15

35:

ctoP

upper correction

-4.00

÷

0.50

mA/V

changes

of0.05

mA/V

for 20mA or 10V

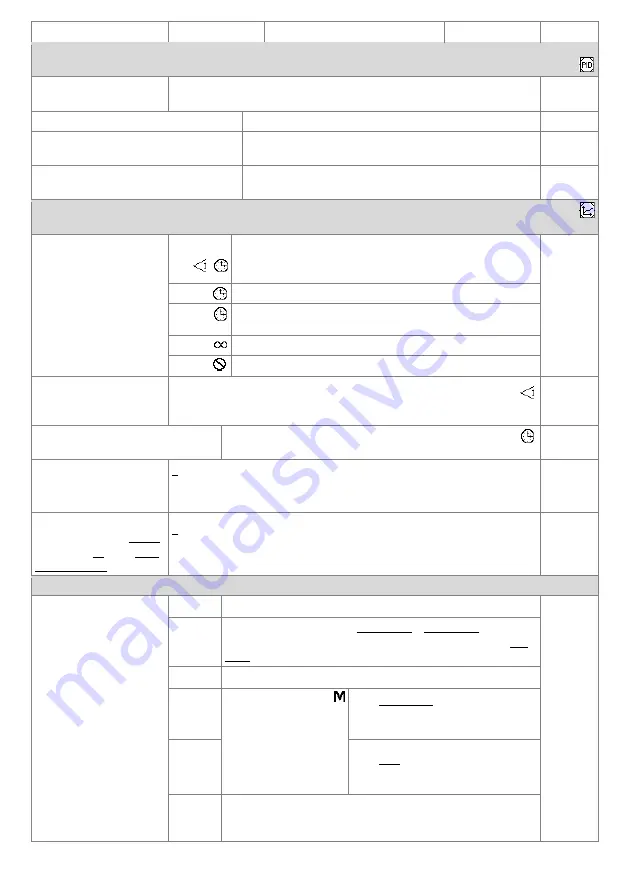

IV. PID ALGORITHM CONFIGURATION

(1÷3), submenu

Pid1

÷

Pid3

, in the 3 groups

Pid1

/

2

/

3

there are the same

parameter sets with different indices and numbering in the names, description in

chapters 9.3÷9.5

36/40/44:

tun1

/

2

/

3

type of

PID tuning (autotuning)

0:

oFF

=disabled, 1:

Auto

=smart logic, 2:

S tEP

= step response method

(fast), 3:

oSct

= oscillation method (longer),

chapter 9.4

oFF

37/41/45:

Pb1

/

2

/

3

Pb

proportional band

0.1

÷

1800

or

1

÷

9999

units

(2)

1.0

°C

38/42/46:

ti1

/

2

/

3

integral time

Ti

0÷

3600

s, PID algorithm integral action time,

0

turns off the

integral element

0

sec.

39/43/47:

td1

/

2

/

3

derivative time

Td

0

÷

999

s, PID derivative action time,

0

turns off the derivative

element

0

sec.

V. CONFIGURATION OF THE PROCESS CONTROLLER

(programmable operating characteristic, ramping), submenu

ProG

, description -

chapter 9.6

48/53/58:

tYP1

/

2

/

3

stage

type 1/2/3

0:

Grti

stage consisting of 2 segments: reaching the setpoint

11:

SEt1

/

2

/

3

with the

slope

defined

by

parameter

49:

GrA1

/

2

/

3

(ramping) and countdown (50:

tiM1

/

2

/

3

) after reaching it

Grti

1:

tiME

countdown of time after reaching the setpoint

SEt1

/

2

/

3

(

±

H

/2)

2:

toti

countdown of time for the entire stage (regardless of the

setpoint)

3:

EndL

continuous - no time limit

4:

StoP

end - the last stage of the program, available only for stage 2/3

49/54/59:

GrA1

/

2

/

3

slope

of the segment of the

stage 1/2/3

pace of changes (gradient) for the 1st segment of the type stage

Grti

,

ramping,

-30.0

÷

30.0

°

C/min or -

300

÷

300

units/min

(2)

1.0

°C/min

50/55/60:

tiM1

/

2

/

3

time

for

stage

1/2/3

0

÷

1440

min,

duration of the

segment for the stage with

countdown

60

min

51/56/61:

PSE1

/

2

/

3

control

algorithm for step 1/2/3

1:

onof

=ON-OFF with hysteresis, 2/3/4:

Pid1

/

2

/

3

=PID with parameter set

1/2/3 (

chap. 9.3

, not

recommended

for the

stage

Grti

-

gradient

may

disturb

PID operation

)

onof

52/57/62:

ASt1

/

2

/

3

state of

the auxiliary output

during

stage 1/2/3, 63:

AStE

after

the completion of stage 3

1:

oFF

= disabled, 2:

on

= enabled, 3:

hAnd

= manual mode with a set output

signal level (parameter 67:

HSEt

), selection of the auxiliary output (1/2/3) is

defined by the parameter 9/16/23:

ctY1

/

2

/

3

=

PrGA

oFF

VI. KEYS, ACCESS OPTIONS AND OTHER CONFIGURATION PARAMETERS

, submenu

othE

64:

FunF

function

of

[F]

key

65:

Funb

function of the

binary input

BIN

66:

FunS

additional

function of the

[SET]

key

1.

detailed description in

chapter 7.1

)

2.

values 3÷8 ( quick

manual mode) interrupts

and resets the tuning and

0:

nonE

inactive - device status (description,

chapter 7, point a

)

nonE

1:

Set3

step change of the

setpoint

with the set of

parameters for

outputs

1

and 3

(day = 11:

Set1

/night = 25:

Set3

)

,

both outputs

work

the

same

(copy)

2:

bLoc

keyboard lock

,

messages

bLoF

(stop)/

bLon

(start,

default)

3:

hd1A

5:

hd2A

7:

hd3A

unconditional manual

mode

for

the output

1/2/3

with

the output

signal level (MV) set by

parameter 67:

HSEt

,

messages

hnd1

/

2

/

3

(start)/

hoF1

/

2

/

3

(stop)

start (unchanged) with an initial value

for 67:

HSEt

taken from the current

automatic control mode

4:

hd1w

6:

hd2w

8:

hd3w

start (step) with the preset value of

parameter 67:

HSEt

9:

cLEA

(also

10/11)

deleting errors and alarm memory (LATCH) of the

STB

safety

controller with the message

cLEA

or

none

(when there are no

errors and alarms)