MAINTENANCE MANUAL

AQUILA AT01

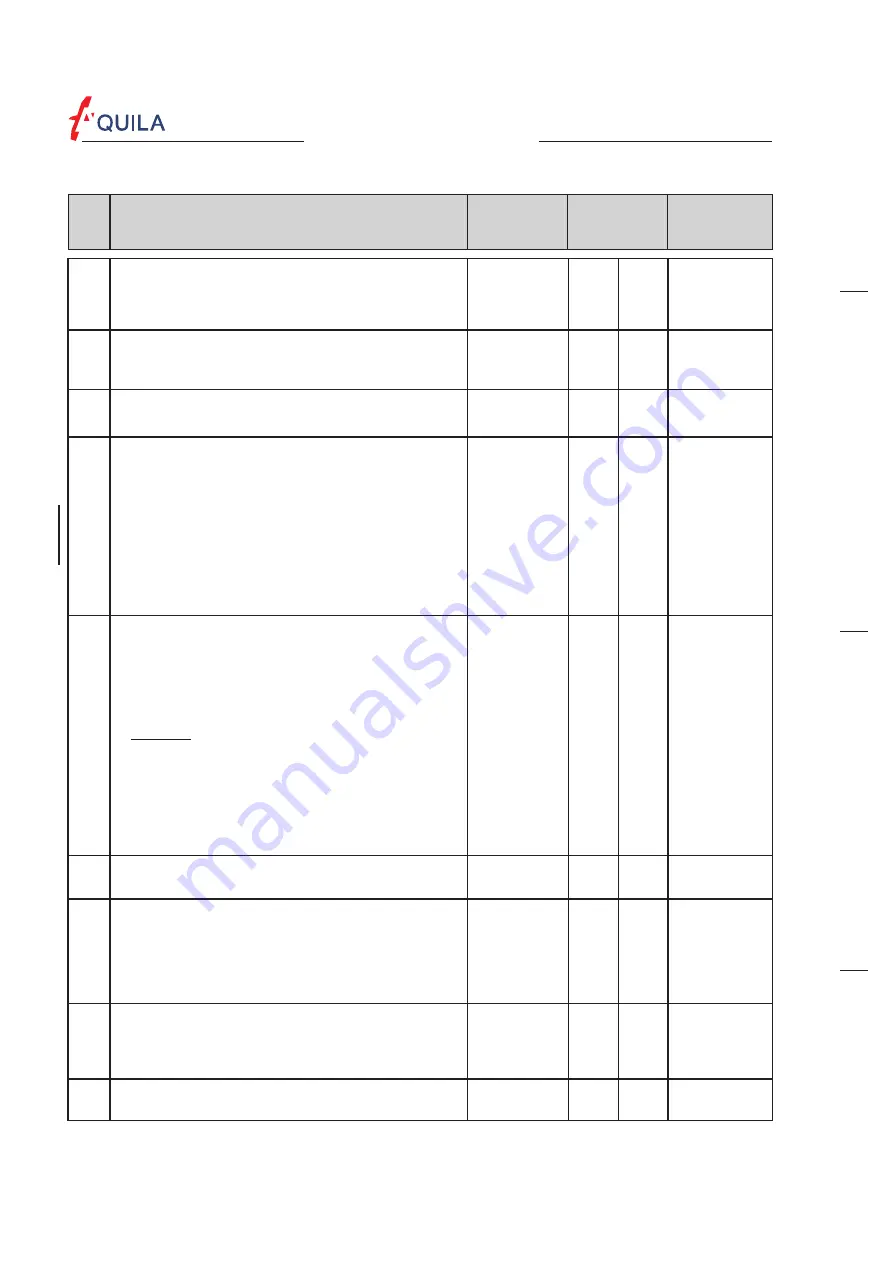

A

1.

Engine cowling - Remove engine cowling. Check for cracks,

X

overheated areas, deformation, loose or missing fasteners.

Check condition of fire protect paint and heat resistance

shielding.

2)

1)

2.

Engine oil change - Remove oil drain screw from oil tank.

12-12-00

X

50h

Drain old oil and dispose in accordance with environmental

R912* 12-20-00 11)

regulations.

1)

3.

Oil tank - Check oil tank and clean if contaminated.

R912* 12-20-00 11)

X

200h

2)

1)

4.

Oil filter - Remove old oil filter from engine and install new

12-12-00

X

50h

oil filter. Lubricate mating sealing ring of new oil filter with

R912* 12-20-00 11)

engine oil. Tighten new oil filter by hand.

Cut open old oil filter without producing any metal chips and

inspect filter mat, filter cover, sealing lip, spring of bypass

valve (small) and positioning spring (large) for particles, wear

and missing material.

Findings:_____________________

2)

1)

5.

Oil change - Renew gasket ring of drain screw on oil tank.

12-12-00

X

50h

Tighten drain screw to 25 Nm (221 in.lbs).

R912* 12-10-00 4)

Refill oil tank with approx. 3 liters of oil. For oil quality, see

R912* 12-20-00 11)

Operators Manual and SI-912-016.

SI-912-010

SB-912-040

Refilled:______________Quantity:_______L

CAUTION:

DO NOT USE AIRCRAFT ENGINE OIL.

Due to the friction clutch and the high stresses

in the reduction gear 4-stroke motor cycle oils are

recommended. For suitable lubricants and oil change

intervals, see ROTAX Operators Manual and latest

appropriate ROTAX publications.

2)

1)

6.

Visual inspection of the magnetic plug for accumulation

R912* 12-20-00 12)

X

50h

of chips

7.

Check compression by differential pressure method.

R912* 12-20-00 5)

200h

Test pressure: 6 bar (appr. 6000 hPa / 87 psi)

Pressure drop: max. 25%

Cyl. 1 2 3 4

Pressure drop: _____ _____ _____ _____

2)

8.

Cooling air ducts, engine baffling and cylinder cooling

R912* 12-20-00 3)

X

fins - Check for obstructions, cracks, wear and general

SB-912-029

condition. Check for signs of abnormal temperatures.

Check crankcase for cracks.

2)

9.

Leakage bore at the base of the water pump - Check for

R912* 12-20-00 4)

X

signs of leakage.

Page 4

05-20-00

Maintenance Checks

No.

Engine

Reference

Interval

Initials

100h

other

1) If more than 30% of operation hours have been flown with leaded fuel e.g.: AVGAS 100LL

2) Check has to be carried out every 100 hours of operation or 12 month, whichever comes first.

16.09.19

Summary of Contents for AT01

Page 2: ...MAINTENANCE MANUAL AQUILA AT01 A ...

Page 4: ...MAINTENANCE MANUAL AQUILA AT01 A ...

Page 6: ...MAINTENANCE MANUAL AQUILA AT01 A ...

Page 9: ...MAINTENANCE MANUAL AQUILA AT01 A CHAPTER 5 TIME LIMITS MAINTENANCE CHECKS ...

Page 10: ...MAINTENANCE MANUAL AQUILA AT01 A ...

Page 12: ...MAINTENANCE MANUAL AQUILA AT01 A ...

Page 14: ...MAINTENANCE MANUAL AQUILA AT01 A ...

Page 18: ...MAINTENANCE MANUAL AQUILA AT01 A Maintenance Checks ...

Page 46: ...MAINTENANCE MANUAL AQUILA AT01 A Maintenance Checks ...