WAFER PATTERN CHECK VALVES - ‘SLP’ & ‘SW’ STYLE

Australian Pipeline Valve - Installation, Operation and Maintenance Manual

10

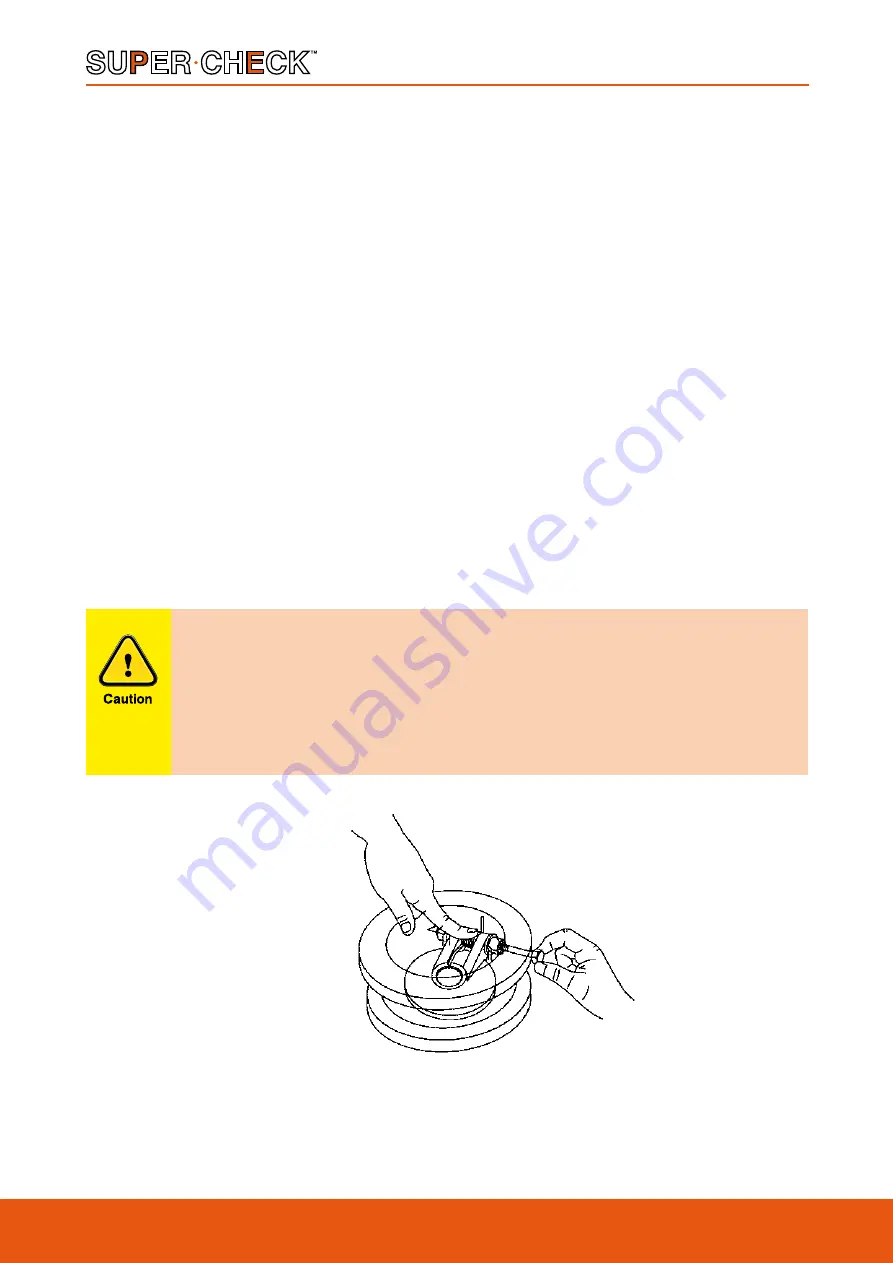

Important see Diagram 5 and caution note below about guarding the spring during disassembly to

prevent eye damage. Refer to exploded view in Appendix.

5.4 ASSEMBLY SLP SERIES

a) Lay the body (1) down, with ‘downstream’ side of the body facing upward. Lay disc (2) inside the body

(1). Slide hinge pin (3) into the body through the bushings (6) (where fitted) the spring (5) and disc (2).

Refer paragraph b) below on energising spring into the body. Reinsert disc into body cavity with shaft

holes inline with side shaft port. Slide shaft into the body through shaft bearing on one side. Continue

sliding shaft through disc, disc spring and remaining bushing. Check the disc (2) and bushings for end

play. If body plate is severely worn it should be replaced.

b) Wind the spring (5) 180° in a clockwise direction. Place the wound spring (5) in position between the

disc hinge lugs ensuring the long convex side of the spring’s leg is against the disc, the other end must

be energised against the wall of the valve as per the Diagram 4. Different sizes and classes may have

different spring configurations. While maintaining pressure on the spring (5), insert the hinge pin (3)

into the body (1) passing it through the bushings (6) (where required), disc (2) and spring (5) as detailed

above in paragraph a).

c) Teflon tape the threads of the hinge pin retainer, and screw the hinge pin retainers (8) into the body (1).

After repair, the valve should be retested as per API 598 or applicable standard.

DIAGRAM 5

For SLP and SW series: under no circumstances wind springs to gain a higher or

lower torsional load. Special high and low torque springs are available for this

purpose. Before attempting shaft extraction, be sure to press hand over the disc

spring (see Diagram 5). Failure to do this may result in personal injury due to the

spring “launching” itself unexpectedly once the shaft is pulled free of it. Always

wear protective eyewear.