14

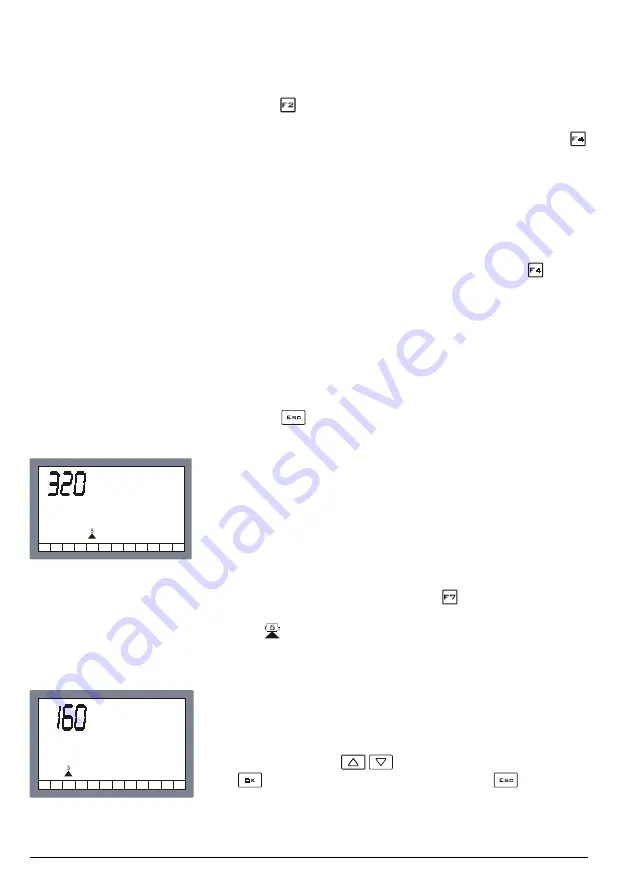

Fig.14:

Setting the tank filling level

Fig.15:

ISO11002 nozzle selection

Pressing the

keys sets the tank level at the maximum filling

level envisaged by the manufacturer.

To set a level different from the maximum filling value, press

so that the liquid in tank value flashes and use the modification

keys to change it.

Filling the tank by means of the flowmeter

So the computer stores the exact quantity of liquid put into the

tank, it is possible to fill the tank up with the specific flowmeter.

To do this, access the filling up menu by pressing the

key

on the main screen page until the screen page shown in Fig.

13 appears.

Now fill the tank up by starting the loading pump.

The computer shows in real time the quantity of liquid that has

been put inside the tank which is added to the liquid that is

already inside it, until the loading pump stops. (In the example

given in Fig. 13 there are 2,588 litres inside the tank).

Once filling up is finished, return to the main screen page by

pressing key

.

Selecting the nozzle

The user will have selected the nozzle to be used for the

treatment on the basis of the speed at which the treatment is to

be performed and the quantity of liquid per hectare to be used.

This information is fundamental if using a pressure transducer

to regulate the distribution, but with a flow-meter alone, it is

only used to correct display of the pressure value calculated by

the computer (it does not affect the distribution setting).

Nozzle setting is begun by pressing the

function key for one

second, until the screen shown in fig14 appears.

A flashing

symbol appears in the bottom of the screen,

indicating the type of nozzle selected (in the example, number

5).

The flashing symbol is underneath coloured indicators repre-

senting the standard ISO nozzle colours.

If the nozzle chosen is ISO, e.g. ISO11002 (yellow), simply

bring the flashing symbol above the rectangle of the same

colour (yellow) with the

keys.

Press

to confirm the new nozzle and exit or

to abort.