WAFER PATTERN CHECK VALVES - ‘SLP’ & ‘SW’ STYLE

Australian Pipeline Valve - Installation, Operation and Maintenance Manual

8

2.9 GASKETS

The opening end of the outlet side of Single Flap Check valve is manufactured larger than the internal

diameter of the pipe. Use a gasket that is either the same internal diameter of the Uni-Check outlet, or

slightly larger. Most common spiral wound or CNAF pipe gaskets will fit, providing they are the same

corresponding flange class rating as the valve it’s specified to. CNAF gaskets are only suitable up to 1400

kPa (200 PSI). Ring joint gaskets are frequently specified for class 900 to 2500. The recommended

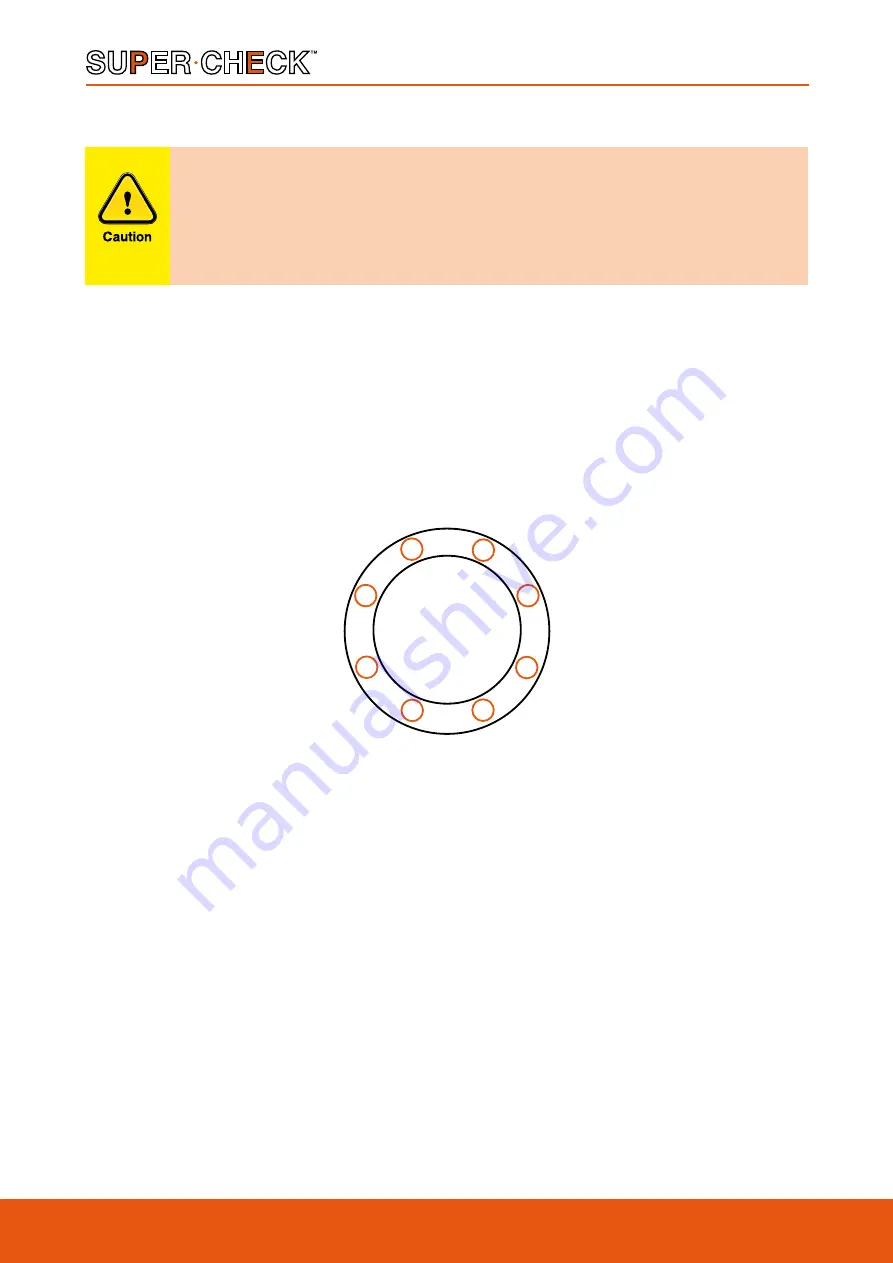

tightening sequence is shown below in Diagram 4. Tighten in numerical order, gradually increasing torque

with each sequence.

2.10 POST-INSTALLATION PROCEDURES

After installation, the line should be cleaned by flushing to remove any foreign material. When caustics

are to be used to flush the line, additional flushing with clean water is required. The valve should be

opened and closed after installation to ensure proper operating function.

With the line pressurised, check the valve end connections and any body plugs for leaks.

3 . 0 O P E R A T I O N

The check valve operation is automatic and requires no assistance. When the flow exerts sufficient

pressure against the disc to overcome the disc’s weight, the disc allows the flow to continue through the

piping system. As pressure decreases, the disc lowers until it’s own weight forces it to seat. This prevents

the possibility of a reversal in the flow. Metal seated check valves are not zero leak devices and may

Wafer check valves are designed for steady flow conditions and are not

recommended for use near reciprocating pumps, but especially compressors, any

pulsating devices or other types of physical/thermal shock-load applications. In this

type of application, the check valve will not perform efficiently and will ultimately

fail.

3

8

2

5

4

7

1

6

ORDER OF TIGHTENING BOLTS

DIAGRAM 4