- 8 -

ENGLISH

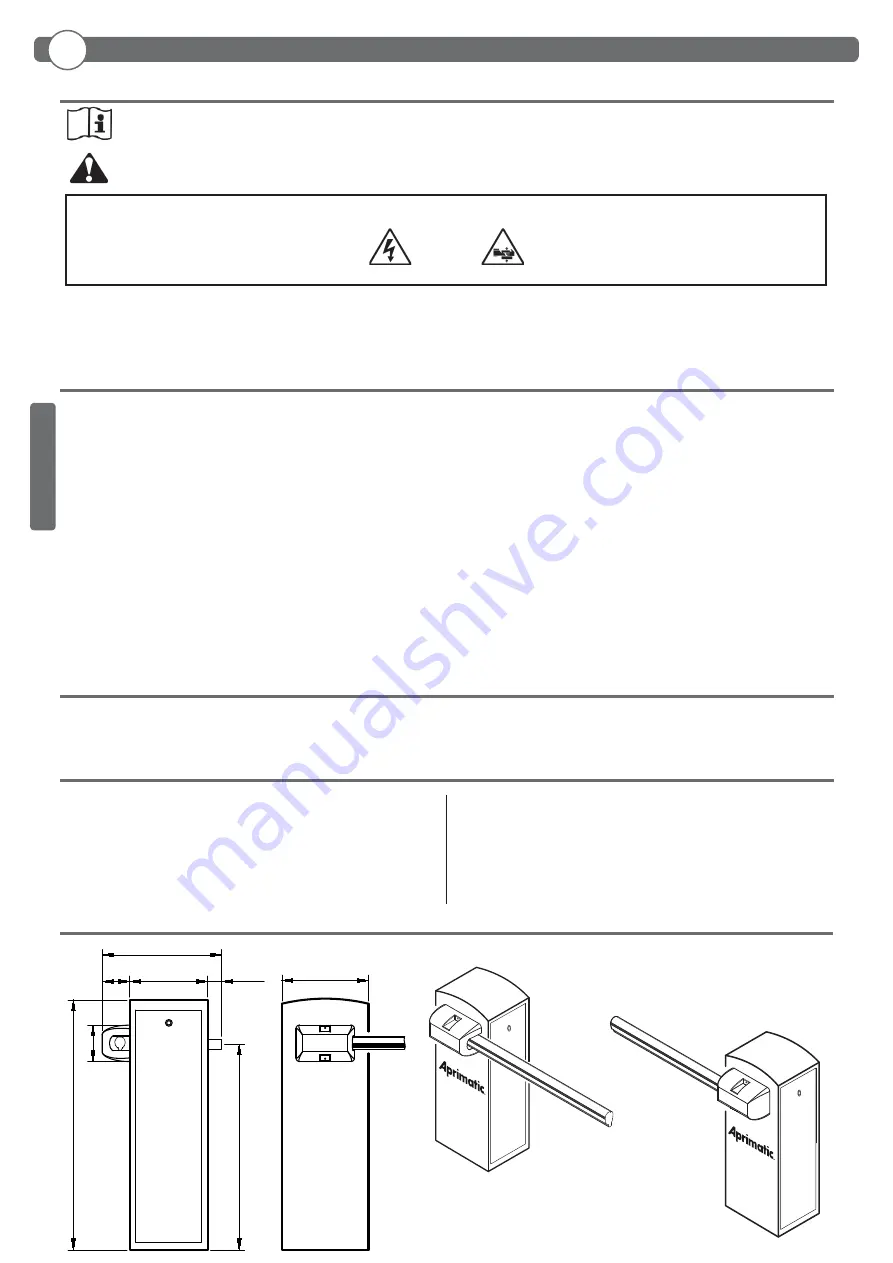

1.5 OVERALL DIMENSIONS

1.1 INTRODUCTION

Please read it carefully before installing the appliance, before using it and before routine or extraordinary maintenance work.

The notices preceded by this symbol provide important information, the non-compliance with such instructions voids the

manufacturer’s guarantee.

OPERATIONS THAT, IF NOT CARRIED OUT CORRECTLY, CAN BE RISKY, ARE INDICATED WITH THE FOLLOWING SYMBOLS:

ELECTROCUTION

CRUSHING

The INSTALLATION, USE AND MAINTENANCE handbook is for installers, users and maintenance engineers

The Company is not liable for injury to people or animals or damage to things in the case of applications that exceed the limits

specifi

ed

on the enclosed technical data sheet or by a use

diff

erent from what the appliance has been designed.

1.2 GENERAL SAFETY

• Scrap packing materials (plastic, cardboard, polystyrene etc) according to the provisions set out by current standards. Keep nylon or polystyrene

bags out of children’s reach.

• The Company declines all responsibility for any consequences resulting from improper use of the product, or use which is

diff

erent from that

expected and specifi

ed in the present documentation.

• Do not install the product in explosive atmosphere.

• Disconnect the electrical power supply before carrying out any work on the installation. Also disconnect any

buff

er batteries, if fi

tted.

• Fit an omnipolar or magnetothermal switch on the mains power supply, having a contact opening distance equal to or greater than 3,5 mm.

• Check that a

diff

erential switch with a 0,03A threshold is fi

tted just before the power supply mains.

• Fit all the safety devices (photocells, electric edges etc.) which are needed to protect the area from any danger caused by squashing, conveying

and shearing, according to and in compliance with the applicable directives and technical standards.

• The Company declines all responsibility with respect to the automation safety and correct operation when other manufacturer’s components are

used.

• Only use original parts for any maintenance or repair operation.

• Do not modify the automation components, unless explicitly authorised by the Company.

• Instruct the product user about the control systems provided and the manual opening operation in case of emergency.

• Do not allow persons or children to remain in the automation operation area.

• Keep radio control or other control devices out of children’s reach, in order to avoid unintentional automation activation.

• Anything which is not expressly provided for in the present instructions, is not allowed.

1.3 GENERAL

The automatic electromechanical barrier is designed to control passage openings up to 3 metres wide in compliance with European standards. It is

suitable for industrial applications and it is the ideal solution for managing vehicle

traffi

c.

1.4 TECHNICAL SPECIFICATION

Power .............................................................................................

230

Vac ±

10

%

50/60

Hz

Motor 230Vac ..........................................................................

1.400

RPM

16

uF

0,27

kW

Absorbed power ...........................................................................................................

300

W

Control unit ...........................................................................................

TRAFFIC PARK 230

Impact safety ............................................................................................................. Reverser

Opening time .....................................................................................................................

1,7

s

Arm length ...............................................................................................................

1,7

÷

3

m

Working temp ..............................................................................................

-30 *** +60

°C

Manoeuvres in 24h ....................................................................................................

10 000

Protection level ...............................................................................................................

IP 54

Net weight........................................................................................................................

60

kg

Gross weight ....................................................................................................................

62

kg

***

With integrated heater active

1. General information

EN

400

360

950

5

47

60

1155

168

127

RIGHT

barrier

LEFT

barrier

Summary of Contents for PARK 30 PLUS

Page 2: ......

Page 25: ...25...

Page 27: ...27...

Page 28: ...INSTALLATORE INSTALLER INSTALLATEUR INSTALLATEUR INSTALADOR...