01.03.2020 v3

2. SPECIFICATIONS AND OPERATING ENVIRONMENT

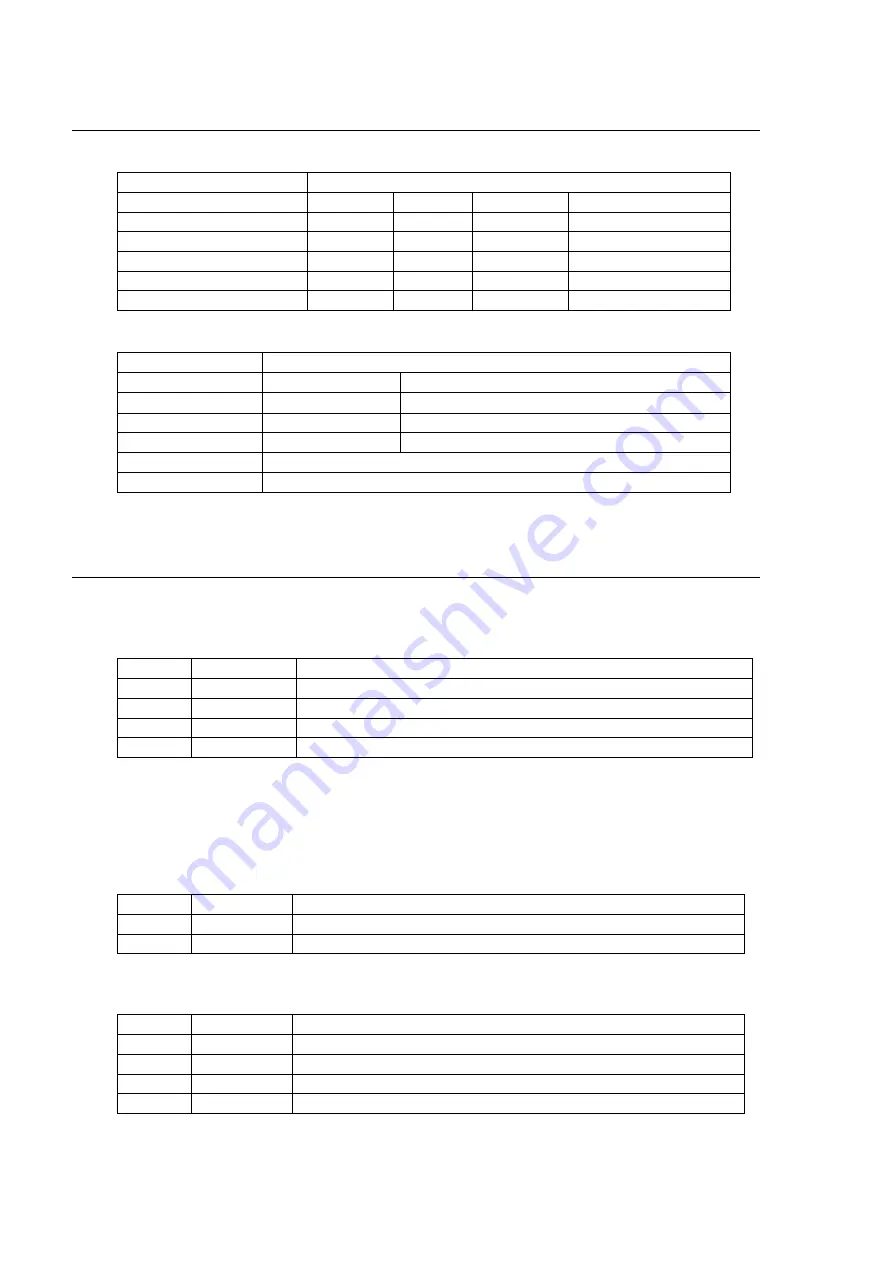

Electrical Specifications (T = 25

C)

Parameters

Min

Typical

Max

Remark

Peak Output Current

1.0A

By User 4.0A

By DIP Switch

Supply Voltage (DC)

+20V

+36V

+50V

Logic Signal Current

6mA

10mA

30mA

Pulse Input Frequency

0

By User 200 kHz

Minimum Pulse Rate

2.5µs

Operating Environment and Parameters

Coolant

Natural Cooling or forced ventilation / heatsink

Environment

Space

Avoid dust, oil, frost and corrosive gases

Temperature

0

C to 50ºC

Humidity

40% to 90%RH

Vibration

5.9m/s

2

Max

Storage Temp.

-20 ºC to +65ºC

Weight

Approx 300g

3. DRIVER CONNECTORS, P1, P2 and P3

The following is a brief description of the two connectors of the Driver.

Control Signal Connector P1 Pins

Pin No.

Signal

Functions

1

Pulse +

Connect to +5v dc

2

Pulse -

Triggers motor to move

3

Dir

Connect to +5v dc

4

Direction -

Triggers change in direction of rotation

Please note motion direction is also related to motor-drive wiring. Changing the

connection of two-wires for a coil to the drive will also reverse motion direction.

SW4 OFF for Pulse and Direction and On for CW/CCW operation.

Power Connector P2 Pins

Pin No.

Signal

Functions

5

Connect to +5 vdc

6

Enable -

Connect to 0v to disable drive

Power Connector P3 Pins

Pin No.

Signal

Functions

7

Ground

Negative Power Supply 0v

8

VCC

Power 20V to +50V dc

9, 10

Phase A

Motor coil A (leads A+ and A-)

11, 12

Phase B

Motor coil B (leads B+ and B-)

Page 2