Armfield Instruction Manual

22

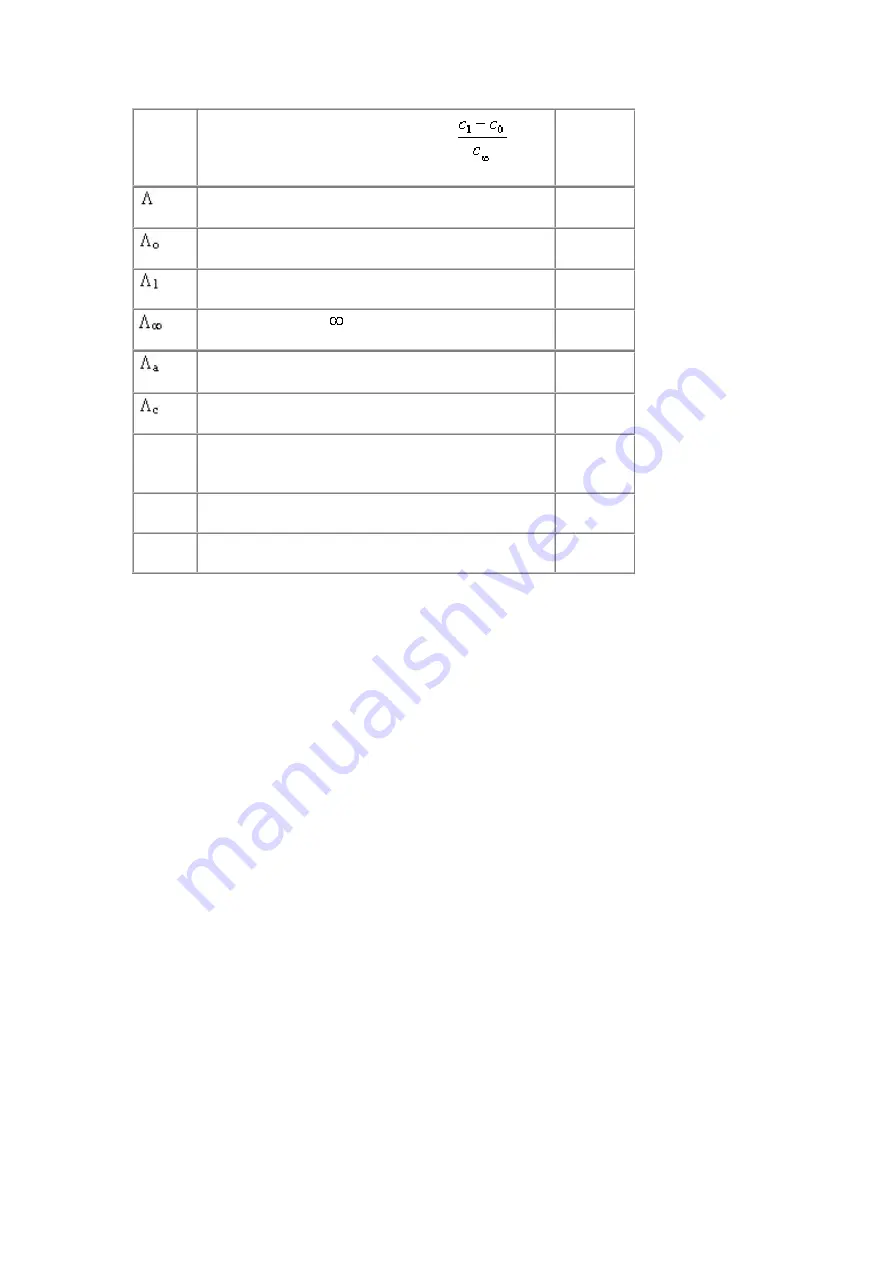

X

c

conversion to sodium acetate =

conductivity (Siemens/cm)

initial conductivity

conductivity at time t

conductivity after time

sodium hydroxide conductivity

sodium acetate conductivity

C

concentration in reactor at time

t

after input step

change

C

0

concentration of the input

t

c

time constant

Common Theory

The Armfield continuous stirred tank reactor is designed to demonstrate the

mechanism of a chemical reaction in this type of reactor as well as the effects of

varying the process conditions such as reaction temperature, reactor volume, stirring

rate, feed rate etc.

The reactor volume can be varied by adjusting the height of the internal standpipe.

The actual volume must be checked by filling the reactor with water to the overflow

then draining the reactor contents into a measuring cylinder.

The conductivity of the reacting solution in the reactor changes with the degree of

conversion and this provides a convenient method for monitoring the progress of the

reaction either manually or by computer.

The reaction chosen is the saponification of ethyl acetate by sodium hydroxide as it

can be carried out under safe conditions of temperature and pressure and is well

documented.

The experiments involve the collection and storage of conductivity data. The USB

port located at the front of the Service Unit must be connected to the computer. This

will enable data logging of the conductivity and temperature sensor at selected time

intervals over a selected period of time.

Although it may be possible to carry out demonstrations using other chemicals, it is

not advisable as the materials of construction of the reactor may not be compatible.

As the standard reaction is exothermic the heat generated by the reaction will result

in a rise in temperature of the vessel contents that is unavoidable. If it is required to