Subject to change · UMPC 045_31168300 · 0717 · EN

Page 38

www.argo-hytos.com

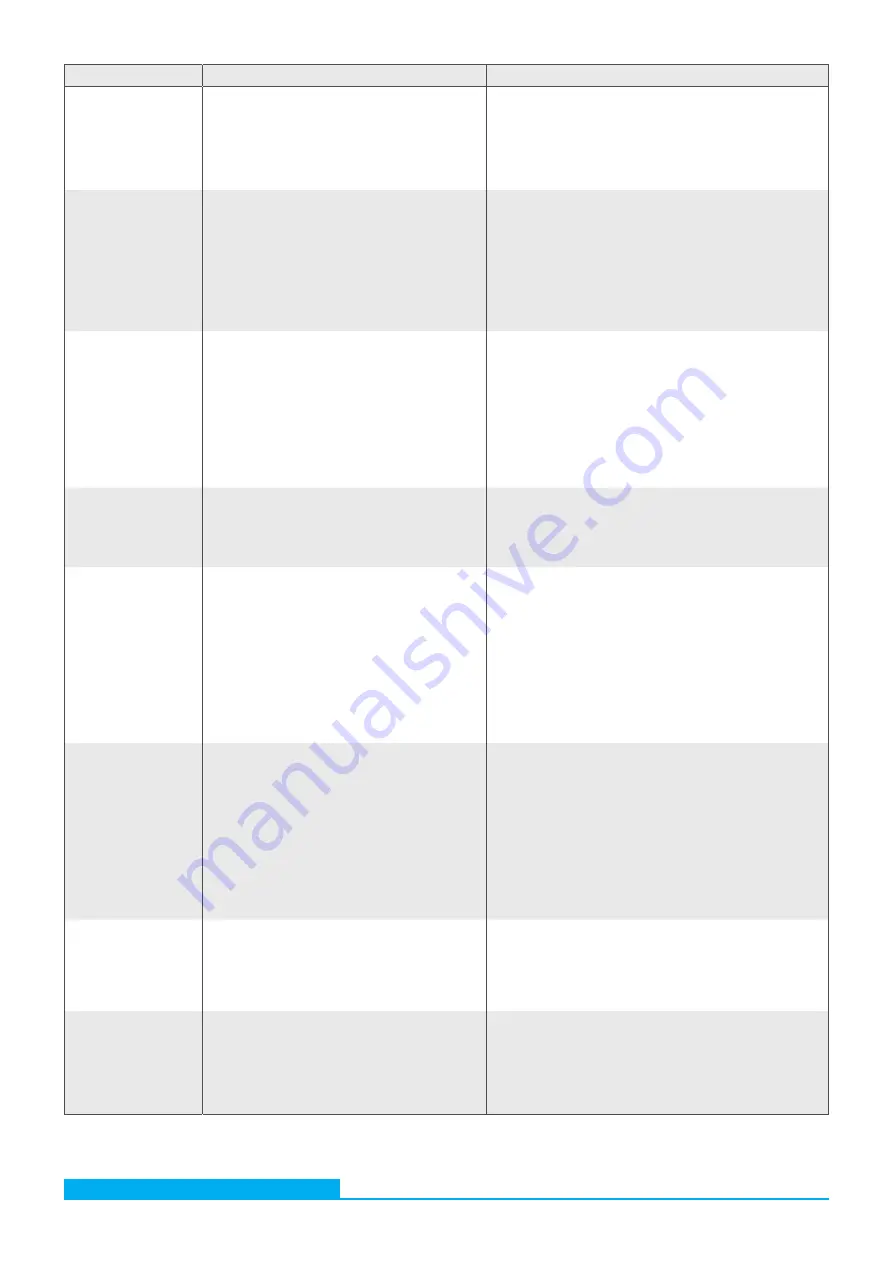

Error

Reason

Measure

E-motor can not be

switched on during

commissioning

›

E-cable or plug defective

›

Missing mains voltage

›

Motor defective

›

Pump defective

›

Too high viscosity (medium)

›

Have the cables disconnected by qualified personnel

›

Establish power supply / activate electrical fuse

›

Replace motor (repair at manufacturer)

›

Replace pump (repair at manufacturer)

›

Heat medium

E-motor switches off

during operation

›

Filter element contaminated

›

Suction strainer contaminated

›

Viscosity too high

›

Suction height too great

›

Leakage on the suction side

›

Wear of the pump

›

Replace filter element

›

Replace the suction strainer

›

Heat medium

›

Adjust suction height

›

Replace the suction hose or seal the connection points

(retighten them)

›

Replace pump (repair at manufacturer)

Too loud operating

noise

›

Filter element contaminated

›

Suction strainer contaminated

›

Viscosity too high

›

Suction height too great

›

Leakage on the suction side

›

Filter unit is mounted on a vibration-sensitive

base (sheet metal)

›

Replace filter element

›

Replace the suction strainer

›

Heat medium

›

Adjust suction height

›

Replace the suction hose or seal the connection points

(retighten them)

›

Improve your local conditions

Pump does not suck

›

Leakage on the suction side

›

Sealing plug of the screen element is leaking

›

Unit is pumped empty (when refilling)

›

Replace the suction hose or seal the connection points

(retighten them)

›

Check / replace sealing ring, check tightening torque

›

Prime the unit (0.5 l to 3 l)

Cleanliness classes

displayed on the

LubMon Visu do not

change during

cleaning

›

Max. dirt capacity of the filter element is

reached

›

Leakage at the suction hose, falsification of

the measurement results by free air in the oil

(air bubbles)

›

Rotary valve on lever position "Pumping"

›

Replace filter element

›

Check the suction connection, if necessary, tighten the

hose clips / check the oil for foaming or air bubbles and

eliminate the cause.

If the cause cannot be eliminated, take the oil sample

and have it evaluated in the laboratory. Vent the filter

unit

›

No particle counting is possible with the lever position

"Pumping"

Cleanliness classes

displayed on the

LubMon Visu become

poorer during

cleaning

›

Max. dirt capacity of the filter element is

reached

›

Leakage at the suction hose, falsification of

the measurement results by free air in the oil

(air bubbles)

›

Rotary valve on lever position "Pumping"

›

Replace filter element

›

Check the suction connection, if necessary, tighten the

hose clips / check the oil for foaming or air bubbles and

eliminate the cause.

If the cause cannot be eliminated, take the oil sample

and have it evaluated in the laboratory. Vent the filter

unit

›

No particle counting is possible with the lever position

"Pumping"

Displayed cleanliness

classes are not

plausible

›

Viscosity range below or exceeded. Particle

counter is supplied with too little or too

much oil

›

Rotary valve on lever position "Pumping"

›

Adjust the fluid temperature (also see operating

conditions)

›

No particle counting is possible with the lever position

"Pumping"

After cleaning for

high cleanliness

classes no further

improvement (e.g.

order number 10 at

4, 6 and 14 μm).

›

Set measuring time is too short

›

Observe the defined limit values for oils with

cleanliness classes according to ISO 4406.

Upper limit value: 24 (for 4, 6 and 14 µm)

Lower limit value: 10 (for 4, 6 and 14 µm)

Table 7: Error description