Operating Instructions for Ascoline 700, AGH 2xx, 4xx, 6xx

ascobloc

Gastro-Gerätebau GmbH

D-01156 Dresden, Grüner Weg 29

Germany

Tel. +49 351 4533-0

Fax: +49 351 4537-339

E-mail:

AGH2XX.doc, Status: 23.05.2013

Subject to change without notice!

5

4.2 Connections

Details of connections for the media can be taken from the accompanying connection diagram and

equipment description. Check whether the size and position of the electrical connections of the customer

side correspond to the information in the connection plan, equipment description or installation plan

The terminal box for the connections is located behind the front panel A (see data sheet). Make the

connections as shown in the annex or in the connection diagram accompanying the equipment. The

number of the connection diagram is to be found on the type plate. Once the electrical connections have

been made, close the cover of the terminal box and screw the front panel in place again

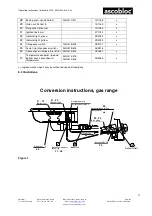

Gas type, connection pressure

The type of gas and the supply pressure must match the gas setting given on the appliance. If not, a

conversion or adaptation of the appliance must be made to suit the local conditions (see conversion

instructions).

Local gas conditions

You can get the necessary technical data about the type of gas and its pressure from your gas supply

utility.

Extraction of flue gas

Gas ranges are of Type “A”, i.e. the connection to a flue gas system is not required.

Ventilation of the rooms where the appliances are set up has to comply with the regulatory guidelines in

the DVGW Worksheet G 634.

4.2.1 Free-standing appliances

The connections can be made from below or from the rear from a closed installation space. With the

connection from below, the pipe length must be 50 mm above the floor surface.

4.2.2 Wall/table mounted appliance - attached to an installation wall, cantilever or wall-mounted

frame

When attaching the appliance to an installation wall, cantilever or on a wall-mounted frame (ACC 881),

the appliance connections from below or from the rear are to be used.

4.2.3 Wall/table-top appliances connect through the rear wall

On the right side at the rear in the corner is a bracket that is screwed on with downwards penetration that

covers the access to the installation channel to the rear. Remove the bracket, turn it through 180° and

screw it back on so that the penetration in the bracket now frees up access to the rear and covers the

downwards access.

5 Proper Use of the Equipment

5.1 Operational start-up

•

Remove the protective film before bringing into operation.

•

Clean the equipment with dilute soap solution.

•

Open the gas supply valve on the customer side.

5.2 Functional test

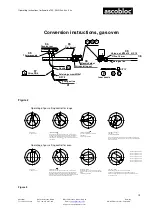

5.2.1 Gas range

Check that the burner cover is correctly seated.

Check the supply pressure (flow pressure): Connect the pressure gauge to the pressure measuring

nipple of the main gas pipe.

Bring the burners into operation and check whether the allowable supply pressure is maintained.

Check whether the nozzles appropriate to the gas supply have been installed (see conversion

instructions). Close the sealing screw of the pressure measuring nipple again once the measuring is

finished!

Bring all burners into operation. There is air in the lines prior to the first ignition so it takes somewhat

longer till the pilot flames can be ignited.

Check for ignition from the pilot to the main burner, through-ignition and a regular flame pattern.