3

4

5

6

7

Axis.

x

The user can choose to view force and torque data in the x,

y, z axis. The output value can be displayed in F/T counts

or engineering units. Counts are converted to units by

scaling or dividing the count value by the cpf or cpt. Refer to

Section 5.3.1—Converting Counts Per Force/Torque to FT

Values

y

z

m

Force and/or

Torque.

f

The XYZM force data is displayed.

t

The XYZM torque data is displayed.

Magnitude

m

Force or torque data is displayed as the magnitude of the

vector components in the x, y, and z axis. The output value

can be displayed in F/T counts or engineering units. Counts

are converted to units by scaling or dividing the count value

by the cpf or cpt. Refer to

Section 5.3.1—Converting Counts

.

Counts or Units.

c

The XYZM data is displayed in counts.

u

The XYZM data is displayed with the selected user units, for

example: N or Nm. Units are the default setting.

Numeric

System.

h

The data is displayed as a hexadecimal number. Except

any data printed in units is always displayed as a decimal

number by default.

d

The data is displayed as a decimal number.

Format.

>

The data is displayed in a formatted human-readable

output,for example: lined-up columns. “>” is the default

setting.

<

The data is displayed in a compressed output that has no

leading zeros, trailing zeros, or unnecessary blanks. This

output is intended for high-speed applications that are used

in an automated setting.

Additional inputs

to aid in the

development

of a software

program.

s

This command specifies a CRC.

#

This command specifies a sample counter that is

incremented each time that a “c” or “s” line is printed.

@

This command specifies an ADC read counter that is

incremented each time that the ADC is read.

Troubleshooting

!

This command specifies the 32-bit status code. Refer

to

Section 5.3.4—How to Interpret the Output from “!”

.