– 46 –

SECTION VII - TROUBLESHOOTING WITH DDC CONTROLS

continued

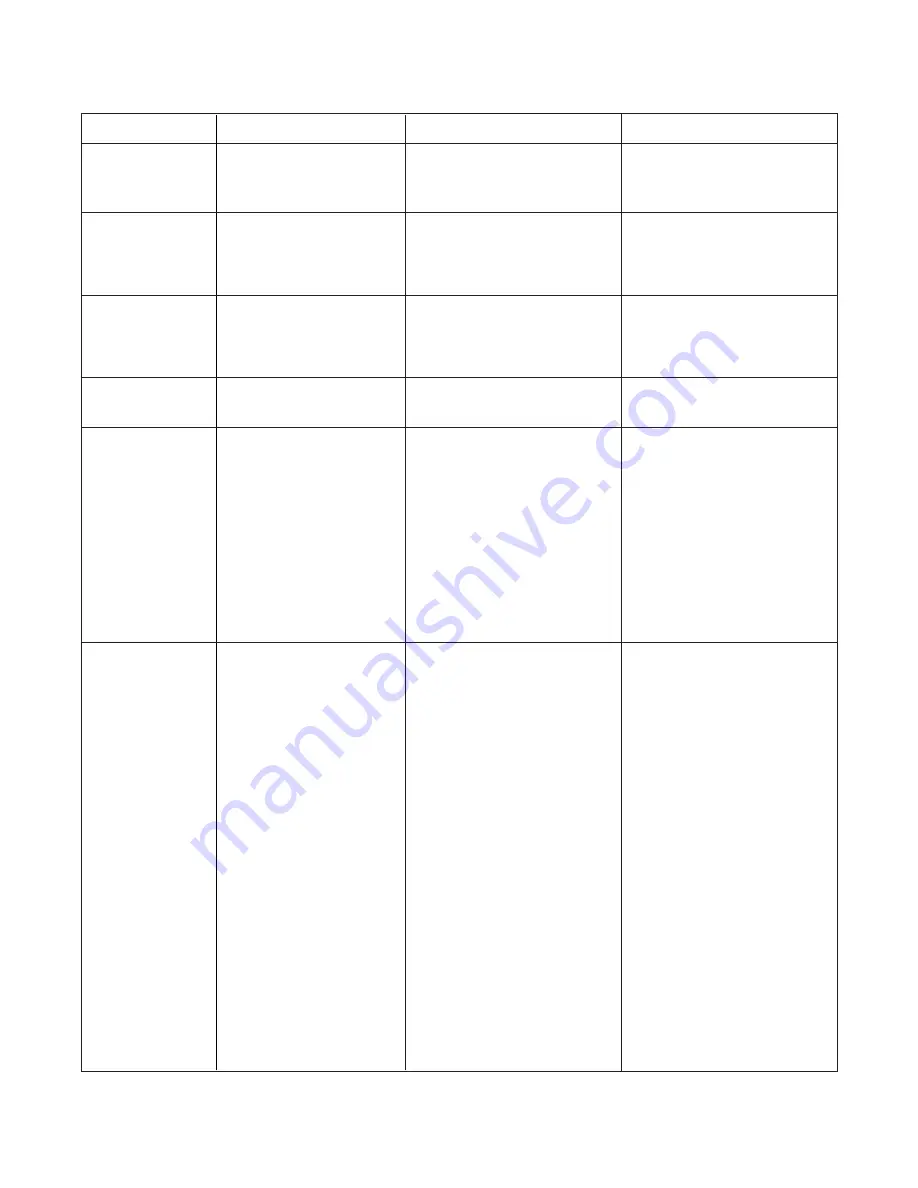

Modulating Room Temperature (MRT, MRT-PRO or MRT-EXPERT) Controls

Symptom

Possible Cause

Field Test

Remedy

1. Install properly.

1. Replace modulating gas

valve operator (MT-11) or

transformer.

1. See checkout procedure if

voltage is correct.

2. Consult factory.

1. Adjust to proper minimum

fi re.

1a. Replace Sensors if reading is

incorrect or correct wiring.

1b. Change to correct setpoint.

1c. Change to correct setpoint.

1. Change to correct setpoints.

A. No Gas Flow with

DO-2 on UC-01

energized.

B. Continuous Low

Fire (Electronics

OK).

C. Continuous Low

Fire (Electronics

Problem).

D. Incorrect

Minimum Fire.

E. Continuous

Minimum

Discharge Air

Temperature.

F. Incorrect

Maximum

or Minimum

Discharge Air

Temperature.

Control circuits external to MRT Controls can cause burner malfunction.

Always check manual valve to be certain gas is on, and check limit controls for normal operation.

1. Arrow on side or bottom

of valves should point in

direction of gas fl ow.

1. Inspect wiring (see check out

procedure in Section X).

1. Check for 2-10 VDC at input

terminals.

2. Check 0-10 VDC voltage on

AO-1.

1. See Butterfl y Valve Adjustment.

1a. Check Space Temperature

Sensor (TS-02), use a

BACview 6 to read TS-02

and Discharge Air Sensor

(TS-03) for correct readings.

See Thermistor curve.

1b. Check Space Temperature

Sensor (TS-02) and/or Unit

Enable Potentiometer (MP-15)

setpoint.

1c. Check Heating Occupied

and/or Unoccupied setpoint.

1. Install a BACview 6 or PC.

1. Gas valves improperly

installed.

1. Defective modulating

gas valve operator (MT-

11) and/or burned out

transformer.

1. Incorrect operation of

interface module (IM-02).

2. No output voltage on

UC-01.

1. Incorrect low fi re butterfl y

valve (GP-39) adjustment.

1. Incorrect room

temperature.

1. Maximum or minimum

heating discharge

temperature setpoint

not set correctly.

(Refer to Digital Control System User Manual for additional troubleshooting suggestions)

Summary of Contents for GAS-FIRED HEATERS

Page 6: ... 6 ...

Page 7: ... 7 ...

Page 8: ... 8 ...

Page 9: ... 9 ...

Page 13: ... 13 ...

Page 24: ... 24 TYPICAL SEQUENCE FOR MODULATING THERMOSTAT WITH 135 OHM CONTROLS ...

Page 25: ... 25 TYPICAL SEQUENCE FOR MODULATING THERMOSTAT WITH 4 20 mA CONTROLS ...

Page 64: ...4830 Transport Drive Dallas TX 75247 Phone 214 638 6010 Fax 214 905 0806 www appliedair com ...