6

803809 Rev. 01

6.

Locate the 24 Volt wiring harness either coiled

beneath the control box or shipped loose with the

unit. The harness is used to make connections to the

aquastat. It is also employed if a remote 24 Volt AC

wall thermostat will be used. Connect the multi-wire

24 volt wiring harness to the mating plug protruding

beneath the control box, as applicable, and follow the

detailed instructions on the wiring diagram affixed to

the specific unit being installed. Insulated crimp-on

connectors are provided at the end of every

connection lead to facilitate connections/insulation.

If

an aquastat will be not be used, you must connect

the ends (blue/orange) of the aquastat leads

together to permanently complete the aquastat

circuit.

7.

A 24 VAC water or steam valve output connector is

also provided under the control box. A mating

connector and 3 feet of wire leads are supplied to

connect to a 24 VAC valve. The units can

accommodate a normally-open NO or a normally-

closed NC valve. The NO/NC switch is located in the

high voltage wiring compartment as a DIP switch on

the electronic control board, and is factory set to NC.

The setting can be changed to NO in the field by

qualified service personnel.

WARNING:

The NO/NC conversion procedure

involves exposure to high voltage electrical circuits in

the control box in order to make the necessary change

to the DIP switch, and must be performed by qualified

service personnel. Failure to do so could result in

property damage, personal injury or death. Disconnect

electric power to the unit before servicing.

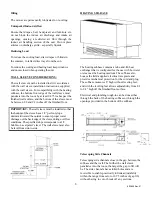

8.

Locate the indoor air thermistor bulb at the end of the

black thermistor wire with clamp coiled beneath the

control box. The bulb and clamp must be relocated to

the thermistor holder in the bottom of the heating

subbase so it is sure to sense true return air

temperature, and not air that has been heated by the

heating coil. Use the clamp provided to secure the

bulb in place.

IMPORTANT:

To avoid damaging the indoor

thermistor wire, always remove the thermistor from the

clamp holder before removing the chassis for service.

IMPORTANT:

Operating the unit without the filter in

place can damage the unit, and void the warranty.

Always remember to re-install the filter after servicing

the chassis, or replacing/cleaning the filters.

9.

Wipe unit cabinet/wall sleeve to remove dirt, etc.

10.

The unit is now ready for operation, when supplied

with power from the distribution panel and wired to a

remote thermostat (if applicable).

START-UP CHECKLIST

Note: Once the unit is installed, it should be checked

for proper function by qualified service personnel

before turning it over to the User.

Circuit breakers, wire size, and electrical

connections tight and correct

Filter clean and properly in place

Condenser air inlet and outlet free of

obstructions and no short-circuiting of

condenser air

Unit operated for 20 minutes to prove stability

Controls operation OK

Unit installed in compliance with all codes and

ordinances

All panels in place and secured with required

fasteners

Mylar overlay applied to cover up touch pad

for 24 Volt Remote Thermostat installations.

Work area clean and free of debris

Owner or operator instructed on control

operation and routine maintenance.

USER CONTROLS - GENERAL

NFWC series is available with advanced-function

electronic controls with membrane switch type keypad.

ELECTRONIC CONTROLS

The chassis incorporating electronic controls is factory-

shipped with an active keypad control and display

mounted directly to the control panel. The unit

functions are controlled by the user by pressing the

keys on the keypad, and reading the display. However,

the unit also has the latent ability to be field-converted