Always assume that the tool contains fasteners.

Careless handling of the tool can result in unexpected

firing of fasteners and personal injury.

Do not point the tool towards yourself or

anyone nearby.

Unexpected triggering will discharge

the fastener, and can cause an injury.

Do not actuate the tool unless the tool is placed

firmly against the workpiece.

If the tool is not in

contact with the workpiece, the fastener may be deflected

away from your target.

Disconnect the tool from the power source

when the fastener jams in the tool.

While removing a jammed fastener, the tool may

be accidentally activated if it is plugged in.

Use caution while removing a jammed fastener.

Point the tool away from self and others.

The mechanism may be under compression and the

fastener may be forcefully discharged while attempting

to free a jammed condition.

Do not use this tool for fastening electrical

cables.

It is not designed for electric cable installation

and may damage the insulation of electric cables, thereby

causing electric shock or fire hazards.

TOOL SAFETY WARNINGS

1.

Hold tool by insulated gripping surfaces when

performing an operation where the tool may

contact hidden wiring or its own cord.

Contact with a “live” wire will also make exposed metal

parts of the tool “live” and can shock the operator.

2.

Know your power tool.

Read operator’s manual

carefully. Learn its applications and limitations, as well

as the specific potential hazards related to this tool.

Following this rule may reduce the risk of electric shock,

fire, or serious injury.

3.

Always wear safety glasses with side shields.

Everyday glasses have only impact resistant lenses.

They are NOT safety glasses. Following this rule may

reduce the risk of eye injury.

4.

Protect your hearing.

Wear hearing protection during

extended periods of operation. Following this rule may

reduce the risk of serious personal injury.

5.

Protect your lungs. Wear a face or dust mask if

the operation is dusty.

Following this rule may reduce

the risk of serious personal injury.

6.

Do not attempt to alter the tool.

Your T50AC

™

has a tested cycling time. It is designed to perform

adequately at this rate. Any unauthorized alteration

and/or use could result in a hazardous condition causing

possible serious personal injury. Unauthorized parts

and/or tool modification automatically voids warranty.

7.

The tool should always be supplied via

CLASS A residual current device (GFCI)

SPECIFIC SAFETY RULES

6

7

FUNCTIONAL DESCRIPTION

V ...................... Volts

A ...................... Amperes

Hz .................... Hertz

- ...................... Alternating Current

Obey all safety messages that follow this

symbol to avoid possible injury or death.

To avoid loss of hearing, always wear

ear protection when operating the tool.

To avoid eye injury always

wear safety glasses when

operating the tool.

Class II Tool

DEFINITION OF SYMBOLS USED ON TOOL

& FUNCTIONAL DESCRIPTION

SPECIFIC WARNINGS & SAFETY RULES

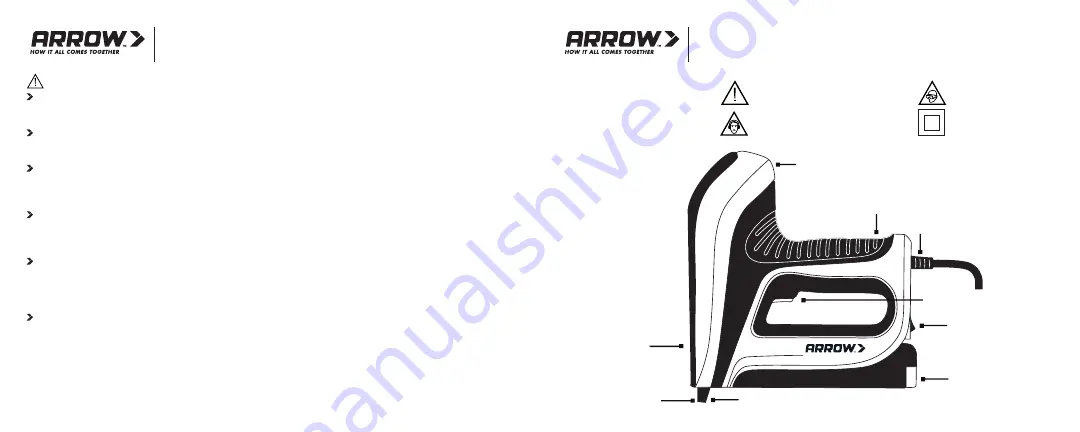

On/off switch

Low staple/nail indicator light

Soft overmold grip

Power cord

Quick release

magazine

Trigger

Moter Drive

Technology

Contact safety

LED

work light