4

803809 Rev. 01

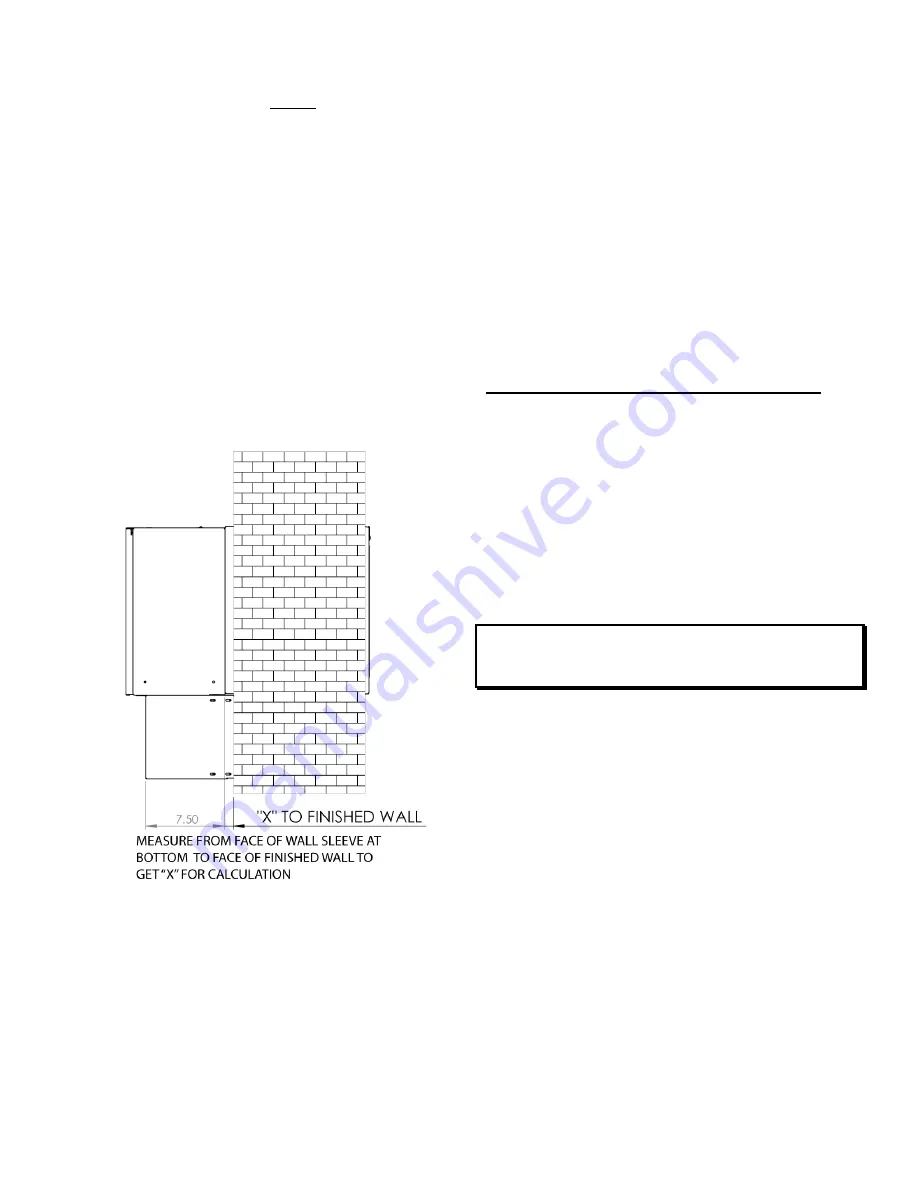

Adjust the side flanges as follows:

Measure the penetration of the bottom of the wall

sleeve into the room relative to the finished wall

surface, and record as “x”. Remove the grille cover

from the heating subbase by rotating the two ¼ turn

finger and thumb fasteners until the grille cover

releases. The total side length of the heating subbase

(cover removed) plus side channel closure is calculated

as 7.5 + “x”. Insert the side channels and secure with

the screws provided, set at the total side length

calculated. Center the subbase under the wall sleeve

opening and adjust the levelling feet to the anticipated

correct height. Final height adjustment can be made

after the wall sleeve is permanently installed. At that

point, the flanges of the side channels can be screwed

to the finished wall from inside the subbase if desired,

to anchor the entire heating subbase assembly in place.

The bottom of the wall sleeve will end up overlapping

the subbase by about 0.875 inches.

Plumbing Connections:

The heating coil is supplied with 5/8” O.D. (actual

diameter) copper tubing connections. Hot water heating

typically requires a Normally Open (NO) water valve, and

steam usually requires a Normally Closed (NC) steam

valve. The NFWC unit 24 VAC control output to the

valve is factory set for NC but can be field-converted to

NO duty as described in Section

Heating/Cooling Chassis

Installation.

Remove the cover plate on the right hand side of the

heating coil to provide better access to the copper

connection tubes. Always pipe the valve to the supply

connection. If the heating medium is hot water, connect

the valve “outlet” (Supply) to the lower connection and

the Return water to the upper connection. If the heating

medium is steam, connect the valve “outlet” (Supply) to

the upper connection and the Return to the lower

connection. Route the steam or water source to the valve’s

“inlet” connection.

Install the piping, valve, and accessories (as specified by

the design engineer) in the space available under the

heating coil.

ELECTRICAL WIRING AND RECEPTACLE

Wire Sizing

A single outlet branch circuit from the main electrical

panel to the receptacle in the subbase should be used.

Wire sizing shall be in accordance with the minimum

circuit ampacity as declared on the unit Rating Plate for

the specific chassis. Wire sizing must also take into

account any distance from fuse box or breaker panel to

receptacle to prevent excessive voltage drop in

undersized wires.

IMPORTANT:

Low voltage to the unit will cause

compressor starting problems and decrease the

performance and reliability of the compressor.

Branch Circuit Protection

The Current Rating of branch circuit protection using a

Time Delay Fuse or HACR circuit breaker should also

be as declared on the unit Rating Plate for the specific

chassis being installed.

Plug and Receptacle

All 230-208 Volt units are normally furnished with a

NEMA 6-20P, 20 Amp non-locking plug, and hence

will require a NEMA 6-20R receptacle to be installed

in the heating subbase.

All 115 Volt units are furnished with a NEMA 5-15P,

or 5-20P non-locking plug as applicable. The

respective plug will require a NEMA 5-15R or

combination 5-20R receptacle to be installed in the

heating subbase.